Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Retail, Pharmaceutical industry

Showroom Location:United States, Pakistan, Colombia

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:5 years

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Condition:New

Application:Food, Commodity, Medical, Machinery & Hardware

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V/220V

Place of Origin:Zhejiang, China

Brand Name:LTPM CHINA

Dimension(L*W*H):1650*500*1100mm

Weight:650 KG, 650Kg

Warranty:5 years

Key Selling Points:Automatic

Blanking Frequency:15-40Punches/min

Sheet’s quantity of one blanking:1 sheets

Capacity:900-2100 sheets/hour

Adjustable scope of feed travel:10-110mm

Max. Forming:120*110*15mm

Power Supply:380V 50Hz 5.5Kw

Wrapper Specification(PVC):120*(0.15-0.5)mm

Wrapper Specification(PTP):120*(0.02*0.035) mm

Overall Dimensions:1650*500*1100mm

After Warranty Service:Video technical support, Online support, Spare parts

Local Service Location:United States, Brazil, Peru, Pakistan, Mexico, Argentina, Chile, Colombia

After-sales Service Provided:Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Certification:CE,ISO,GMP

DPP88 Edible Oil Blister Packing Chocolate Sauce Cream Syrup Honey Jelly Cup Food Blister Packaging Machine

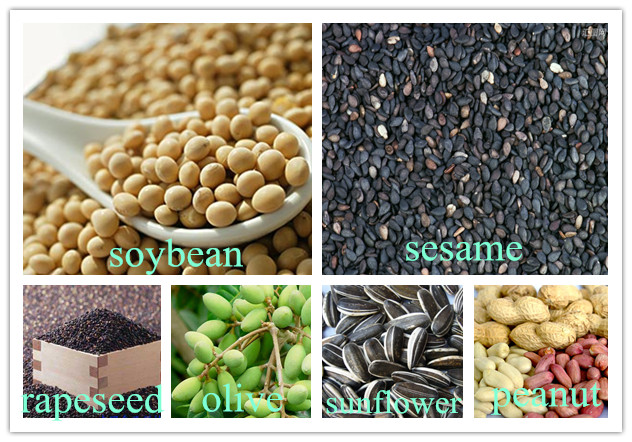

various raw materials, as ground nuts, bean, rape and cotton seeds, sesame, olive, sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

Raw material

Small business flaxseed sesame oil press groundnut processing oil machine is suitable with most raw materials, such as sesame, soybean, coconut, peanut, palm kernel, coffee bean, sunflower seeds, sea buckthorn seeds, moringa seeds, etc.

Working priciple

Working priciple

Screw expeller pressing is to separate the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of screw oil expeller, they have similar theories in screw expeller pressing.Because the screw type seed oil expeller is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process.

Advantage

6YL68 Screw Oil Press Machine characterized by its simple design, small volume and lightweight, easy to handle and move.This machine is able to extract oil from various of vegetable oil materials, the machine can be used for cold pressing as well as hot pressing, highly productive, easy for operating ,low labor intensity and high economical profit ,which also has less noise and a high rate of oil output, hence, it is welcome by customers.

Product Specification

Product Specification

| Model | Capacity | oil content in cake | Motor power(kw) |

| 202 | 40-50 TPD | less than 13% | 30 |

| 204 | 75-80TPD | 15-18% | 30 |

| LYZX24 | 20-25TPD | 10-19% | 30+5.5+3 |

| LYZX28 | 40-60TPD | 15-19% | 45+11+1.5 |

| LYZX32 | 80-100TPD | 15-19% | 90+.5+1.5 |

| LYZX34 | 150-180TPD | 11-15% | 160 |

| SYZX12 | 4-6TPD | 4-6.5% | 18.5+1.1 |

| SYZX24 | Hot pressing 80-100 TPD | 10-17% | 55+7.5 |

| Cold pressing 40-50 TPD | 5-7% |

Company Profile

We are located in Henan Province, China. Our annual production capacity of oil press machines and related machines is approximately 10,000 units. Our machines have been sold to many countries, such as Vietnam, Bangladesh, etc. Since 1982, we have continued to specialize in research to understand the needs of each country’s market and the best-selling models to provide the most suitable machines to help customers develop their businesses. Our oil press production line includes a variety of different series of machines, such as hot oil press, multi-function oil press, household oil press, oil filter, roaster, conveyor, etc. We have an experienced team, professional R&D and quality control system. These parts are manufactured by our own factory to ensure quality. Therefore, we eagerly hope to establish cooperative relations with domestic and foreign customers and bring you satisfactory products.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.