Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Other

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Chemical, Oil

Packaging Type:Bottles, Barrel, case

Packaging Material:Plastic, Glass, Other

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220v/308v

Place of Origin:Shanghai

Brand Name:Ipanda

Dimension(L*W*H):1.2m*0.8m*1.8m

Weight:500 KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 6000BPH, 2000BPH, 1000BPH

Filling Material:Oil

Filling Accuracy:99.87%

Marketing Type:New Product 2020

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Bearing, Gearbox, Engine

Product Name:oil filling and capping machine 1 – 25 liters

Bottle Type:PET Plastic Bottle Glass Bottle

Capacity:1000-6000BPH

Material:SUS304/316L

Filling Nozzles:2/4/6/8/10/12(customized)

Filling Volume:100-5000ml

Power:2.2KW

Air Pressure:0.4-0.6MPa

Control:PLC+ Touch Screen

Automatic Edible Cooking Vegetable Coconut Mustard Bottle Filler Capping Palm Oil Filling Machine

Suitable for sunflower seeds, rapeseed, oleander, soybean, tea seed, pepper seed, sesame, peanut.

Raw material

This oil press machine can be used to make cooking oil with raw materials such as flax seed, peanut, rapeseed, sesame,sunflower, etc.

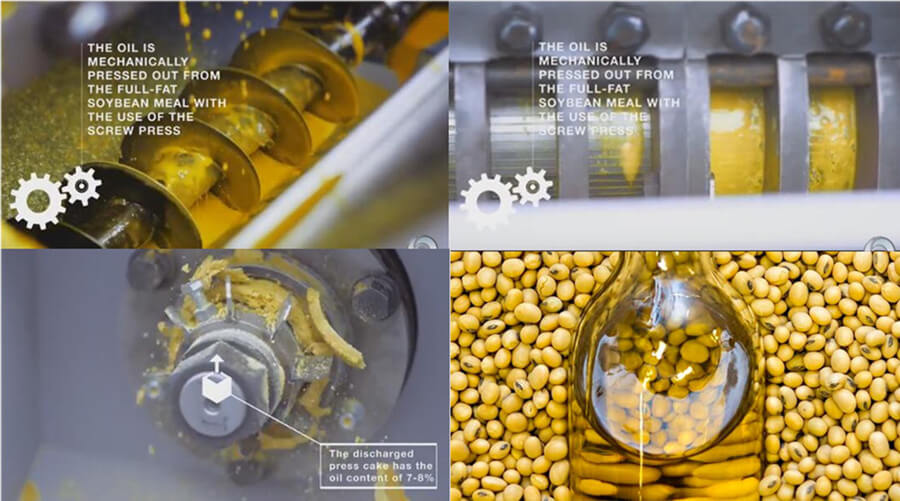

Working priciple

Working priciple

The technology flow of cooking oil solvent extraction machine:The process is like oil extracted – wet meal desolvation – mixed oil vaporation – stripping by steam – solvent recoveryMaterial embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing ↓Mixed oil→Filter→Negative pressure evaporation → Crude oil ↓Solvent recovery

Advantage

1.Advantage: nice shape, highly structured, easy installation, , fast warn-up and high oil output rate 2.New type:this kind of machine is our latest environment protection oil press.3.Main feature:this kind of combined oil press machine mainly has 3 parts: electric control box to control the machine working, oil pressing part, and vacuum filtering part for clearing oil.4.Function: hot press and cold press are available.5.Structure:6YL-S series integrated oil press machines are designed on the basis of the advantage of 6YL-T series oil press with all stainlesss steel body6.Suitable place:this kind of machine is situable for small-medium factory and supermarket.

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Service before sale1.24 hours online.Your inquiry will be quickly replied by email.Also all questions with you can be sloved by any online chatting tools.2.Professionally and patiently introduction, details pictures and working video to show machine.Service on sale1.Installation:quality and quantity guaranteed;completion of hand over.2.Acceptance: acceptance test;accepted deliverables.3.Technical tranining:on-site installation and products training.Service after sale1.Technical service:long time technical service.2.Accessories supplying:supplying spare parts with cost price.3.Client review:call-back;regular return visit.4.24 hours online to solve any problem .

FAQ

Q:Are you a manufacturer or a foreign trade company?A:We are a manufacturer.Q:What if I could not operate this product?A:There is peration video and manual for you. If necessary, we will send engineers to train for you personally.Q:Can you provide more information about production and quote the best price?A:Of course, but first we have to confirm your needs. According to your needs, we will choose the right product for your reference. When we determine one or several products, we will quote you the best price.Q:How to place an order?A:First send us the enquiry below, including the device name, daily production, work hours, main processing materials, etc., then our sales manager will send you the information for your reference.Q:How long does it take to receive my product?A:It is not yet possible to determine the time because the shipping distance and production cycle are uncertain.our business manager will recommend the appropriate transportation route for you to ensure safe and fast delivery of the goods.Q:How is the quality of your products guaranteed?A:After the completion of production, our quality inspection can not test the product. If you need it, we can provide third-party testing service to ensure the stable production of the equipment.