Place of Origin:Sichuan, China

Brand Name:none

Model Number:BS

Material::Polyurethane

Product name:BS

Color:Green

Temperature:-35°C~ +120°C

Speed::≤0.5m/s

Application::Hydraulic and cylinder

MOQ::10PCS

Medium::Hydraulic oil, gas, water

Payment::L/C.T/TWestern Union

Shippment::By Air By Sea. DHLFedex, UP…

High quality polyurethane BS type double lip piston rod oil seal for hydraulic cylinder

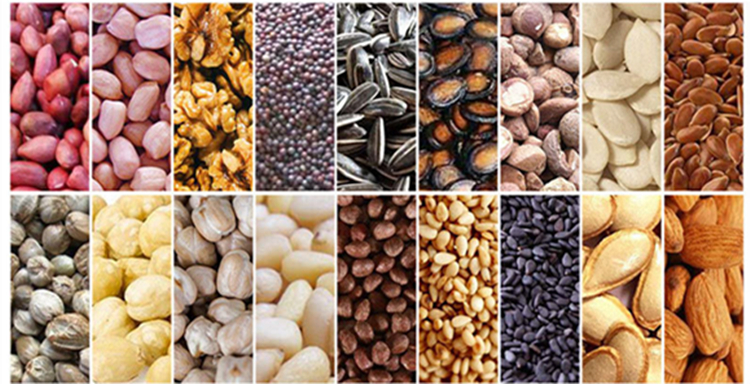

Although 6YL-68 Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Raw material

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

(1) High oil yield , obvious economic benefit.(2)Residual oil rate in the dry meal is low.(3)Improving the quality of the meal and oil.(4)Low processing cost , high labor productivity.(5)High automatic and labor saving.And more other advantages please contact me now,we will provide profession program for you,and we accept custom according your requirements.

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

Our company After 30 years development, now our company becomes an independent economic entity with the integration of science, engineering and trading department. our products and are widely accepted in both domestic and now open the world market, service to more than 100 countries, such as England, Russia, Sweden, Poland, Iran, Sudan, South Malaysia, Indonesia, Vietnam, etc.

Service

Pre-saleSystem evaluation: Project basic situactionSolution: The investment budget ,Technical discussionProduct selection: Factory inspection,Technical discussion Supply professional drawing and listsWin-win cooperation: Sign the contract,Wstablish mutual benefit In-saleDesign evaluation: Detailed technical assessment, Design of process and equipment layoutProcurement: Strictly inspection,optimized selection.Installation: Quality and quantity guaranteed,Completion of hand overAcceptance: Acceptance test , Accepted deliverables After-saleTechnical service: Long time technical serviceAccessories supplying: Supplying spare parts with costComplaint handling: 12-24 hours response mechanismClient Review: Call-back , Regular return visit.

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.