Applicable Industries:Food & Beverage Shops, cosmetic, pharmaceutical industry, beverage industry

Showroom Location:None

Condition:New

Application:Food, Beverage, Chemical, liquid, beverage, chemical, cosmetic, pharmaceutical industries

Packaging Type:Ply-wood case

Packaging Material:Wood

Automatic Grade:Semi-automatic

Driven Type:Pneumatic

Voltage:220V /50HZ or customized

Place of Origin:Jiangsu, China

Brand Name:Immay

Dimension(L*W*H):50*43*155cm

Weight:35 KG

Warranty:1 Year

Key Selling Points:High precision, easy operation

Machinery Capacity:1000BPH

Filling Material:Milk, Water, Oil, Juice, shampoo, cream, cosmetic cream

Filling Accuracy:>99.9%

Marketing Type:Hot Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, PLC

Product name:Semi-automatic filling machine

Usage:fill liquid or viscous cream

Processing Types:Automatic Bottle Filling Line

Filling speed:10-30 bottles/min./nozzle

Filling range:25ml to 5L customized

Filling nozzles:1-2 filling nozzles

Suitable bottle:cosmetic bottle filling,

Power supply:Pneumatic

Advantage:high precision and automatic filling

Factory provide high precision 1 nozzle pneumatic semi automatic mineral water peanut butter washing liquid filling machine

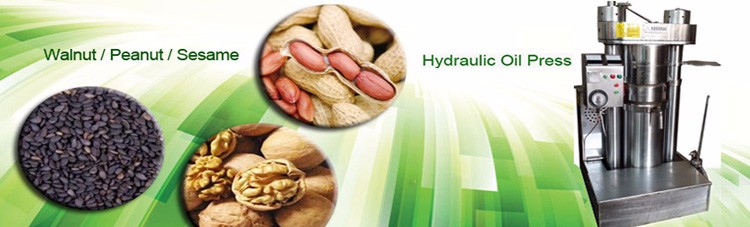

Processing materials: sunflower seed, peanut, mustard, almond, black sesame, tea seed, cottonseed, etc

Raw material

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more.

Working priciple

Working priciple

The Motor offers power to Hydraulic Box to squeeze the kinds of materials up and down in the kettle, through the Control System control the working pressure and temperature, stop working when the pressure over the set point(60mpa) automatically, when the pressure reduces to about 50mpa the machine will work again, this cyclic processing can squeeze materials roundly and improve the oil yield.

Advantage

1.High rate of oil yield: directional pressure,multi-step impelling,complete pressing once only.2.High output: strengthened feeding system,fast process,high efficiency.3.Automatic temperature control: electric program control,scientific heating, and automatic control of temperature.4.Automatic oil filtration: under the principle of negative pressure of air,vacuum diverter is adopted for effective separation of oil and residue.5.Safe and convenient: compact structure,small floor space;the transmission system adopts closed protection.6.Beautiful: the machine is coated with the latest material through static electricity,with strong adhesion and grease and high temperature resistance. It’s beautiful and easy to clean.7.Durable: High quality wear-resistant steel and anti-fatigue castings ensure stable performance and long-term continuous work.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

Since 1982, our company was found officially registered under Henan Companies Registry. Who is the leader in the oil press equipment field of China. The main products are hydraulic oil press machine, screw oil press machine, the accessory equipment for the oil press machine and other equipments.Our company has a professional design R&D team and sales team, backed by the university and guided by the market to update the products, The products have covered the reigion of China with nearly a million users. Our products had exported to many countries such as United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Algeria, Bulgaria and so on, have received very good reputation.

Service

Pre-sale services:Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment(1) Select equipment model;(2) Design and manufacture products according to clients’ special requirement;(3) Train technical personnel for clients.After-sale services:(1) Assist clients to prepare for first construction scheme;(2) Install and debug the equipment;(3) Examine the equipment regularly;(4)Take initiative to eliminate the troubles rapidly at site;(5)Provide technical exchanging;(6)Provide maintenance for big items

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.5.what kind of payment does your company support? T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.