Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Other

Showroom Location:None

Condition:New

Application:Food, Commodity, Chemical, Other

Packaging Type:Strong Wooden Case

Packaging Material:Wood

Automatic Grade:Automatic

Driven Type:Pneumatic

Voltage:220/380V 50/60Hz

Place of Origin:Tianjin, China

Brand Name:MTW

Dimension(L*W*H):2400*900*2200mm

Weight:500 KG

Warranty:1 Year

Key Selling Points:High Productivity

Machinery Capacity:Other, 2000-4500BPH

Filling Material:Other, Oil, cosmetic/chemical products

Filling Accuracy:+/-0.5~1%

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:2 years

Core Components:Motor, Pressure vessel, Pump, Other, PLC, Gear, Bearing, Gearbox, Engine

Product name:Piston Filling Machine

Material:Stainless Steel 304/316

Keywords:Fillng Machine

Usage:Filling Capping Labeling Packaging

Feature:High Precision Filling Level

Advantage:15 Years Experiences

Local Service Location:None

After Warranty Service:Video technical support Online support

After-sales Service Provided:Video technical support Online support

Certification:CE

MTW full automatic salad dressings mayonnaise nut butters jam can Garlic Sauce juice filling capping and labeling machine line

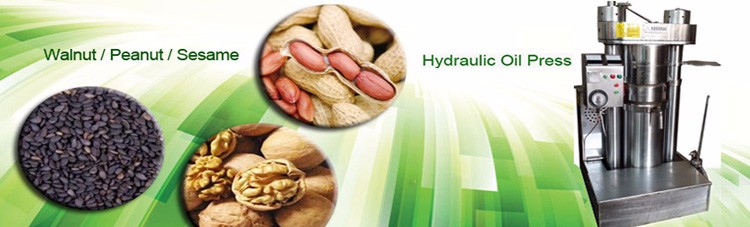

Plant raw materials: Rice bran, soybean, peanut, rapeseed, cottonseed, sunflower, palm, teaseed, flaxseed, corn germ, sesame, flaxseed, walnut, peony seed, castor bean, safflower seed, wheat germ…

Raw material

The oil production line is widely used in the production for various vegetable oils from the raw material to the final oil in the market. It is very popular for the production for edible oil and vegetable oils, such as sunflower oil, peanut oil, soybean oil,sesame oil, corn oil, palm oil, olive oil, castor oil, cottonseed oil, etc.

Working priciple

Working priciple

1.Advantage: nice shape, highly structured, easy installation, , fast warn-up and high oil output rate 2.New type:this kind of machine is our latest environment protection oil press.3.Main feature:this kind of combined oil press machine mainly has 3 parts: electric control box to control the machine working, oil pressing part, and vacuum filtering part for clearing oil.4.Function: hot press and cold press are available.5.Structure:6YL-B series integrated oil press machines are designed on the basis of the advantage of 6YL-series oil press6.Suitable place:this kind of machine is situable for small-medium factory and supermarket.

Advantage

Below features are based on oil plants above the average quality smoothly and continuously squeezed after such treatments as screening, husking, flaking and cooking, etc.Screw Soybean Seeds Oil Press / Groundnut Oil Mill Machine.Our machine adopt sea worthy wooden case packaging, safe and reliable.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are a reputed manufacturer and joint-stock enterprise with import & export rights andmainlyproduces oil press machinery and othersl equipment.Moreover, superior after-sales services guarantee highqualitycontinuously. In addition, we have a group of experienced and excellent after-sales service members who provide following up services for worldwide customers.Customers’ need is what we are trying to create. Customer satisfaction is what we are seeking. Over the last couple of decades, Benteng people have created continuously, transcending ourselves and insisting on the conceptof”Development is of overriding importance”. Develop the brand with quality. Promote the brand with service. We, Benteng people,areforging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Service

Pre-sale service1. Offer the professional solution and design drawing.2. Accept the customized model machine3. Accpect to visit factory4. Ffree testing5. Offer professional quotation6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service.

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.5.what kind of payment does your company support? T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.