Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2021

Warranty of core components:1 Year

Core Components:Bearing, Gearbox, Motor

Condition:New

Place of Origin:Guangdong, China

Brand Name:XAT

Type:Centrifuge, Food Dehydrator

Voltage:220

Power:0.55

Weight:75 KG

Dimension(L*W*H):600*360*350mm

Year:2021

Warranty:1 Year

Application:Restaurant

Name:Vegetable Processing Machine

Function:Multifunctional

After-sales Service Provided:Video Support, Video technical support

Product name:Food Dehydrator Machine Fruit

Usage:Food Industry Equipment

Material:304 Stainless Steel

After Warranty Service:Video technical support

Local Service Location:None,attrValueId:3270618

Automatic Vegetable Centrifugal Drying Machine centrifugal dehydrator plate manual unloading dehydrator plate centrifuga

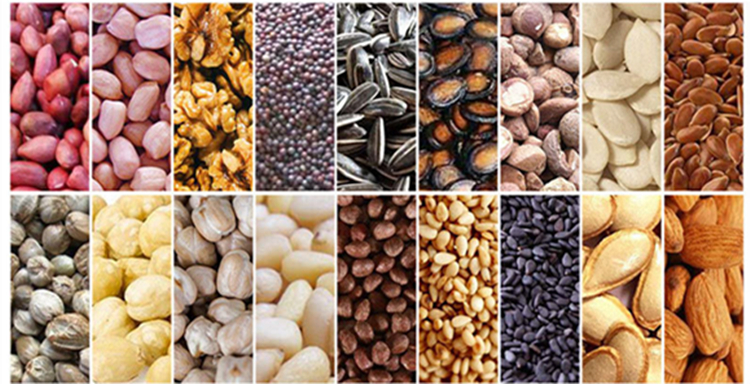

This oil press with cold and hot pressing function,fit for more than 20 kinds of materials:such as Peanuts,sesame,walnut,rapeseed,sunflower,soybeans,castor beans,pumpkin seeds,eans,watermelon seeds,moringa seeds,pine nuts,hazelnut kernels,almonds.

Raw material

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Working priciple

Working priciple

The flow chart process of palm oil processing machinePalm fruit bunches–Sterilizing–Threshing–Digesting–Pressing–Clarifying–Filtering–Drying–Crude palm oil.

Advantage

ure mechanical press, more healthy, purer flavor, 24 hours continuous work, alloy steel structure and parts, high oil extraction rate, easy to operate;

Product Specification

Product Specification

| Project name | capacity | suitable for raw material |

| oil pressing production line | 10–800t/d | sunflower seed, soybean, peanut, sesame, corn germ, tea seed, rapeseed, cottonseed, etc |

| oil solvent-extracting production line | 30–800t/d | pressed oil cake, soybean flakes, rice bran pallet, etc. |

| oil refining production line | 3–500t/d | all kinds of vegetable oil |

| palm oil mill production line | 5t/h–90t/h | palm fruit bunch |

| oil fractionation production line | 20–500t/d | refined palm oil |

| Oilseeds protein, phospholipids | 50–500t/d | soybean meal, etc. |

| grain deep processing line | 20–1000t/d | corn, wheat, beans, etc. |

Company Profile

Since 1982, our company was found officially registered under Henan Companies Registry. Who is the leader in the oil press equipment field of China. The main products are hydraulic oil press machine, screw oil press machine, the accessory equipment for the oil press machine and other equipments.Our company has a professional design R&D team and sales team, backed by the university and guided by the market to update the products, The products have covered the reigion of China with nearly a million users. Our products had exported to many countries such as United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Algeria, Bulgaria and so on, have received very good reputation.

Service

Pre-sales service1.Quick response2.Detailed quotation3.Professional production and transportation solutionAfter-sales service1.Warranty policy one year from shipment2. We will send you the replacement after received the broken part3. Evaluate the customs risk and choose safest shipping company before shipping.4. Follow status up time by time until the goods arrived.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.