Applicable Industries:Food & Beverage Factory, Farms, Food Shop

Showroom Location:Brazil, Indonesia, Russia, Chile, Algeria, Kazakhstan

Condition:New

Application:Food, Beverage, Commodity, Chemical

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220/380V

Place of Origin:China

Brand Name:paima

Dimension(L*W*H):3880*2800*2500mm

Weight:5000 KG

Warranty:2 years

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

Filling Material:Beer, Milk, Water, Oil, Juice

Filling Accuracy:+/-2mm

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

Name:3 in 1 washing filling capping machine

Capacity:2000-24000BPH

Usage:Beverage filling

Feature:High Precision Filling Level

Material:SUS304/316

Processing Types:Automatic Bottle Filling Sealing Machine

Filling range:200-2000ml

Control:PLC+ Touch Screen

Filling head:8 – 60 Heads

Bottle type:PET Plastic Bottle Glass Bottle

4 in 1 small auto NFC fresh fruit apple orange mango juice filling bottling capping machine plant production line equipment

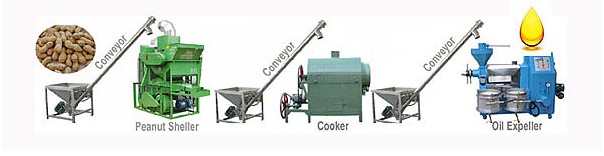

This oil press with cold and hot pressing function,fit for more than 20 kinds of materials:such as Peanuts,sesame,walnut,rapeseed,sunflower,soybeans,castor beans,pumpkin seeds,eans,watermelon seeds,moringa seeds,pine nuts,hazelnut kernels,almonds.

Raw material

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Working priciple

Working priciple

As for oil extractionmachine, that is using oil extraction method and choosing an organic solvent which can dissolve oil, after contacting with pretreated oil–spray or immersion, so that oil can be extracted. As the boliling point of solvent and oil are different, after evaporation and stripping, the solvent are evaporating and we can get crude oil.Solvent– Extractor–Mixed oil — 1st and 2nd evaporation — Stripping tower — Crude oil– Wet meal — DTDC toaster — Meal

Advantage

1.This type of automatic screw cold oil making press machine equipment is able to do both cold press and hot press.2.Widely-used:the oil press can be used for more than 20 kinds oil crops.3.Pure oil quality:the vacuum oil filtering is used to remove residue so as to ensure the pure oil quality and meet the standard of health quarantine.4.Save space and labor:an area of 10-20 square meters workshop and 1 to 2 worker can meet the need of production.5. Good quality, durable: made of high-quality materials, high temperature resistance, strong wear resistance.High hardness, high strength, no deformation, long service life. 6. Easy to operate: simple structure, easy to use.One person can complete the entireoperation process .7. Factory direct selling, cost-effective: price concessions, more than one machine, one time squeeze net. 8.Mature technology: mature technology, advanced processing equipment and precise internal structure are adopted. 9. Clean, energy efficient, hygienic: The filtered oil can be used directly and the extracted oil is beautiful.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

our company as manufactures for oil press machine,we have more than 20 years of experience, our products all achieved patent certificates, and our company has many times achieved the title of honor: ” Observe Contract and Keep Promise” ” Quality,Trustworthy Product” “Good After-sales Service Reputation”, etc.it developed from a pure equipment manufacturers to a high-tech enterprises includes research&development, manufacturing, marketing, service and e-commerce. Our group is composed of highly dedicated employee from around the world, ensuring the success of customers and close cooperation. We are committed to mining to provide customers with world-class products and services. “Customers Trust, Preferred Supplier” is the persistent pursuit of our people.

Service

Pre-Sales Service* professional sales team.* 24 hours online service.* visit our Factory.After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

FAQ

Usually the delivery time is 3-15 working days after prepayment received.Q7: What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you