Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:PLC

Condition:New

Automatic Grade:Automatic

Place of Origin:Guangdong, China

Brand Name:Santai

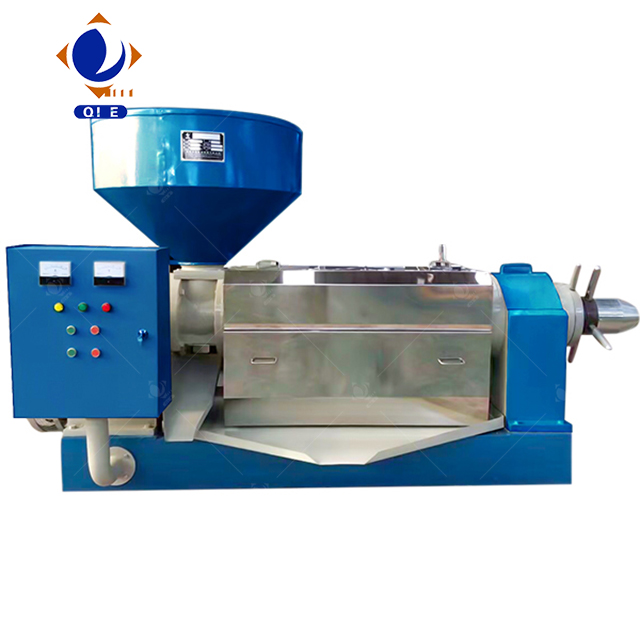

Power:1.5KW

Weight:600KG

Dimension(L*W*H):1555*750*1000

Warranty:3 years

Product name:Plate and Frame Filter Press

Filter area:4 M2

Cake thickness:25mm

Filter Plate size:500*500

Filter chamber volume:50KG

Filter plate thickness:50mm

Filter Plate:10pcs

Bottom center length:1103mm

Item:Membrane Brewery Mash Fitler Press

Keywords:Liquid Filter Machine

After Warranty Service:Video technical support

Local Service Location:None

After-sales Service Provided:Online support

Certification:IOS9001,CE

Automatic membrane filter press with high quality

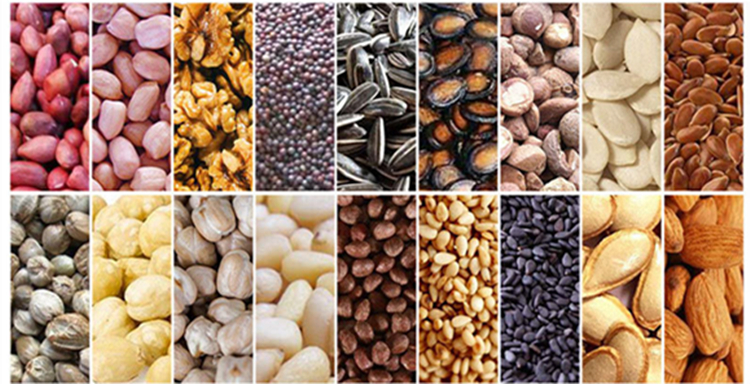

Oil refining workshop application :Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil all refined oil.

Raw material

This oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ,etc.

Working priciple

Working priciple

Palm oil is divided into red oil and white oil. Red oil is pressed by the palm fruit pulp, mainly for edible oil. White oil is pressed by the palm kernel, mainly for industrial oil. Red oil is made by the fresh palm fruit string, each string is 10Kg to 20Kg. The fruit string should do the high temperature cooking, Threshing the fruit for the string, heating and pressed by our palm oil press can get red oil with water and stag, with separting and filting get red palm oil

Advantage

1.Large processing capacity2.Combined Steaming & Cooking3.Lower energy consumption4.Automatic and Continuous Operation5.Flexible production6.Higher quality oil and cake & Steady oil yield7.Perfect Construction, Simple Control and Durable service

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.In recent years, the company has completed hundreds of projects involving oil pre-pressing, extraction, oil refining, animal oil refinery processing, small species of oil refining and biodiesel, a project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery, 100t / d of biodiesel and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Pre-sale services1) Selecting equipment type;2) Designing and fabricating the products in accordance with the special requirements of the clients;3) Training technical personnel for our clients;4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.After-sale services1) Assisting the clients preparing for the first construction scheme;2) Installing and testing the equipment;3) Training the first-line operators on site;4)Supplying spare parts with cost.

FAQ

1. Q: Which kind of raw materials can be process?A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-3000 tons per day. We can manufacture as customized order. 3.Q: How long is your guarantee ?A: One Year guarantee. We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How about the quality of your products ?A : Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: We will send our engineers to local place to help installing the machine and provide technical guidance.6.Q: What’s the payment terms?A:T/T, Trade Assurance, L/C, Cash etc.