Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Construction works , Energy & Mining

Showroom Location:United States, Germany, Malaysia

Condition:New

Application:Food, Beverage, Chemical, Machinery & Hardware, MEDICAL

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic, Metal, Wood

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V,50hz/60hz

Place of Origin:Guangdong, China

Brand Name:LaoYiDuo

Dimension(L*W*H):2700mm*1500mm*2000mm

Weight:1300 KG

Warranty:2 years

Key Selling Points:Automatic

Machinery Capacity:400BPH

Filling Material:Other, Water, Oil

Filling Accuracy:99.8%

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, Pressure vessel, Pump, Other, PLC, Gear, Bearing, Gearbox, Engine

Filling speed:500 barrels / 1 hour

Capacity:3KG—30KG

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:United States, Germany, Malaysia

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE

Automatic bucket filling machine Lube Oil Barrel Filling Machine 500 Barrels / 1 Hour Upper Weighting 3KG-50KG

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

Raw material

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

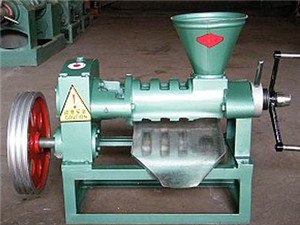

Working priciple

Working priciple

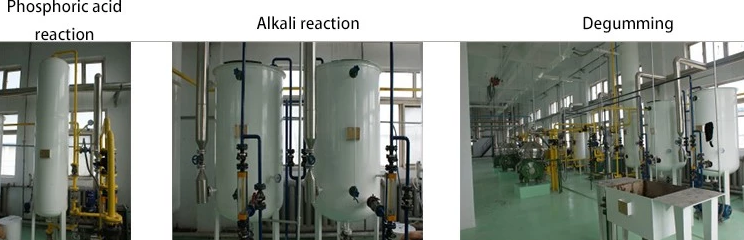

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantage

Green health & Energy saving & Save labor and long life & High oil recoveryWidely used & Small footprint & Quick cost recovery

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We are a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.

Service

1. We can manufacture according to your sample, design and technical indexes;2. We’ll provide you the whole program solution according to ur local customs, oil crops, local market demand;3. After sale, we’ll send our professionals to install and debug the machinery till you have learned all by yourself.

FAQ

QHow can I get the sample to check your quality?AAfter price confirmation, you can require for samples to check our product’s quality.QWhat can I get the price?AWe usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.QWhat is your term of delivery?AWe accept EXW, FOB Shanghai or FOB Qingdao. You can choosethe one which is the most convenient or cost effective for you.QWhat about the lead time for the production?AHonestly, it depends on the order quantity and the season you place the order. In common 7~15 days.