Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Retail, Food Shop, Printing Shops, Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location:Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Chile, UAE, Algeria, Sri Lanka, Romania, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

Condition:New

Application:Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

Packaging Type:Cartons, Bags, Film

Packaging Material:Plastic, Paper

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220v/380v 50 hz

Place of Origin:Hebei, China

Brand Name:JIALONG

Dimension(L*W*H):2300*1400*2000 mm

Weight:5000 KG

Warranty:3 years

Key Selling Points:High Safety Level

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:3 years

Core Components:Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox, Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine

Name:Cangzhou Jialong fingerless single facer paperboard machine

Working speed:80 m/min

Heating type:oil , electric , steam

Description:fingerless single facer corrugated machine

Flute type:a,b,c,e,f ,s

Machine width:1600 mm

Function:Make two single layer to 2ply corrugated board

Product name:carton box making machine

Color:Customizable

Cangzhou Jialong Fingerless Single Facer Corrugados Paperboard Machine corrugados cardboard making machine for sale

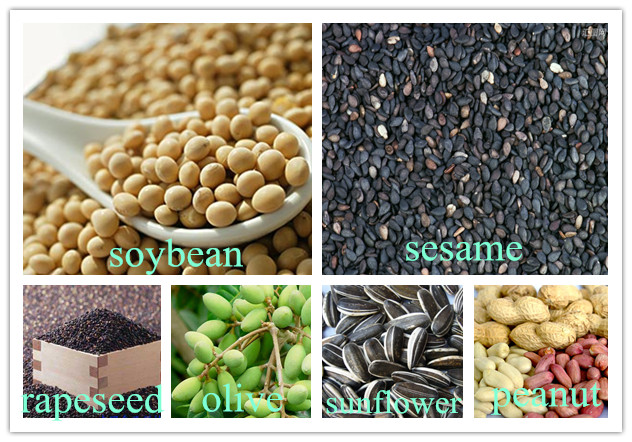

This oil press machine can be used to make cooking oil with raw materials such as flax seed, peanut, rapeseed, sesame,sunflower, etc.

Raw material

Processing materials: sunflower seed, peanut, mustard, almond, black sesame, tea seed, cottonseed, etc

Working priciple

Working priciple

Magnitic seperating:In order to remove the metal impurities, so that can prevent damaging the equipment and occuring safety accidents.Cleaning: To remove the imourities in the raw matrial such as soil, stem and leaf, hull and moldy seeds.Husking: In order to improve the oil yielding rate and the quality of crude oil and meal, reduce the wear to the equipment, the hull must be removed.Cooking: This processing can improve prepressing oil yielding rate and the quality of the cake, adjust the moisture, temperature and plasticity of the flake.Prepressing:To squeeze out part of the oil in the raw material, and improve extracting effect.

Advantage

1)Occupied workshop area is small.2)Special gear box structure make the rotating speed averagely.

Product Specification

Product Specification

| Item | 5TPD Peanut oil production line |

| Capacity | 5TPD |

| Power | 44kw |

| Installation size | Oil pressing line+oil refining line+oil filling line15m*2.5m*4.5m(L*W*H) |

Company Profile

Pre-Sales Service* Inquiry and consulting support. After-Sales Service* Training how to install and function the machine.* Engineers available to service machinery overseas.* 12 months warranty and life spand service available.* Flowchart and factory design. * View our Factory.

Service

We always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.