Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location:None

Place of Origin:Shandong, China

Brand Name:YIMEI

Material:plywod case

Weight:55kgs

Size:0.65*0.73*0.84m

Power:45w

Warranty:1 Year

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Canada, United States, Viet Nam, Philippines, Peru, Indonesia, Mexico, Russia, Malaysia, Kenya, Argentina, Sri Lanka, Kazakhstan, Kyrgyzstan

After-sales Service Provided:Video technical support, Field installation, commissioning and training, Free spare parts, Online support

absorb oil capacity:75L/h

application scope:Machinery manufacturing, steel, petroleum, chemical industry cooling

belt material:Special hydrophobic stainless steel

belt width:100mm

belt thickness:0.3mm

industrial belt oil skimmer

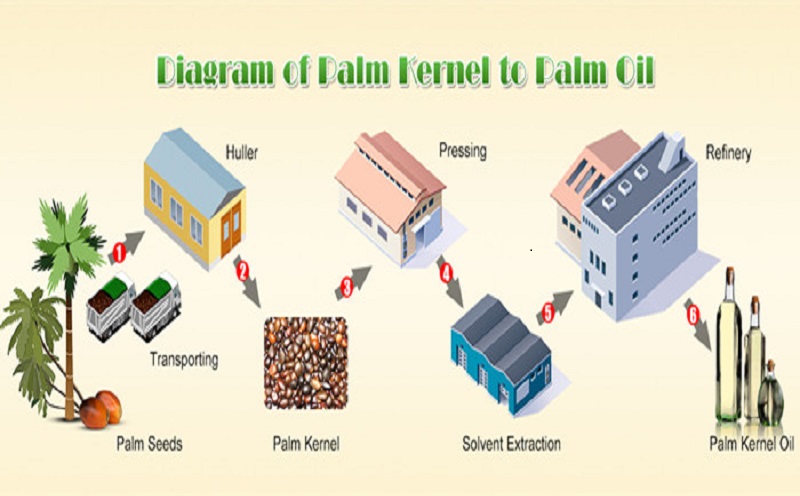

Vegetable oil making machine is suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Working priciple

Working priciple

Main Process of cooking oil refinery machine:1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.3. Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Advantage

Green health & Energy saving & Save labor and long life & High oil recoveryWidely used & Small footprint & Quick cost recovery

Product Specification

Product Specification

| Model | Capacity | Power | Electric machinery | Packing size(mm) | Gross andnetweight(kg) |

| 6YL-80oil press machine | 80-150Kg/h | 5.5KW | 380V/50HZ/Triple phase | 1510*440*700 | 350/330 |

| 6YL-95/100oil press machine | 150-200Kg/h | 7.5KW | 380V/50HZ/Triple phase | 1910*550*765 | 450/420 |

| 6YL-120oil press machine | 200-300Kg/h | 11KW | 380V/50HZ/Triple phase | 2100*630*770 | 530/500 |

| 6YL-130oil press machine | 300-400Kg/h | 15KW | 380V/50HZ/Triple phase | 2280*700*780 | 780/750 |

| 6YL-160oil press machine | 400-600Kg/h | 18.5KW | 380V/50HZ/Triple phase | 2050*600*850 | 950/900 |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

Service before sale:1.24 hours online .Your inquiry will be quick reply by email .Also can go through all questions with you by any online chatting tools ( Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )2.Professionally and patiently introduction, details pictures and working video to show machine.Service on sale :1.Test every machine and inspect the machine seriously .2.Send the machine picture which you order , then packing it with standard export wooden Box after you confirm the machine is ok .3.Delivery: If deliver it by sea . After delivering it to seaport . We will tell you the shipping time and arrival time. Finally, send all original documents to you by Express For Free.If deliver it by express to you( DHL, TNT, Fedex, etc), we will tell you the tracking number after delivering.Service after sale :1.Free insurance for goods.2.24 hours online to solve any problem . Supply you English manual book and technical support,maintain and install video to help you solve the problem, or dispatch worker to your factory.

FAQ

1. Q: Are you a trading company or a manufacturer ? A: We are a manufacturer, which has long experience in this industry. 2. Q: How can I get to your company ? A: You can get a flight to Xinzheng Airport. We are just about 40- 50mins away from Xinzheng Airport. 3. Q: How long is your guarantee ? A: One year(Calculated from the equipment arrives the customer’s side.). After this period we will definitely support you when needed. You will be welcome to contact us with any problem may happened. 4. Q: Will you send engineers to install the plant?A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.5. Q: Do you have some foreign customers using your equipment?A: yes, we have our company has established business relationships with customers in Russia, German, Slovakia, Ukraine, Vietnam, Pakistan, the Philippines, Indonesia, Thailand, Pakistan, Egypt ,Iraq, Jordan, Saudi Arabia, Syria, Libya etc.