Showroom Location:None

Condition:New

Usage:Mulit

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:98%-100%

Place of Origin:Henan, China

Brand Name:PENGHUI

Voltage:220V/380V

Dimension(L*W*H):1700*1300*1600mm

Weight:780kg

Warranty:1 Year, One Year

Key Selling Points:Energy saving

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1.5 years

Core Components:Motor

Product name:Avocado Olive Cooking Oil Making Processing Machine Price

Raw material:Oil Seeds

Function:Oil Production

Advantage:Energy Saving

Application:Sunflower Coconut Palm Sesame Olive

Material:Food Grade Stainless Steel 304

Color:Customized

Item:Edible Oil Press

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Certification:ISO

Corn Groundnut Avocado Olive Cooking Oil Making Processing Machine Price

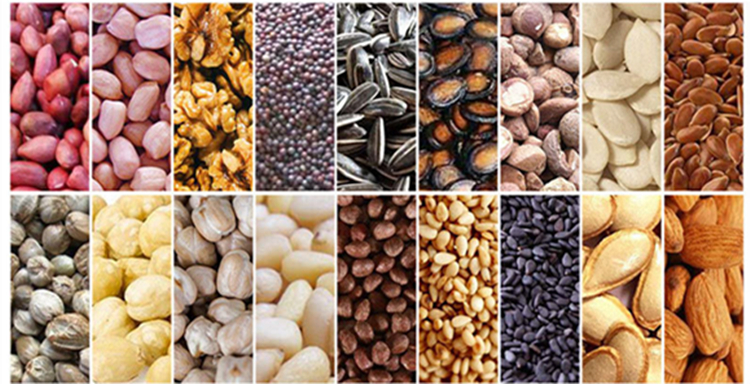

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Raw material

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more.

Working priciple

Working priciple

Palm oil is a tropical woody vegetable oil. It is the largest variety of vegetable oil in the world in terms of production, consumption and international trade. Because of the particularity of oil palm fruit structure, its oil-making technology and equipment are quite different from other oils. The oil-making process of palm oil mainly includes the following parts:sterilization and fermentation, threshing, mashing and cooking, pressing oil, crude oil purification, oil storage, separation of kernels and fibrous substances, separation of kernels and kernels, and storage of kernels.

Advantage

(1)The lubrication should be checked after every 50 hours of operation. The oil cup on the gearbox should not be short of oil. The screw shaft should be adjusted from the adjustment screw hole to the oil in the screw hole. Dry grinding is strictly prohibited.(2)The parts of the oil should be protected from dust and other impurities. The quality of the oil in the gearbox should be checked once a year. If it is found to be deteriorated, all oil should be replaced.(3) When the crushing amount is reduced and the cake or oil is not normal, the screw shaft should be taken out to check the wear of the screw, the strip and the cake ring, and the worn parts should be replaced in time.

Product Specification

Product Specification

| Model | TZ-60A | TZ-80A | TZ-100A | TZ-125A | TZ-150A |

| Screw diameter | 60mm | 80mm | 100mm | 125mm | 150mm |

| Capacity (kg/h) | 30-60 | 125-150 | 200-250 | 250-350 | 500-600 |

| Motor | 2.2kw | 5.5kw | 7.5kw | 15kw | 22kw |

| weight (kg) | 220 | 700 | 1100 | 1400 | 1700 |

|

Company Profile We have abundant experience in product research, strong technical force, sophisticated production, and specializing in production of oil press machine, the main products are automatic Hydraulic oil press, and related products: wok, vibrating screen, peanut sheller, sesame feeding machine, oil filter machine, spiral hoist, automatic seed feeding machine. Our hydraulic oil press is suitable for a variety of oil crops(sesame, peanut, walnut, mustard, olive, sunflower and more), all parts of the machine are made up of premium alloy steel and excellent craftsmanship, won an excellent reputation and satisfaction among customers.Welcome customers from worldwide come for a visit to our factory! Service Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development. FAQ Usually the delivery time is 3-15 working days after prepayment received.Q7: What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you |