Showroom Location:United States

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:New Product 2020

Warranty of core components:1 Year

Core Components:Pump, PID

Condition:New

Power Source:Electric

Process:Vacuum Distillation

Place of Origin:Shanghai, China

Brand Name:Linbel

Voltage:ustomized made

Power:1100W

Weight:40 KG

Warranty:1 Year

Key Selling Points:Automatic

Product name:Molecular Distillation

Rotary flask:5L

Rotating Speed:50-1800 r/min

Collection flask:5L

Motor power(W):1100W

Function:Extract Essential Oil

Usage:Disillation

Temperature range( c ):RT-380C

After Warranty Service:Video technical support

After-sales Service Provided:Free spare parts

Linbel Short Path Distillation 5l Short Path Distillation Kit

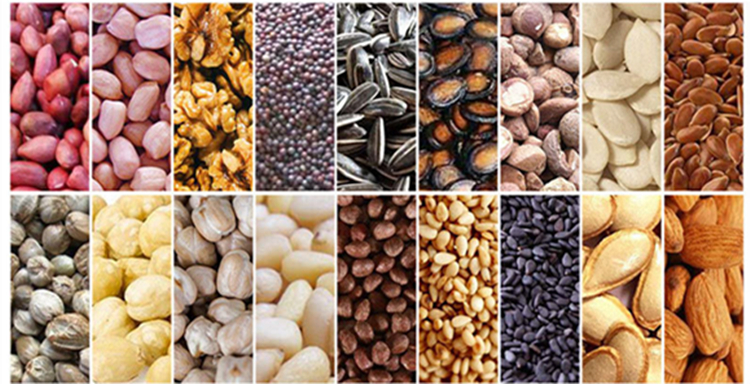

Raw amterials: Such as copra, cottonseeds, soybean, rapeseeds, peanut, sunflower seeds, tea seeds, olive,etc.

Raw material

Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm seeds and jatropha seeds.

Working priciple

Working priciple

1.Advantage: nice shape, highly structured, easy installation, , fast warn-up and high oil output rate 2.New type:this kind of machine is our latest environment protection oil press.3.Main feature:this kind of combined oil press machine mainly has 3 parts: electric control box to control the machine working, oil pressing part, and vacuum filtering part for clearing oil.4.Function: hot press and cold press are available.5.Structure:6YL-B series integrated oil press machines are designed on the basis of the advantage of 6YL-series oil press6.Suitable place:this kind of machine is situable for small-medium factory and supermarket.

Advantage

1, to reduce wear and tear on the follow-up equipment, improve environmental quality workshop;2, improve equipment production, improve oil yield, to ensure maximum quality fat, meal and byproducts;3, the lowest rate of fuel crushing, destructive for protein meals minimum.

Product Specification

Product Specification

| Project name | capacity | suitable for raw material |

| oil pressing production line | 10–800t/d | sunflower seed, soybean, peanut, sesame, corn germ, tea seed, rapeseed, cottonseed, etc |

| oil solvent-extracting production line | 30–800t/d | pressed oil cake, soybean flakes, rice bran pallet, etc. |

| oil refining production line | 3–500t/d | all kinds of vegetable oil |

| palm oil mill production line | 5t/h–90t/h | palm fruit bunch |

| oil fractionation production line | 20–500t/d | refined palm oil |

| Oilseeds protein, phospholipids | 50–500t/d | soybean meal, etc. |

| grain deep processing line | 20–1000t/d | corn, wheat, beans, etc. |

Company Profile

Our company is a large-scale modern manufacturing company specialized in the R&D, manufacturing and sales of food oil processing machinery, which covers an area of 18,000 square meters. Numerous plants are installed in Netherlands, Kazakhstan, Malaysia, Nigeria, Nepal, Bangladesh, Sri Lanka, Indonesia, Bulgaria, New Zealand, Peru, South Africa, and Saudi Arabia, etc..We have our own showroom to showcase our products.You can meet all products there.Welcome to Company.

Service

Acceptance standardUnless stipulated in the technical documents accordingly, technology acceptance standards of designed main parts are in accordance with relevant state departments issued current relevant standards. providing main parts technology acceptance standard of technical design. Technical serviceDuring rice mill machinery installation, We cooperate with buyer for technological improvement to reach desired results. We explains rice mill machinery performance, structure and operation to buyer related people for free.Quality guaranteed We makes sure our rice mill machinery achieve promised performance with correct installation, commissioning, normal operation and maintenance. In warranty period, for quality problem, we repair and replace defective parts for free(except quick-wear part).

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.