Warranty:1.5 years

Applicable Industries:Manufacturing Plant, Machinery Repair Shops, Energy & Mining

Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1.5 years

Core Components:Gearbox, Pressure vessel, Pump, Gear, Bearing, Engine, Motor, PLC

Condition:New

Type:Oilfield Centrifuge

Model Number:LW450*1200D

Place of Origin:Sichuan, China

Product Name:decanter centrifuge

Drum Size (mm):450*1200

Drum Rate Speed rpm):2200

Max Capacity (m3/h):40

Main Motor (kw):37

Differential Speed Ratio:57:1

Dimension (mm):2900*1820*1820

Weight (kg):3300

Max G-Force:1218

Country of origin:China

GAMBOSS Reliable Performance Oil Well Drilling Mud Decanter Centrifuge Separator of Solid Control Equipment

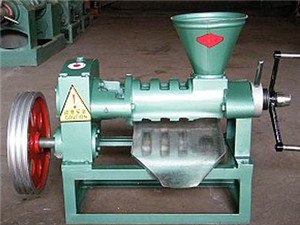

rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Working priciple

Working priciple

The flow chart process of palm oil processing machinePalm fruit bunches–Sterilizing–Threshing–Digesting–Pressing–Clarifying–Filtering–Drying–Crude palm oil.

Advantage

1.High rate of oil yield: directional pressure,multi-step impelling,complete pressing once only.2.High output: strengthened feeding system,fast process,high efficiency.3.Automatic temperature control: electric program control,scientific heating, and automatic control of temperature.4.Automatic oil filtration: under the principle of negative pressure of air,vacuum diverter is adopted for effective separation of oil and residue.5.Safe and convenient: compact structure,small floor space;the transmission system adopts closed protection.6.Beautiful: the machine is coated with the latest material through static electricity,with strong adhesion and grease and high temperature resistance. It’s beautiful and easy to clean.7.Durable: High quality wear-resistant steel and anti-fatigue castings ensure stable performance and long-term continuous work.

Product Specification

Product Specification

| model | Capacity (kg/h) |

Voltage (V) |

Vacuum power | Power (kw) |

Squeeze speed | Weight (kg) |

Dimension (mm) |

| 6YL-70 | hot:60kg | 380v | 0.75kw | 4kw | 600-100BRM | 440kg | 1400*1000*1500 |

| 6YL-85 | 100kg | 380v | 1.1kw | 11kw | 600-100BRM | 550kg | 1600*1100*1600 |

| 6YL-100 | cold:75kg hot:180kg | 380v | 1.1kw | 11kw | 600-100BRM | 1200kg | 2100*1500*1800 |

| 6YL-108 | 200kg | 380v | 1.1kw | 11kw | 600-100BRM | 1400kg | 2200*1500*1800 |

| 6YL-118 | 230kg | 380v | 1.1kw | 11kw | 600-100BRM | 1500kg | 2300*1500*1800 |

| 6YL-128 | cold:150kg hot:300kg | 380v | 1.1kw | 15kw | 600-100BRM | 1750kg | 2500*1500*1800 |

Company Profile

Our Company supply the complete set of Cooking oilproduction line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, corn germ oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, moringa seeds oil production line and other vegetables oil processing machines.

Service

Pre-sale services1) Selecting equipment type;2) Designing and fabricating the products in accordance with the special requirements of the clients;3) Training technical personnel for our clients;4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.After-sale services1) Assisting the clients preparing for the first construction scheme;2) Installing and testing the equipment;3) Training the first-line operators on site;4)Supplying spare parts with cost.

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.