Applicable Industries:Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Other

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:Bearing, Gearbox, Motor, Gear

Brand Name:Forward

Place of Origin:Henan, China

Voltage:220v, 220v 380v 110v

Power:0.75kw, 0.75kw

Weight:60 KG

Warranty:1 Year

Application fields:Dairy products factory, Commercial catering, Flour mill, Winery, Cooking oil factory, Cannery, Beverage Factory, Seasoning plant, Frozen food Factory, Snack food factory, Bakery

Machinery Function:Peanut peeling

Raw material:peanut

Output product name:peanut peeling machine

Name:peanut skin peeling machine

Application:Peeling roasted peanut

capacity:100kg/h

Material:Stainless Steel

Feature:High desquamate rate, low crushing rate

machine size:950*360*1000mm

Usage:Food Industry Equipment

Final product:peanut peeling machine

After Warranty Service:Video technical support

Local Service Location:None

After-sales Service Provided:Video technical support

Certification:CE

200-600kg per hour wet and dry type Almond Skin shelling Machine/Wet Hazelnut Skinning remove Machine/Peanut Processing Machine

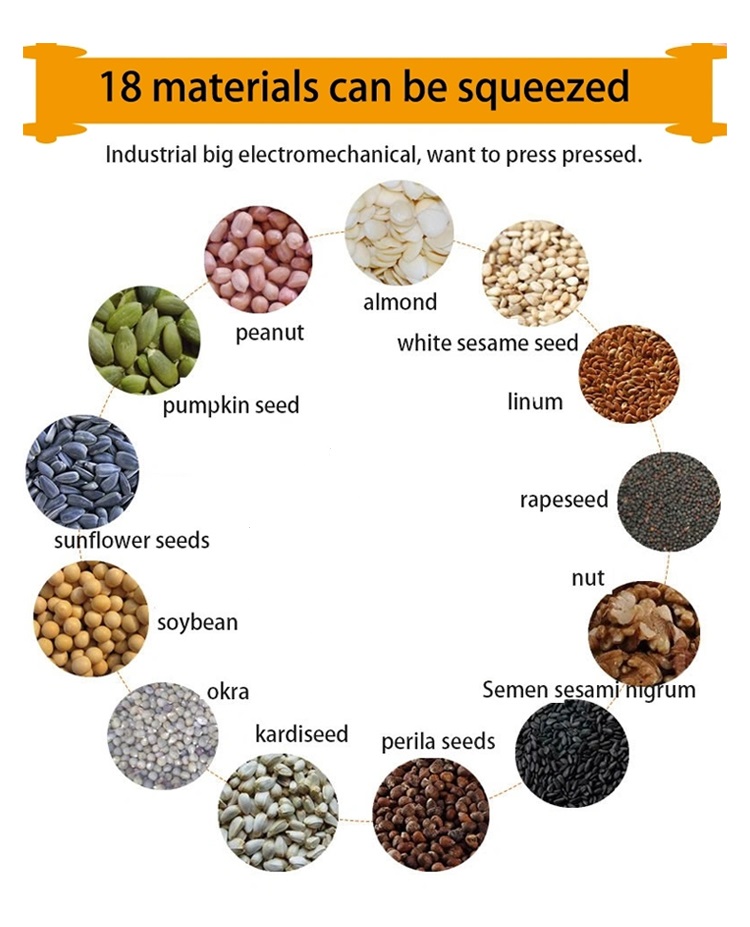

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Raw material

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Working priciple

Working priciple

Complete Edible Oil Manufacturing Unit includes♦ Cleaning process : Use vibration cleaning sieve and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc.♦ Crushing Process: This Process is mainly to crush the peanut , as the peanut is big ,it is not easy to press .We must crush the peanut to 6-8 pieces,then we need to peel .The rate of peel is about 90%.♦ Flaking Process : After crush and peel ,we need to flake the crushed sunflower , which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..♦ Cooking Process: After the flaker,we need to cook the flaked sunflower , control the moisture at 5-7% ,the temperature is 110-115degree.♦ Oil-pressing : After all the pretreatment , pre- press the sunflower , the oil can be extracted about 76% .♦ Primary Oil Filtering Process: after the oil pressing, the crude oil will be primary filtered and for store to tank or for next process of oil refinery.

Advantage

Advanced motor and gearToppest gears and motors in domestic marketManufactured by Liuhui factory, one of the most famous heavy industry bases in China. Machines manufactured by it in better quality and lower price.High-level screw ringsAdopted advanced rings. Rings can help achieve higher extracting efficiency, more durable than plates. Plates machine will be easily broken, also lower extracting rate. Strong and reliableCarbon steel, thickness of steel can reach 3mm, much heavier than any other factories’ machine proving better material and quality, which can help to achieve longer service life.High oil yieldlow residual in cakes, generally under 7%. Other brands usually about 10%. And also, because of the temperature in barrel of our machine under 80 degrees, the protein content in cake is much more higher.

Product Specification

Product Specification

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

Company Profile

Our company is a large-scale modern manufacturing company specialized in the R&D, manufacturing and sales of food oil processing machinery, which covers an area of 18,000 square meters. Numerous plants are installed in Netherlands, Kazakhstan, Malaysia, Nigeria, Nepal, Bangladesh, Sri Lanka, Indonesia, Bulgaria, New Zealand, Peru, South Africa, and Saudi Arabia, etc..We have our own showroom to showcase our products.You can meet all products there.Welcome to Company.

Service

Pre-sale services:1. Providing professional technical support.2. Send the product catalog and instruction manual.3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!4. Personal call or visit are warmly welcome.Sale of services:1. We promise honest and fair, it’s our pleasure to serve you as your purchasing consultant.2. We guarantee punctuality, quality and quantities strictly implement the terms of contractAfter-sales service:1. Where to buy our products for 1 years warranty and life long maintenance.2. 24-hours telephone service.3. A large stock of components and parts, easily-worn parts.

FAQ

1. Q: Are you a trading company or a manufacturer ? A: We are a manufacturer, which has long experience in this industry. 2. Q: How can I get to your company ? A: You can get a flight to Xinzheng Airport. We are just about 40- 50mins away from Xinzheng Airport. 3. Q: How long is your guarantee ? A: One year(Calculated from the equipment arrives the customer’s side.). After this period we will definitely support you when needed. You will be welcome to contact us with any problem may happened. 4. Q: Will you send engineers to install the plant?A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.5. Q: Do you have some foreign customers using your equipment?A: yes, we have our company has established business relationships with customers in Russia, German, Slovakia, Ukraine, Vietnam, Pakistan, the Philippines, Indonesia, Thailand, Pakistan, Egypt ,Iraq, Jordan, Saudi Arabia, Syria, Libya etc.