Applicable Industries:Manufacturing Plant, Food & Beverage Factory

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Chemical

Packaging Type:Bags, Pouch

Packaging Material:Plastic

Automatic Grade:Automatic

Driven Type:Electric

Voltage:110/220

Place of Origin:China

Dimension(L*W*H):360*360*220mm

Weight:8.5 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:168LH

Filling Material:Beer, Milk, Water, Oil, Juice, Powder, Other

Marketing Type:Ordinary Product

Machinery Test Report:Not Available

Video outgoing-inspection:Not Available

Warranty of core components:1 Year

Core Components:Motor, PLC

After Warranty Service:Online support

Lh-852 Honey filling machine 17L/min Large Flow Liquid Filler for Vegetable Oil, Yogurt, Detergent, Shampoo, Honey, Wood Glue

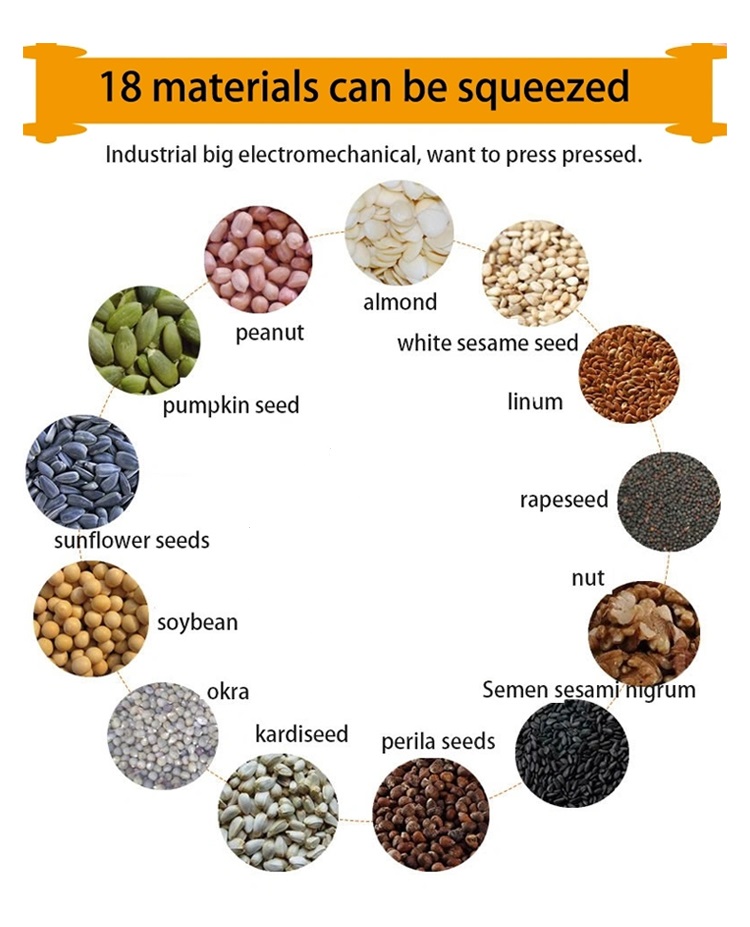

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Raw material

rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

* Occupied workshop area is small.* Special gear box structure make the rotating speed averagely

Product Specification

Product Specification

| Processing capacity | 3.5T–11T Per day. |

| Residue oil of the cake | ≤7.8% |

| Temperature control power | 3.0kw |

| Main electromotor power | 11kw |

| Spiral axes rotate speed | 32-40 |

| Weight | 1000kg-1400kg |

Company Profile

We are a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.

Service

Acceptance standardUnless stipulated in the technical documents accordingly, technology acceptance standards of designed main parts are in accordance with relevant state departments issued current relevant standards. providing main parts technology acceptance standard of technical design. Technical serviceDuring rice mill machinery installation, We cooperate with buyer for technological improvement to reach desired results. We explains rice mill machinery performance, structure and operation to buyer related people for free.Quality guaranteed We makes sure our rice mill machinery achieve promised performance with correct installation, commissioning, normal operation and maintenance. In warranty period, for quality problem, we repair and replace defective parts for free(except quick-wear part).

FAQ

Chrome steel or Stainless steelQ6: How long does it take to produce the machine once I place my order ?