Showroom Location:India

Condition:New

Usage:Palm Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:30 kg

Place of Origin:Tamil Nadu, India

Brand Name:voc automatic wooden & stone machine

Voltage:5 hp motor

Dimension(L*W*H):6*3.5*5

Weight:800 KG

Warranty:1 Year, 12 Months

Key Selling Points:Automatic

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Not Available

Warranty of core components:1 Year

Core Components:Motor, Gear, Bearing, Gearbox

Oil type:Flax Seed Oil, Soybean Oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil

Max Capacity:20 kg/h

Raw material:Oil Seeds

Capacity:15 Kg

Advantage:High Oil Yield

Function:Oil Pressing

Quality:High Level

Color:Customizable Color

Name:Nethaji Rotary Chekku Machine

Automatic Nethaji SS Rotary Chekku Machine for Hot Pressed and suitable for all edible oil extractions

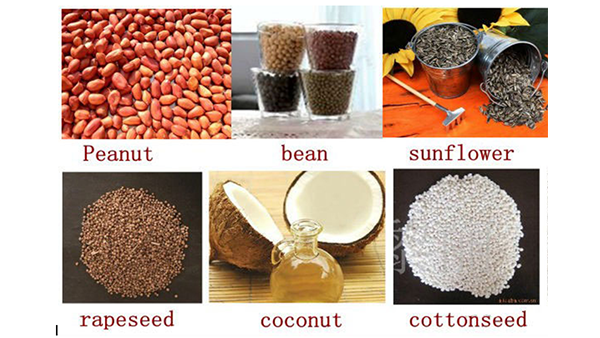

Our screw small coconut oil press machine can process a great many plant seeds, such as peanut, soybean, sunflower seeds, sesame seed, cottonseed, rapeseeds, corn germ, coconut, palm kernel, jatropha seed, hemp seed, castor seed, etc.

Raw material

Although 6YL Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, ,etc.

Working priciple

Working priciple

What is cooking olive coconut sunflower oil making filter press extraction refining machine ?Series of 6YL-100,6YL120 are the electric heating vacumm filter screw oil press machine.The products’ electric heating using internal and external heating at the same time.It also have the function that it can preheat pressing chamber automaticly before squeezing,and control the pressing temperature automaticly during squeezing.In the course of the press,it can filter crude oil by vacuum. At the same time,it can make the oil and slag separated, so that the oil becomes more clear. Through tempering treatment,special steel is more wear-resisting than ordinary steel.Their working life is 5 times than ordinary steel.So that it can make a higher output than other products.

Advantage

1.saving labor 2. suite for sesame press 3. pure oil quality 4. small land-using,low voice 5. used for hot press6.It can press many kinds of crop seeds, such asrapeseeds,soybeans,peanuts,sesame,sunflower,palm fruit ect. with advantages of small power,high oil yield and easy operation.7.It has high efficiency and energy-saving oil press8.2-3 steps process, clean pressing9.Stainless steel is used on the surface to reach the standard of food hygiene.

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

our company as manufactures for oil press machine,we have more than 20 years of experience, our products all achieved patent certificates, and our company has many times achieved the title of honor: ” Observe Contract and Keep Promise” ” Quality,Trustworthy Product” “Good After-sales Service Reputation”, etc.it developed from a pure equipment manufacturers to a high-tech enterprises includes research&development, manufacturing, marketing, service and e-commerce. Our group is composed of highly dedicated employee from around the world, ensuring the success of customers and close cooperation. We are committed to mining to provide customers with world-class products and services. “Customers Trust, Preferred Supplier” is the persistent pursuit of our people.

Service

6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service (paid)5. VIP price for the coming order.

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.