Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Food, Beverage

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric+pneumatic

Voltage:3800V

Place of Origin:Henan, China

Brand Name:K Snow

Dimension(L*W*H):4000x1500x1650mm

Weight:2000 KG

Warranty:1 Year

Key Selling Points:automatic

Machinery Capacity:150BPH

Filling Material:Milk, Water, Juice

Filling Accuracy:0.5%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Pump

filling nozzle number:8

volume counting way:microcomputer measurement and control flow type

filling nozzle anti-drip device:yes

touching part material:304ss

cooperated equipment:air compressor

working air pressure:0.5-1Mpa

PLC panel:yes

application:oil, Petroleum, Chemical

filing range:100-1000ml,1000-6000ml

Function:volume couting–filling–capping–labeling–date printing

Automatic 8 filling nozzles cooking oil edible oil filling packing machine line

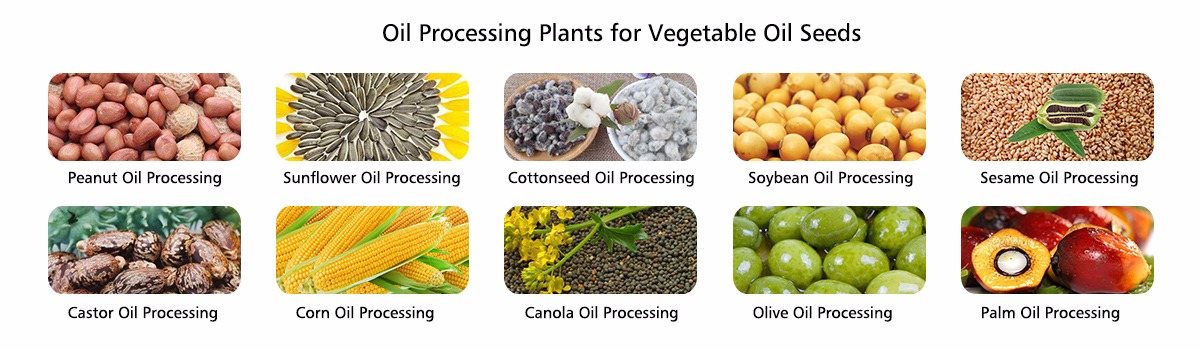

Automatic Cold Pressed Oil Extraction Castor Walnut Press Palm Refining Groundnut Peanut Oil Making Oil Expeller Machine is Suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame, sesame seed, tea seed, walnut, olive, corn germ, rice bran, tea seed, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

Suitable for sunflower seeds, rapeseed, oleander, soybean, tea seed, pepper seed, sesame, peanut.

Working priciple

Working priciple

Cold pressing and hot pressing mode for oil press customer consultation:1. Cold pressing refers to the direct pressing of materials without stir-frying;2. Hot pressing means that the material is heated to 60-80 degrees and then put into pressing;3. No matter cold pressing or hot pressing, our oil press must preheat. Only when the press chamber is preheated to about 200 ℃ can the oil be separated from the material.If the machine is not heated, the material will only be extruded into a paste, and the grease cannot be separated.4. Under the cold pressing mode of the material, the normal temperature of oil coming out is about 40°, and the nutrients will not be lost. Under the material hot pressing mode, the oil yield will be higher, the oil will be more fragrant, the oil will come out at a temperature of 60-80 degrees, and some nutrients will be lost.5. Therefore, the hot pressing mode is generally suitable for pressing rapeseed, peanuts and other low-value edible oils, and the pursuit is oil yield and aroma of cooking;The cold pressing mode is generally suitable for pressing walnut oil, flaxseed, almond, olive kernel and other high nutritional auxiliary oil to ensure the nutrition is not lost.

Advantage

(1) High oil yield , obvious economic benefit.(2)Residual oil rate in the dry meal is low.(3)Improving the quality of the meal and oil.(4)Low processing cost , high labor productivity.(5)High automatic and labor saving.And more other advantages please contact me now,we will provide profession program for you,and we accept custom according your requirements.

Product Specification

Product Specification

| Project name | capacity | suitable for raw material |

| oil pressing production line | 10–800t/d | sunflower seed, soybean, peanut, sesame, corn germ, tea seed, rapeseed, cottonseed, etc |

| oil solvent-extracting production line | 30–800t/d | pressed oil cake, soybean flakes, rice bran pallet, etc. |

| oil refining production line | 3–500t/d | all kinds of vegetable oil |

| palm oil mill production line | 5t/h–90t/h | palm fruit bunch |

| oil fractionation production line | 20–500t/d | refined palm oil |

| Oilseeds protein, phospholipids | 50–500t/d | soybean meal, etc. |

| grain deep processing line | 20–1000t/d | corn, wheat, beans, etc. |

Company Profile

Our Company supply the complete set of Cooking oilproduction line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, corn germ oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, moringa seeds oil production line and other vegetables oil processing machines.

Service

Service before sale1.24 hours online.Your inquiry will be quickly replied by email.Also all questions with you can be sloved by any online chatting tools.2.Professionally and patiently introduction, details pictures and working video to show machine.Service on sale1.Installation:quality and quantity guaranteed;completion of hand over.2.Acceptance: acceptance test;accepted deliverables.3.Technical tranining:on-site installation and products training.Service after sale1.Technical service:long time technical service.2.Accessories supplying:supplying spare parts with cost price.3.Client review:call-back;regular return visit.4.24 hours online to solve any problem .

FAQ

a discount.Q8: Do you have machines in stock?Yes, we have some models oil press in stock.Q9: How will my order be packed, can you provide the installation service?Packed in plywood case. We will send English manual. If the customer need, we will send one engineer for assembling and training for workers.