Showroom Location:India

Condition:New

Usage:oil seeds

Type:Cold & Hot Pressing Machine

Automatic Grade:Manual

Production Capacity:100%

Place of Origin:Zhejiang, China

Brand Name:RAYONE

Voltage:220v

Dimension(L*W*H):1200*400*900mm

Weight:260 KG

Warranty:1 Year

Key Selling Points:Long Service Life

Marketing Type:Hot Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox, Other

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

Max Capacity:16-20 T/ 24hrs

Name:Oil Pressing Machine/Hydraulic oil press machine

Machine Material:Carbon Steel/ stainless steel

Function:Press Oil Seeds

Raw material:olive/peanut/coconut/palm/sunflower/soybean/hemp/avocado/mustar

Advantage:Energy Saving & Simple Operation

Package:Steel cage export

Delivery time:5-7 Days

After-sales Service Provided:Provide Longlife Technical Support, Video technical support, Online support

Machine color:white

Quality:High Level

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Local Service Location:India

Certification:CE/ISO9001

Factory Price Screw Palm Oil Press Machine coconut Oil Cold Press Extruder Machine Sunflower Oil Presser Manual Sales

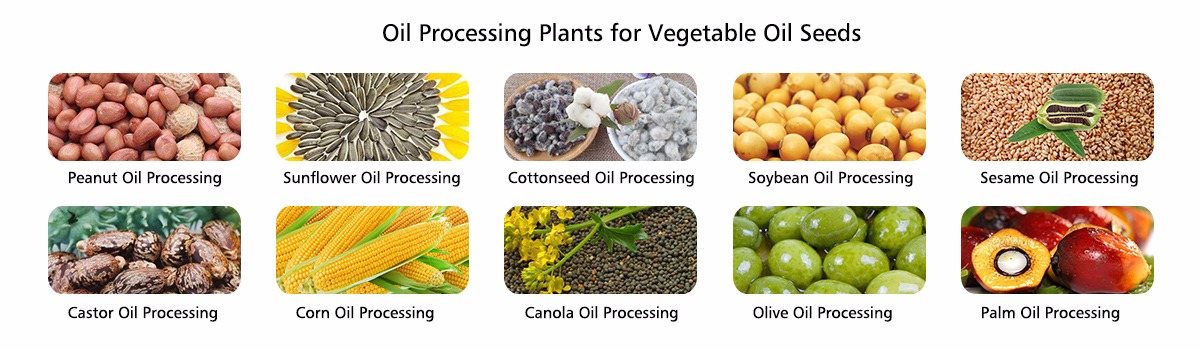

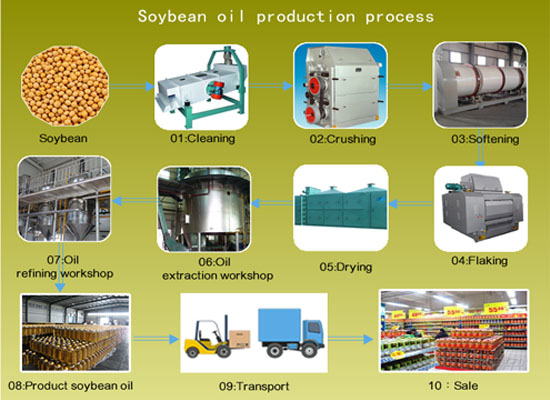

Vegetable oil making machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Working priciple

Working priciple

Cold pressing and hot pressing mode for oil press customer consultation:1. Cold pressing refers to the direct pressing of materials without stir-frying;2. Hot pressing means that the material is heated to 60-80 degrees and then put into pressing;3. No matter cold pressing or hot pressing, our oil press must preheat. Only when the press chamber is preheated to about 200 ℃ can the oil be separated from the material.If the machine is not heated, the material will only be extruded into a paste, and the grease cannot be separated.4. Under the cold pressing mode of the material, the normal temperature of oil coming out is about 40°, and the nutrients will not be lost. Under the material hot pressing mode, the oil yield will be higher, the oil will be more fragrant, the oil will come out at a temperature of 60-80 degrees, and some nutrients will be lost.5. Therefore, the hot pressing mode is generally suitable for pressing rapeseed, peanuts and other low-value edible oils, and the pursuit is oil yield and aroma of cooking;The cold pressing mode is generally suitable for pressing walnut oil, flaxseed, almond, olive kernel and other high nutritional auxiliary oil to ensure the nutrition is not lost.

Advantage

Cast Iron Bodies and Base.Single Reduction Gear Box with Spur Gears.Fabricated chamber size : 20″ long x 3 1/2″ Diameter.Case hardened worm assembly.Superior quality of oil & cake.Chamber size 3.1/2″ x 20″ Long5 H.P. for expeller.Low Maintenance.

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

Our company is a large-scale modern manufacturing company specialized in the R&D, manufacturing and sales of food oil processing machinery, which covers an area of 18,000 square meters. Numerous plants are installed in Netherlands, Kazakhstan, Malaysia, Nigeria, Nepal, Bangladesh, Sri Lanka, Indonesia, Bulgaria, New Zealand, Peru, South Africa, and Saudi Arabia, etc..We have our own showroom to showcase our products.You can meet all products there.Welcome to Company.

Service

1.Directly factory sell experience, knowing each mechanical progress;2.20 years experience during market of different kind of machines, Guarantee excellent machine quality for customer with Competitive price;3.More enough experience for international trade, Supply 24 hours service, on time solve any problem for customer;

FAQ

1. Q: Which kind of raw materials can be process?A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc from the pre-treatment,pressing,solvent extraction and refining plant.2. Q: What’s the production capacity can you process?A: 3-3000 tons per day. We can manufacture as customized order. 3.Q: How long is your guarantee ?A: One Year guarantee. We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred.4.Q: How about the quality of your products ?A : Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: We will send our engineers to local place to help installing the machine and provide technical guidance.6.Q: What’s the payment terms?A:T/T, Trade Assurance, L/C, Cash etc.