Applicable Industries:Food & Beverage Factory, Farms

Showroom Location:None

Condition:New

Application:Food, Beverage, Chemical

Packaging Type:Cartons

Packaging Material:Wood

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V

Place of Origin:Shanghai, China

Brand Name:ALWELL

Warranty:1 Year, 12 Months/ One Year

Key Selling Points:Easy to Operate, High Productivity

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 20000BPH, 16000BPH

Filling Material:Beer, Milk, Water, Oil, Juice, Oil

Filling Accuracy:<1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Product name:Automatic Alcohol hand sanitizer liquid bottle filling machine

Usage:powder weighing filling machine

Function:liquid filling

Material:Stainless Steel 304 / 316L

Processing Types:Normal Pressure Filling

Filling range:2-100ml

Filling speed:30-60 Bottles/min

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Online support, Video technical support

Certification:CE

Factory Low Price Butter Filling Machine Peanut Butter Filling Package And Labeling Machine

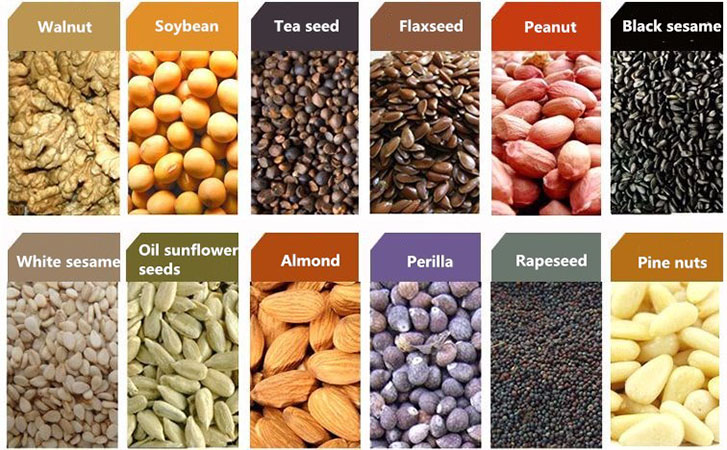

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Raw material

It can be used for various materials such as Peanuts, Rapeseeds, Sesame seeds, Soybeans, Cottonseeds, Tea seeds, Sunflower seeds, Palm kernel etc.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

1. Automatic screw oil press machine is suitable for most oil-bearing crops can realize thorough squeezing, continuous squeezed speed, high production efficiency, low energy consumption, high output.2.Automatic screw press machine is applicable to squeeze system various oil seed crops, mainly suitable for the squeeze sesame, peanut, rapeseed, sunflower, soybean oil crops , etc.

Product Specification

Product Specification

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

Company Profile

We are a professional manufacturer and exporter of mechanical equipment. Our products include edible oil process machines.Our well-equipped facilities,complete after-sale service system and excellent quality control system on all stages of production enable us to satisfy customers from different countries. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Service

1.We are a factory manufacturing edible oil machine, best production capability, best quality control, best Service.2.100% quality control inspection for every machine.3. Competitve price.

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.