Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Food, Beverage, Chemical, oil

Packaging Type:Cartons, Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V/380V

Place of Origin:Shandong, China

Brand Name:tongda

Dimension(L*W*H):L1500*W1500*H1900mm

Weight:500 KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 6000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

Filling Material:Other, Milk, Water, Oil, Juice, paste liquid

Filling Accuracy:99.9%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, PLC, Gear, Bearing, Gearbox

filling heads:1/2/4/6/8/12/16

filling volume:50-20000ml

material:SS304/316

air pressure:0.5-0.7MPa

control:PLC+ Touch Screen

filling valves type:customed

filling type:Piston Cylinder

applicable bottle:pet and glass bottle

bottle diameter:30-150mm

warranty:12months

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE;ISO9001

factory linear 1/2/4/6/8/12/16heads high precision piston edible oil filling machine palm oil filling machine

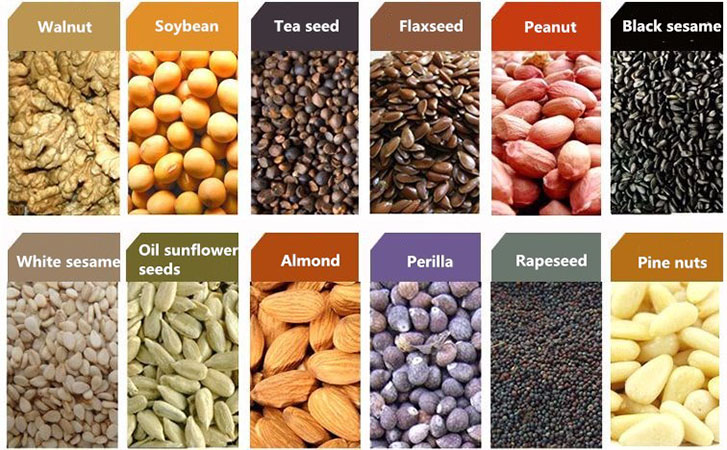

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

Raw material

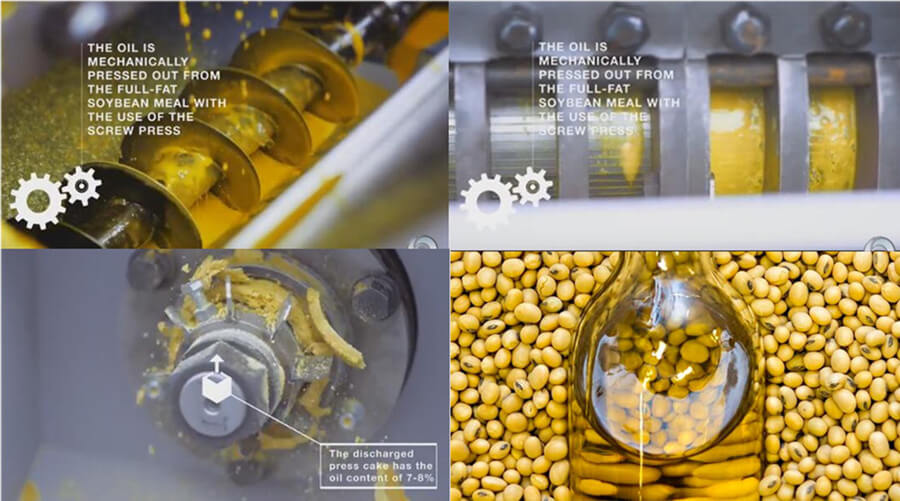

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Working priciple

Working priciple

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantage

Cast Iron Bodies and Base.Single Reduction Gear Box with Spur Gears.Fabricated chamber size : 20″ long x 3 1/2″ Diameter.Case hardened worm assembly.Superior quality of oil & cake.Chamber size 3.1/2″ x 20″ Long5 H.P. for expeller.Low Maintenance.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

Ensure the quality100% test before delivery All products undergo strict product quality testing before packing.Customized serviceWe are an industry and trade integrated company, has its own production workshop has its own research team. Provide personalizedcustomization service.Rich experienceMore than 30 years independent research and development, independent production experience. Excellent customer service andtechnical support.

FAQ

1. Q: Which kind of materials can be process?A: All kinds of oil seeds, including common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-5000 tons per day. 3.Q: How long is your guarantee ?A: One Year guarantee. Supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How is the quality of your products ?