Showroom Location:None

Condition:New

Usage:SUNFLOWER OIL

Type:Cold & Hot Pressing Machine

Automatic Grade:Manual

Production Capacity:98%-100%

Place of Origin:Shandong, China

Brand Name:Daohang

Voltage:220v

Dimension(L*W*H):500*300*700mm

Weight:70 KG

Warranty:1 Year, 1 year

Key Selling Points:Multifunctional

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Not Available

Warranty of core components:1 Year

Core Components:Cylinder

Oil type:Flax Seed Oil, Rap seed oil, SESAME OIL, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL

Max Capacity:0.75 kg/batch

Product name:DH-32TB Mini Manual Hydraulic Cold Sunflower Seed Oil Press

Raw material:Sunflower seed, Avocado, Coconut, etc

Color:Red

Material:Stainless Steel 304

Capacity:2-4kg/h

Chamber Depth:180mm

Chamber Diameter:100mm

Advantage:Simple Operation, long service life

Delivery Time:7 days after payment

Mini Manual Hydraulic Cold Sunflower Seed Oil Press

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Raw material

The Oil press is used to get the edible oil or bio-diesel from vegetable oilseed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, seasame seed, cottonseed, coconut,, etc

Working priciple

Working priciple

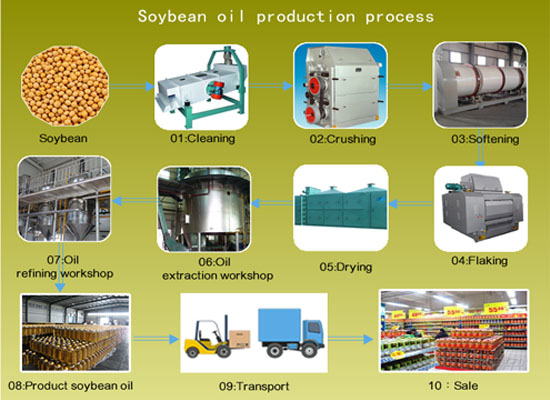

Brief processes:Fresh Solvent–Cake–Extracting–Wet Meal–Desolventising–Meal–Miscella–Evaporating and stripping–Solvent mixture–Condensing and Recovering–Crude Oil–Solvent Recycling–Refining Workshop.

Advantage

* Cast iron machine base* Special gear box structure make the rotating speed averagely* High Manganese steel* vegetable oil seeds, soybeans, peanuts, cotton seeds, sesame seeds, palm kernel, coconut etc* Compact structure, stable function, simple maintenance

Product Specification

Product Specification

| Processing capacity | 3.5T–11T Per day. |

| Residue oil of the cake | ≤7.8% |

| Temperature control power | 3.0kw |

| Main electromotor power | 11kw |

| Spiral axes rotate speed | 32-40 |

| Weight | 1000kg-1400kg |

Company Profile

We are a comprehensive enterprise integrating R&D, production and sales. The existing standardized production workshop covers an area of 5,000 square meters, and it has established a mechanical equipment exhibition hall of 2,000 square meters.The company has always been market demand-oriented. The company has a complete design, production, sales and perfect after-sales service system to provide you with high-efficiency, energy-saving and environmentally friendly mechanical products and processes. The company has a research and development department that can provide you with customized services in addition to standard products.The company relies on scientific management system, high-quality products, good sales and full-process technical services, and has been widely praised by customers. The needs of customers are our way forward, and we look forward to cooperating with you!

Service

Ensure the quality100% test before delivery All products undergo strict product quality testing before packing.Customized serviceWe are an industry and trade integrated company, has its own production workshop has its own research team. Provide personalizedcustomization service.Rich experienceMore than 30 years independent research and development, independent production experience. Excellent customer service andtechnical support.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.