Showroom Location:Indonesia

Condition:New

Usage:OLIVE OIL

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:6-8t/24h

Place of Origin:Henan, China

Brand Name:AOLS

Voltage:Customised

Dimension(L*W*H):1800*1200*1500MM

Weight:1100kg

Warranty:1 Year

Key Selling Points:Long Service Life

After Warranty Service:Online support, Spare parts

Local Service Location:Indonesia

After-sales Service Provided:Free spare parts, Online support

Function:Olive Oil processing machine

type:Cold & Hot Pressing Machine

Raw material:Soybean,olive,coconut ,peanut

Keyword:Oil Extraction Equipment

Feature:High Oil Yield Efficiency

Application range:Prickly Pear Oil Press Machine

application:Screw Oil Expeller

Product name:screw oil press machine

Used for:Pressing Oil Seeds

Processing Types:Screw Pressing

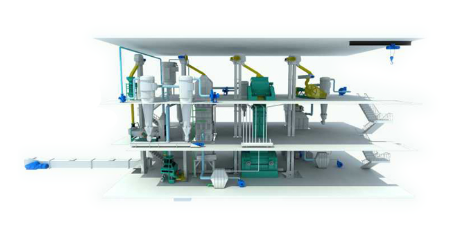

Automatic Mini Home Olive Oil Cold Pressing Extraction Machine Coconut Mustard Flax Seed Oil Press Machine

The Oil press is used to get the edible oil or bio-diesel from vegetable oilseed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, seasame seed, cottonseed, coconut,, etc

Raw material

The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Working priciple

Working priciple

Main Parts Of The Automatic Oil Press Machine:1.screw shaft2.feeder3.pressing cage4.oil pan5.squeezing bolt6.vacuum oil filter system7.electric control system8.heating ring

Advantage

1 Wide application for a great number of vegetable plant seed。 2 Small investment, fewer land space, but with the complete function of oil processing to get higher oil yield.3 Easier to operate, easier to install and commissioning.4 Need fewer labor than single oil press machine, with considerable design, it only needs 2~3 persons to running the whole line.5 The semi- continuous can avoid the unstable material feeding caused by manual and make the worker safety more under the higher temperature working situation6 We use screw pressing to obtain high-quality oil, which is safer and healthier. The storage time of refined oil is longer.

Product Specification

Product Specification

| Model | ZY-80 | ZY-100 | ZY-125 | ZY-150 | |

| Power | Power | 5.5kw | 7.5kw | 15kw | 22kw |

| Pump | 1.1kw | 1.1kw | 1.5kw | 2.5kw | |

|

Heater |

2KW | 2.2kw | 2.8kw | 4.5kw | |

| Capacity | 80-130kg/h | 140-280kg/h | 350-400kg/h | 350-450kg/h | |

| Weight | 780kg | 1100kg | 1500kg | 1500kg | |

| Dimension(mm) | 1700*1200*1500 | 1800*1300*1680 | 2100*1400*1700 | 2500*1750*2000 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.In recent years, the company has completed hundreds of projects involving oil pre-pressing, extraction, oil refining, animal oil refinery processing, small species of oil refining and biodiesel, a project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery, 100t / d of biodiesel and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Acceptance standardUnless stipulated in the technical documents accordingly, technology acceptance standards of designed main parts are in accordance with relevant state departments issued current relevant standards. providing main parts technology acceptance standard of technical design. Technical serviceDuring rice mill machinery installation, We cooperate with buyer for technological improvement to reach desired results. We explains rice mill machinery performance, structure and operation to buyer related people for free.Quality guaranteed We makes sure our rice mill machinery achieve promised performance with correct installation, commissioning, normal operation and maintenance. In warranty period, for quality problem, we repair and replace defective parts for free(except quick-wear part).

FAQ

QHow can I get the sample to check your quality?AAfter price confirmation, you can require for samples to check our product’s quality.QWhat can I get the price?AWe usually quote within 2 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.QWhat is your term of delivery?AWe accept EXW, FOB Shanghai or FOB Qingdao. You can choosethe one which is the most convenient or cost effective for you.QWhat about the lead time for the production?AHonestly, it depends on the order quantity and the season you place the order. In common 7~15 days.