Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

Showroom Location:Egypt, Viet Nam, Saudi Arabia, Mexico, Morocco, Sri Lanka, Malaysia, Australia

Condition:New

Application:Food, Beverage, Machinery & Hardware

Packaging Type:Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Bags

Packaging Material:Plastic, Paper, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380v/220v

Place of Origin:Shanghai, China

Brand Name:leadworld

Dimension(L*W*H):2200*1020*2250mm

Weight:2500 KG

Warranty:1 Year

Key Selling Points:Long Service Life

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, 100-200BPM

Filling Material:Beer, Other, Milk, Water, Oil, Juice, Powder, fruit&vegetable

Filling Accuracy:±0.5-1%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:More than 5 years

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

Product name:Automatic sliced cucumber filling production line

Bottle type:PET Plastic Bottle

Capacity:100-200pcs/min

Filling range:50ml-5000ml

Function:Automatic Filler

Keywords:Fillng Machine

Processing Types:Automatic Bottle Filling Sealing Machine

Advantage:High Effiency

Filling speed:10-30 Bottles/min

Feature:High Precision Filling Level

Automatic Canned PIckle Cucumber Process Line Sliced Cucumber Filling Production Line

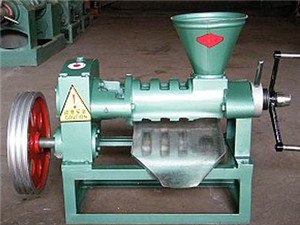

This screw cold&hot press series can process sesame seed, rapeseed, peanut, soybean, cottonseed, almond, Tung-oil seed, sunflower seed, tea seed, walnut, caster seed, Perillaseed , Hazelnut,oil palm, oil olive, avocado, pomegranate seed , pistachio nut, neem seed, coconut, totally about 150 types of seeds , nuts,beans , fruits and oil crops;

Raw material

Raw materials:It is suitable to kinds of raw materials , such as sesame, sunflower seeds, soybean, peanut, coconut, etc

Working priciple

Working priciple

Screw expeller pressing is to separate the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of screw oil expeller, they have similar theories in screw expeller pressing.Because the screw type seed oil expeller is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process.

Advantage

Product Features1. The pressure value is greater, the oil output rate is higher, and more safety.2. Hard chrome electricity instead of decorative chrome.3. The load-bearing panel and load-bearing column are made of special steel instead of ordinary steel to ensure durability and safety.4. Each key parts have professionally inspection. No defective plate is allowed for equipment manufacturing.5. Use high-quality motor to ensure strong heart power. Low failure rate.6. Patent barrel, increase the oil output on the premise of ensuring strength.7. Reduce the height of the bottom plate of the main engine, and improve the dust-proof effect of the fuel tank.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you!

Service

1.We are a factory manufacturing edible oil machine, best production capability, best quality control, best Service.2.100% quality control inspection for every machine.3. Competitve price.

FAQ

Q: How long is the smart oil press working once, how much material can be squeezed at one time?A: The working time is not limited.Q: Can the oil press be hot pressed and cold pressed? What is hot pressing? What is cold pressing?A: Yes. The hot press oil rate is higher than the cold press, but the nutritional value is not as healthy as cold pressed oil. Hot pressing is the fryed and heated material. The cold press is that the raw material is not heated before being put into the machine. The direct press of the oil press is cold pressing.Q: How much oil can the smart oil press press at one time? What is the oil yield?Answer: According to the material and operation mode, the different operation modes of different materials have different effects.Q: Can the oil press machine mixes and squeezes oil?A: Yes.Q: What kind of material is the squeezer made of? What material is the external ?A: The squeezed press bar is made of food grade 304 stainless steel, which has high strength and good wear resistance. It does not produce chemical reaction when pressed. The exterior is made of stainless steel, resistant to high temperatures, dirt and easy to clean.