Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Application:bottle

Plastic Processed:PE, PP, HDPE, PC, ABS, PVC, EVA, PA

Place of Origin:Guangdong, China

Brand Name:LESHAN

Dimension(L*W*H):4400X2450X3600(2150)mm

Clamping Force (kN):80

PLC Brand:Siemens

Screw L/D Ratio:24

Screw diameter (mm):65 mm

Output (kg/h):60 kg/h

Automation:Automatic

No. of Screw Heating Zone:3

Screw Heating Power(kW):7 kW

Extruder Motor Power(kW):15 kW

Mold Platen Size(Width)(mm):300 mm

Mold Platen Size(Height)(mm):400 mm

Air Pressure(MPa):0.8 MPa

Air Comsumption(m³/min):0.23 m³/min

Die Head Heating Power(kW):5 kW

Accumulator Capacity(L):100 L

Power (kW):50.56

Weight (T):8.5

Key Selling Points:Automatic

Warranty:1 Year

Applicable Industries:Manufacturing Plant

Showroom Location:None

Automatic:Yes

Model Number:SCJ 65-45-25U2x2.5F

After-sales Service Provided 1:Field maintenance and repair service

After-sales Service Provided 2:Field installation, commissioning and training

After-sales Service Provided 3:Free spare parts

After-sales Service Provided 4:Video technical support

After-sales Service Provided 5:Online support

After Warranty Service 1:Video technical support

After Warranty Service 2:Online support

After Warranty Service 3:Spare parts

5L Best Supplier Full Automatic PE HDPE Drum Extrusion Lubricant 1L Making Engine Oil Bottle Blow Molding Machinery

Pretreatment Applicable oil: soybean, rice bran, sunflower, rapeseed, cottonseed, walnuts, corn germ, peanuts, copra, castor bean, palm kernel, palm nuts, sesame, olive and the like.

Raw material

Hydraulic Screw Cold and Hot Oil press machine is suitable for the pressing of various materials: sesame, walnut, chestnut, cashew, pine nuts, baobab seed, cocoa butter, Argan nuts, avocados, olives, grape seeds, camellia seeds, prickly pear seeds etc.

Working priciple

Working priciple

6YL-68 oil making machine is a screw type pressing machine that is capable of extracting oil within a caged barrel-like cavity. Usually, raw material enters it from the feeder. Then, the machine utilizes strong frication and continuous pressure to compress the raw material. After compression, the oil will come out from a small oil outlet. More importantly, the seed fiber solids and other larger impurities can’t pass through the small oil outlet. And, the extracted seeds will be pressed into hardened oil cakeand discharged from your oil making machine.

Advantage

With Our core part the outstanding press chamber and special feeding and transmitting power systems,we realize the advanced multistage press and gradual pushing compress technology, which add more pressure points and strengthen higher press degree of the materials. Our reasonable and unique design of the inner chamber, more advanced compared with the traditional, for example, the cold press machine is main bar Exhaust type leakage design out of the press chamber , but the hot press machine is main the round Exhaust type leakage design. The other difference between the hot and cold press is the feeding and transmitting system, our super design;

Product Specification

Product Specification

| item | value |

| Voltage | 380V |

| Dimension(L*W*H) | 1200x550x1050mm |

| Weight | 130KG |

| Max Capacity | 500 kg/h |

| Product name | Oli Press Machine |

| Raw material | Palm Fruit |

| Function | Press Oil Seeds |

| Application | Edible Oil Production |

| Advantage | Energy Saving |

| Keyword | Small Capacity Oil Press Machine |

| Material | 304 Stainless Steel |

Company Profile

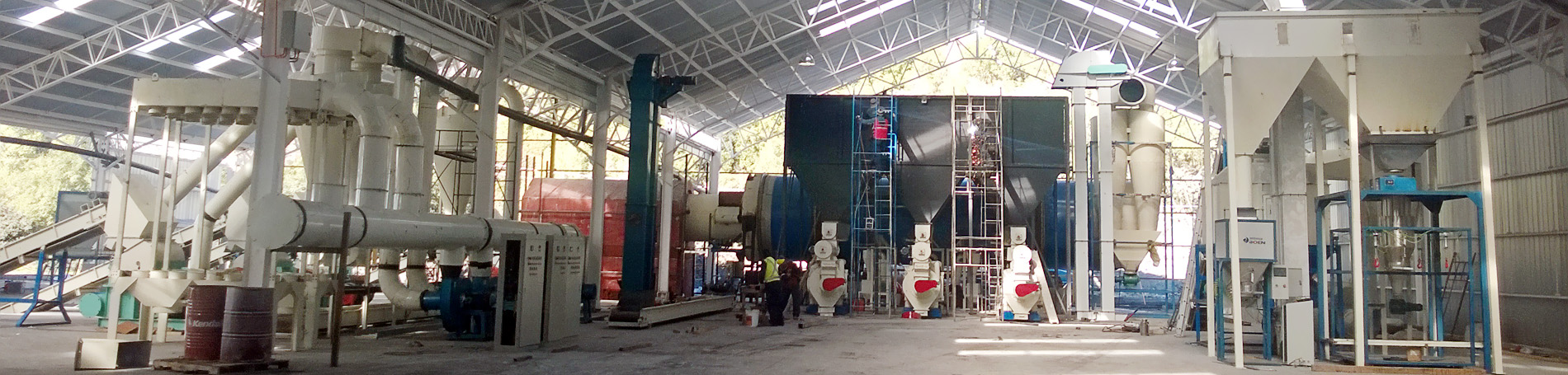

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Service before sale1.24 hours online.Your inquiry will be quickly replied by email.Also all questions with you can be sloved by any online chatting tools.2.Professionally and patiently introduction, details pictures and working video to show machine.Service on sale1.Installation:quality and quantity guaranteed;completion of hand over.2.Acceptance: acceptance test;accepted deliverables.3.Technical tranining:on-site installation and products training.Service after sale1.Technical service:long time technical service.2.Accessories supplying:supplying spare parts with cost price.3.Client review:call-back;regular return visit.4.24 hours online to solve any problem .

FAQ

1.Q: How about the after service?A: We have a strong team, special for after service. We can arrange engineers to do service for you. And we insist “Quality is Life”.2.Q: Are you factory or trading company? Where is your factory located?A: We are a factory in machine development; Our factory is located in Zhengzhou Henan Province, welcome you come to China and have a visit.3.Q: Do you have English install step or vedio ?A: Sure, we have.Will send it to you when you need it.4.Q: How does your factory do regarding quality control?A: Quality is priority. We always attach great importance to quality controlling from the beginning.5.Q: why choose Our Machinery?A: We are one of leader in this field(in China). Our quality products and servicehave enabled us to expand our market from china to more than 60 countries.6. Q: How long will you send the machine after I pay?A: Normally, about 5-7 days. Also, if urgent, pls contact with us.7. Q: How can I pay?A: By T/T(wire transfer),Western Union, Money Gram, Alibaba Trade Assurance.Pls feel free to contact us if you want get more information or any question ! !