Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Food & Beverage Shops

Showroom Location:Turkey, United Kingdom, Viet Nam, Brazil, Peru, Pakistan, Spain, Kenya, Chile, UAE, Colombia, Sri Lanka, Romania, South Africa, Ukraine, Nigeria, Malaysia

Condition:New

Application:Beverage, juice production machine

Packaging Type:Cartons, CANS, Bottles, Barrel, juice production machine

Packaging Material:Plastic, Metal, Glass, juice production machine

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380v ,can be made to order

Place of Origin:Jiangsu, China

Brand Name:JST

Dimension(L*W*H):3200X2200X2300mm

Weight:5000 KG

Warranty:2 years

Key Selling Points:Long Service Life

Machinery Capacity:8000BPH, 10000 BPH mango juice automatic beverage filling l

Filling Material:Beer, Milk, Water, Oil, Juice

Filling Accuracy:99.9%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, PLC, Engine, Siemens touch screen

Bottle size ::250ml-2000ml

Bottle material::PET or glass bottle

Cap type::HDPE or crown

Control::PLC+touch screen

Name::juice production machine

Label material::PVC

Packing type::PE film

Filling material::tea or juice

Machin material::SS304 / SS316L

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Turkey, United Kingdom, Viet Nam, Brazil, Peru, Saudi Arabia, Pakistan, Spain, Malaysia, Australia, Kenya, Argentina, Chile, Sri Lanka, Romania, Bangladesh, Ukraine, Nigeria

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE ,ISO

Fresh Fruit Apple Juice Filling Packing Production Line

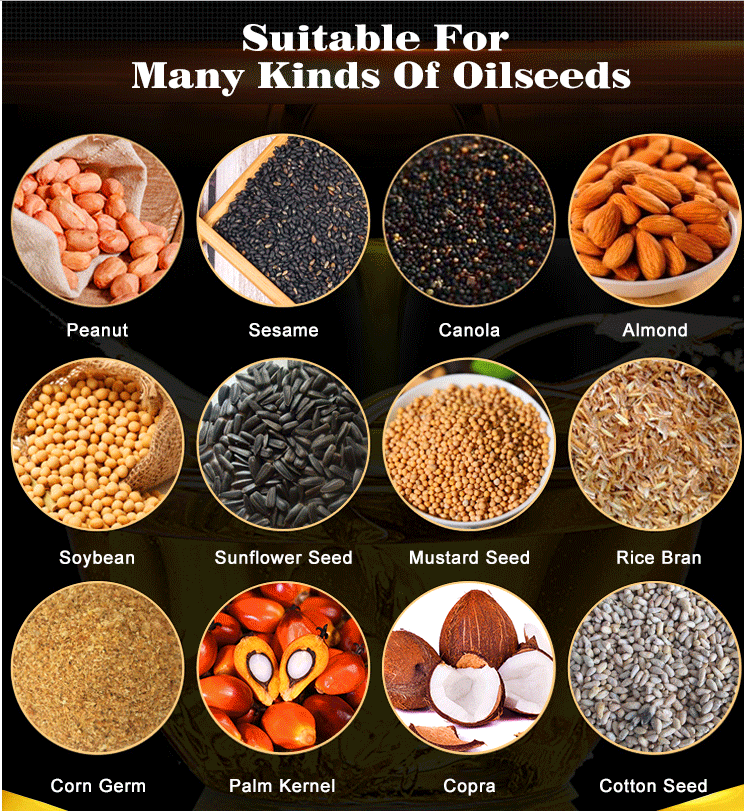

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Raw material

The oil production line is widely used in the production for various vegetable oils from the raw material to the final oil in the market. It is very popular for the production for edible oil and vegetable oils, such as sunflower oil, peanut oil, soybean oil,sesame oil, corn oil, palm oil, olive oil, castor oil, cottonseed oil, etc.

Working priciple

Working priciple

Main Parts Of The Automatic Oil Press Machine:1.screw shaft2.feeder3.pressing cage4.oil pan5.squeezing bolt6.vacuum oil filter system7.electric control system8.heating ring

Advantage

Advantages of cooking oil making machineThe whole extraction workshop is selected on the base of safety,reliable,energy-saving, less fault,easy maintenace,and long using life,adopting world advanced technology and equipment to achieve the beat process effects.Features of cooking oil processing machine:Applicable for various kinds of low oil content raw material,like rice bran, rapeseed, cotton, corn germ etc cakes for max oil yield. After extracting ,the resid oil is lower than 1%.

Product Specification

Product Specification

| Model | Capacity(kg/h) | Power(kw) | Machine Size(mm) | Weight(kg) |

| 6YL-80 | 100kg/h | 5.5kw | 1307x550x1102 | 350kg |

| 6YL-95 | 200kg/h | 7.5-11kw | 2155x580x1250 | 620kg |

| 6YL-100 | 200kg/h | 7.5-11kw | 2050x550x1180 | 520kg |

| 6YL-120 | 300kg/h | 11-15kw | 2150x610x1300 | 620kg |

| 6YL-125 | 350kg/h | 11—15kw | 1750x570x1320 | 620kg |

| 6YL-130 | 450kg/h | 15-18.5kw | 2180x610x1480 | 800kg |

| 6YL-160 | 550kg/h | 18.5-22kw | 2180x610x1480 | 1000kg |

| 6YL-165 | 700kg/h | 22-30kw | 2280x620x1680 | 1700kg |

Company Profile

Our company is a large-scale modern manufacturing company specialized in the R&D, manufacturing and sales of food oil processing machinery, which covers an area of 18,000 square meters. Numerous plants are installed in Netherlands, Kazakhstan, Malaysia, Nigeria, Nepal, Bangladesh, Sri Lanka, Indonesia, Bulgaria, New Zealand, Peru, South Africa, and Saudi Arabia, etc..We have our own showroom to showcase our products.You can meet all products there.Welcome to Company.

Service

1, 1 year free warranty. Whole lifetime maintenance.2, Supplying wearing parts all year around.3, Supporting technical solutions at any time.4, Helping design and plan the oil plant’s construction.5, Providing installation video.6, Tried orders are available.7, Developing agents with good policies around worldwide.Service before sale1.One-on-one exclusive customer service staff, 24 hours online.2.Inquiry, email, message will be replied at first time.3.Supply professional technical parameters, video picture sharing, project design.Service on sale1.Ensure customer payment security.2.Ensure the customer’s price is stable and reasonable.3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good. Service after sale1.Arrange high-efficiency delivery and safe transport.2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service.

FAQ

Q: How long is the smart oil press working once, how much material can be squeezed at one time?A: The working time is not limited.Q: Can the oil press be hot pressed and cold pressed? What is hot pressing? What is cold pressing?A: Yes. The hot press oil rate is higher than the cold press, but the nutritional value is not as healthy as cold pressed oil. Hot pressing is the fryed and heated material. The cold press is that the raw material is not heated before being put into the machine. The direct press of the oil press is cold pressing.Q: How much oil can the smart oil press press at one time? What is the oil yield?Answer: According to the material and operation mode, the different operation modes of different materials have different effects.Q: Can the oil press machine mixes and squeezes oil?A: Yes.Q: What kind of material is the squeezer made of? What material is the external ?A: The squeezed press bar is made of food grade 304 stainless steel, which has high strength and good wear resistance. It does not produce chemical reaction when pressed. The exterior is made of stainless steel, resistant to high temperatures, dirt and easy to clean.