Commercial Buyer:Caterers & Canteens, Restaurants, Fast Food and Takeaway Food Services, Specialty Stores, Food & Beverage Manufacture, TV Shopping, Department Stores, Bubble tea,Juice & Smoothie Bars, Super Markets, Hotels, Convenience Stores, Spice and Extract Manufacturing, Drug Stores, Cafes and Coffee Shops, Discount Stores, E-commerce Stores, Gifts Stores, Beer,Wine,Liquor Stores, Souvenir Stores

Occasion:Business Gifts, Party, Wedding

Holiday:Valentine’s Day, Father’s Day, Eid holidays, Chinese New Year, Christmas, Thanksgiving

Room Space:Desktop, Countertop, Kitchen, Closet, Bathroom, Bedroom, Dining Room, Dorm Room, Entryway, Living Room, Kids Room, Office, Hallway, Laundry Room

Room Space Selection:Support

Occasion Selection:Support

Holiday Selection:Support

Air Freshener Use:Home, Atomization

Feature:Stocked

Place of Origin:Guangdong, China

Brand Name:OEM/ODM

Model Number:MX-605B

Active ingredient content:Above 80% (Inclusive)

Power Source:Electrical

Material:metal. black/white

Dimension:W155*H90*D240mm

Sound Volume:< 18dba

Installation:desktop or wall mountable

N.W:2.8 Kg

Diffuse coverage:900CBM/300㎡/31800Sq.ft

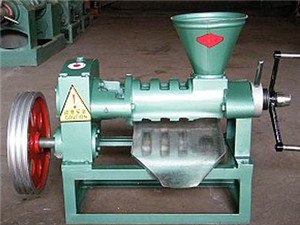

Power source:ElectricalOur machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Complete Edible Oil Manufacturing Unit includes♦ Cleaning process : Use vibration cleaning sieve and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc.♦ Crushing Process: This Process is mainly to crush the peanut , as the peanut is big ,it is not easy to press .We must crush the peanut to 6-8 pieces,then we need to peel .The rate of peel is about 90%.♦ Flaking Process : After crush and peel ,we need to flake the crushed sunflower , which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..♦ Cooking Process: After the flaker,we need to cook the flaked sunflower , control the moisture at 5-7% ,the temperature is 110-115degree.♦ Oil-pressing : After all the pretreatment , pre- press the sunflower , the oil can be extracted about 76% .♦ Primary Oil Filtering Process: after the oil pressing, the crude oil will be primary filtered and for store to tank or for next process of oil refinery.Centrifugalization is a kind of method using centrifugal force to separate suspended impurities. Through the drum high-speed rotation of the centrifugal force separate the impurities form oil to reach solid and liquid separation. When the drum stops rotating, and net oil flow from the drum to achieve the purpose of filtering . The filtered oil can do edible test , no foam, no overflowed.

Complete Edible Oil Manufacturing Unit includes♦ Cleaning process : Use vibration cleaning sieve and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc.♦ Crushing Process: This Process is mainly to crush the peanut , as the peanut is big ,it is not easy to press .We must crush the peanut to 6-8 pieces,then we need to peel .The rate of peel is about 90%.♦ Flaking Process : After crush and peel ,we need to flake the crushed sunflower , which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..♦ Cooking Process: After the flaker,we need to cook the flaked sunflower , control the moisture at 5-7% ,the temperature is 110-115degree.♦ Oil-pressing : After all the pretreatment , pre- press the sunflower , the oil can be extracted about 76% .♦ Primary Oil Filtering Process: after the oil pressing, the crude oil will be primary filtered and for store to tank or for next process of oil refinery.Centrifugalization is a kind of method using centrifugal force to separate suspended impurities. Through the drum high-speed rotation of the centrifugal force separate the impurities form oil to reach solid and liquid separation. When the drum stops rotating, and net oil flow from the drum to achieve the purpose of filtering . The filtered oil can do edible test , no foam, no overflowed.

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

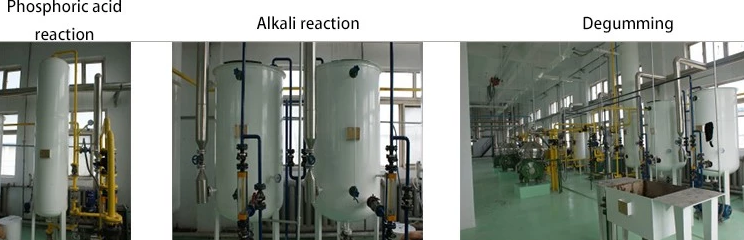

refining plant .adjustable, flexible operation, high automatic degree of sanitation.

Applicable oil: soybean oil, sunflower oil, rapeseed oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil, animal oil all need refining oil.

Refining plant capacity: 10-1000T / D

(1).Free training technological operator to ensure the trained staff can operation independently. (2).In the installation process,we will appoint a installation supervision staff on the spot(3).we will give you the English operate instrucation and the machine will equip with English name and conduct .(4).The warranty period is one year .In the warranty period, all because of the quality of products has caused the damage or failure of equipment, suppliers will take the responsibility for the free repair and replacing spare part. (5). We will priority to provide customer our new craftworks and products.Q1: What does Eternal need from me to quote a price?1.Raw material2.Production capacity per hourQ2: What is the oil yield?The oil yield depends on oil content of your material.If the oil content of your material is high,you can get more essential oil.The oil residual of our small hydraulic oil press machine, cold press virgin coconut/avocado/olive oil extraction extracting machine is 6%Q3: Can I use the machine to extract several kinds of raw materials?Yes,of course. such as sesame, sunflower seeds, soybean, peanut, coconut, etcQ4: Can I do extraction test with my own raw material?Yes,of course.We can do extraction test and send you videos and test report for your Reference.Q5: What is your material of your machine?