Applicable Industries:Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Food & Beverage Shops

Showroom Location:Indonesia

Condition:New

Application:Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Tobacco

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V 50-60HZ

Place of Origin:Jiangsu, China

Brand Name:Jerry pack

Dimension(L*W*H):2200*1300*2200

Weight:800 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:4000BPH, 2000BPH, 1000BPH

Filling Material:Beer, Milk, Water, Oil, Juice, Other

Filling Accuracy:±0.5%

Marketing Type:Hot Product 2019

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, PLC

Product name:Piston Filling Machine

Function:Automatic Filler

Filling volume:50ml-1000ml

High Quality Automatic Explosion-Proof 75% Alcohol Gel Hand Sanitizer Bottle Liquid Filling Capping Labeling Line Machine

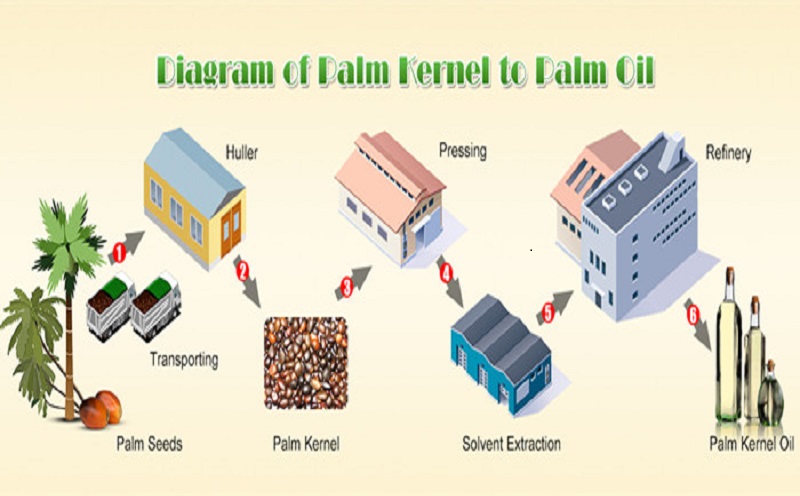

All kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

Our Integrated oil press is used widely for processing rapeseeds, cottons, soybeans, peanuts, sesames, sunflowers, tung seeds, olive coconut meat,palm and other granulated oil materials, as well as using for rice bran, corn embryo and powered oil materials and safflower and other wild plant oil materials. It’s regeneration products for medium-small scale plant oil mill in country and private factory,and ideal choice for users to realize well-off life.

Working priciple

Working priciple

Crude seeds→ cleaning → softening → expanding → drying → to extraction workshop; Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect.

Advantage

1.304/316 SUS 2.Customized crude oil refining line capacity. We customize plant as per your requirement for the capacity.3. Flexible usage. The crude oil refining line can work independently or together with whole oil production line.4. Two sets centrifugal machine make sure all continuous production , degumming result is very good.5.The refined oil has high quality and is good for long time storage.6. Oil can reach national standard(LEVEL 2), it can be sold in supermarket.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

Our company have different machine suitable for all kinds of oil seeds, eg: sunflower seed, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Service

Before-sale services:(1)Guide customers to choose the best appliable machine type; provide the advanced, energy -saving and practical technological process.(2) We are responsible for the process chart and design.Sale services:(1)Products must be inspected strictly before selling;(2)In accordance with the agreements stipulated in the contract.(3)We will organize delivery.After-sale services:(1)Our company will send professional engineers to guide with device installation, debugging and training operators until customers are fully satisfied. Moreover, we will design and manufacture products, according to the special requirements of customers.(2)The quality guarantee period for machines is one year except the wearing parts.

FAQ

1. Q: Are you a trading company or a manufacturer ? A: We are a manufacturer, which has long experience in this industry. 2. Q: How can I get to your company ? A: You can get a flight to Xinzheng Airport. We are just about 40- 50mins away from Xinzheng Airport. 3. Q: How long is your guarantee ? A: One year(Calculated from the equipment arrives the customer’s side.). After this period we will definitely support you when needed. You will be welcome to contact us with any problem may happened. 4. Q: Will you send engineers to install the plant?A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.5. Q: Do you have some foreign customers using your equipment?A: yes, we have our company has established business relationships with customers in Russia, German, Slovakia, Ukraine, Vietnam, Pakistan, the Philippines, Indonesia, Thailand, Pakistan, Egypt ,Iraq, Jordan, Saudi Arabia, Syria, Libya etc.