Applicable Industries:Manufacturing Plant, Farms, Energy & Mining, Other

Showroom Location:None

Place of Origin:Henan, China

Brand Name:zhongming

Model Number:zm-8

Type:Refuse Collector

Warranty:1 Year

Power:25KW

Material:Wooden box, Carbon steel/stainless steel

Production Capacity:Other

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Marketing Type:New Product 2021

Warranty of core components:1 Year

Core Components:Other, Bearing, Gear, PLC, Pump

Weight (KG):40000 kg

Name /Type:Distillation machine

Application:Waste oil recycling

Product name:Fully Automatic Municipal Solid Waste Management

Raw material:waste oil

Function:Distillation

Final product:Gasoline, no standard diesel, base oil

Fuel:fuel oil/gas/electric

Color:Client’s Requirements

Application field:Resource Recycling Industry

fuel oil distillation line decolorization plant diesel refining system

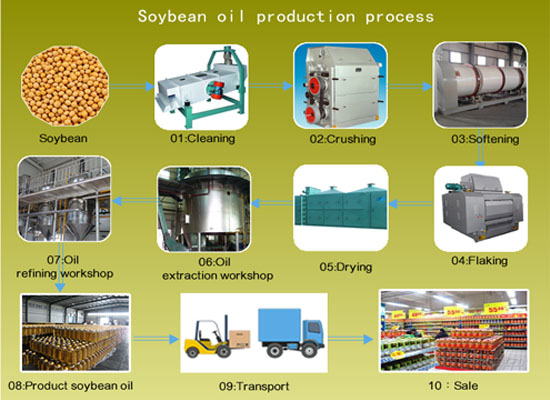

Our Integrated oil press is used widely for processing rapeseeds, cottons, soybeans, peanuts, sesames, sunflowers, tung seeds, olive coconut meat,palm and other granulated oil materials, as well as using for rice bran, corn embryo and powered oil materials and safflower and other wild plant oil materials. It’s regeneration products for medium-small scale plant oil mill in country and private factory,and ideal choice for users to realize well-off life.

Raw material

Our screw type oil press machine is multifunctional, which can be applied to many kinds of common oil crops such as the ricino, coconut, almond, hemp seeds, canola,walnut, copra, palm kernels, rapeseed, coconut, cotton seeds, sesame, Neem, boaba, soybeans, flaxseed, peanuts, sunflower seeds etc.

Working priciple

Working priciple

Oil solvent extraction section of vegetable oil production line:Cooking oil solvent extraction machine mainly include oil extraction system, desolventizing and toasting system, evaporation system and condensation system. Main theory is to use appropriate solvent extract oil from oilseeds embryo, then remove the solvent in mixed oil. Our oil extraction process technology to produce mixed oil without any chemical solvents, and can remove the tail gas directly, benefits environment protection.

Advantage

(4)After the end of each shift, the residual cake in the machine should be removed and the dust and grease on the surface of the machine should be wiped clean.(5) When storing for a long time after the end of the production season, maintenance should be carried out once, and the snails, the squeezed strips, the cake strips should be removed and washed and re-applied, and placed in a dry place.

Product Specification

Product Specification

| Model | 6JY-60 | 6JY-70 | 6JY-80 | 6JY-100 | 6JY-125 | 6JY-150 |

| Squeeze spiral Diameter | 55mm | 63mm | 80mm | 100mm | 125mm | 150mm |

| Squeeze screw speed | 64r/min | 63r/min | 63r/min | 43rmin | 36rmin | 36r/min |

| Power | 2.2kw | 3kw | 5.5kw | 7.5kw | 11kw | 15kw |

| Heating power | 0.9kw | 1.5kw | 3kw | 3.5kw | 4kw | 4kw |

| Capacity | 30-60kg/h | 60-90kg/h | 80-130kg/h | 200-260kg/h | 300-350kg/h | 450-500kg/h |

| weight | 230kg | 280kg | 565kg | 760kg | 920kg | 1200kg |

| size(LWH) | 1200*800*1160 | 1400*950*1250 | 1650*1500*1600 | 2000*1500*1720 | 2100*1500*1750 | 1600*2100*1720 |

| Voltage | 220v | 220v | 380v | 380v | 380v | 380v |

| Model | Capacity(t)/Day | Power(KW) | Material | Loading size(container) | Process range |

| YHJ-03 | 1.8T | 30.95KW | SUS304/316 | 20GP | 1-4 Grade |

| YHJ-05 | 3T | 37.45KW | SUS304/316 | 20GP | 1-4 Grade |

| YHJ-10 | 6T | 46KW | SUS304/316 | 40HQ | 1-4 Grade |

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We offer many different products to cater to different markets all-over the world and to offer a more customized experience and services to individual customers.we own a complete production line for brick machines only as well as block machines. By having great business relationships with location companies, we have ensured a steady supply of materials,which makes short wait times and excellent customer purchasing experience. This makes customers a worry free, “one-stop”shopping location for our customers.

Service

Service before sale1.24 hours online.Your inquiry will be quickly replied by email.Also all questions with you can be sloved by any online chatting tools.2.Professionally and patiently introduction, details pictures and working video to show machine.Service on sale1.Installation:quality and quantity guaranteed;completion of hand over.2.Acceptance: acceptance test;accepted deliverables.3.Technical tranining:on-site installation and products training.Service after sale1.Technical service:long time technical service.2.Accessories supplying:supplying spare parts with cost price.3.Client review:call-back;regular return visit.4.24 hours online to solve any problem .

FAQ

Q1:WHY BUY FROM US?1) As a real manufacturer, we can supply the best quality machines with reasonable price.2) All the machines pictures and features are real, captured by us, NO Cheating, NO Fraud.3) We are able to get the exactly products for you since we know these machines very well4) We can supply the parts and service in long future.Q2: ARE YOU A NEW MANUFACTURER?A2:We are a major oil press manufacture with a long history in China, in the past decades, we’re focused on domestic market and exporters. Q3: DO YOU HAVE OTHER PRODUCTS ?A3: Yes, we do have a lot of products over than this sit, please feel free to ask us any questions about our products.