Usage:Rapeseed Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:20-40 kg / hour

Place of Origin:Shandong, China

Brand Name:shishang

Model Number:DH-50

Voltage:220V/380V

Power:3200 w

Dimension(L*W*H):800 * 800 * 900mm

Weight:rapeseed oil machine, 100 kg

After-sales Service Provided:Overseas service center available

Certification:CE ISO

Product name:rapeseed oil machine

machine Size:800 * 800 * 900mm

Machine power:3200w

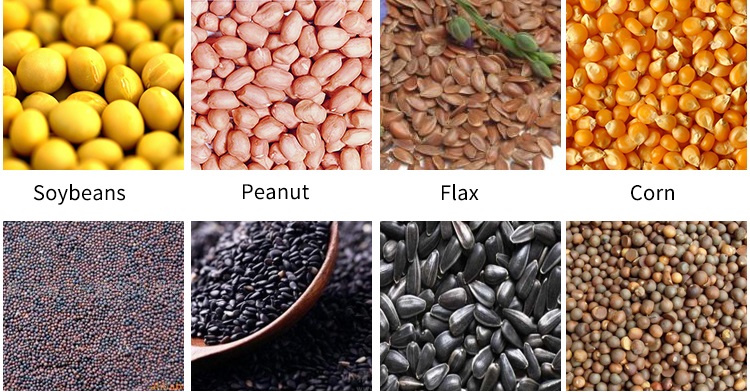

Ingredients:sesame seeds, peanuts, sunflower seeds, flaxseed, soybeans

Material:Stainless Steel 304

Application:Oil Production Line

Function:Making Edible Oil

Advantage:High Oilput

Warranty:One Year

Multifunctional rapeseed oil machine oil press machine seed oil making machine

Our Integrated oil press is used widely for processing rapeseeds, cottons, soybeans, peanuts, sesames, sunflowers, tung seeds, olive coconut meat,palm and other granulated oil materials, as well as using for rice bran, corn embryo and powered oil materials and safflower and other wild plant oil materials. It’s regeneration products for medium-small scale plant oil mill in country and private factory,and ideal choice for users to realize well-off life.

Raw material

Oil refining workshop application :Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil all refined oil.

Working priciple

Working priciple

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Advantage

Centrifugalization is a kind of method using centrifugal force to separate suspended impurities. Through the drum high-speed rotation of the centrifugal force separate the impurities form oil to reach solid and liquid separation. When the drum stops rotating, and net oil flow from the drum to achieve the purpose of filtering . The filtered oil can do edible test , no foam, no overflowed.

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

We are a professional oil and grain processing and refining equipment manufacturer in China, which is specialized in the research, design and manufacture of high quality equipment for making edible oils and other auxiliary products.Our company has engineer with more than 30 years of experience in the oil and grain industry and refining and fractionation industry. They are in charge of designing the machines, arranging the product line layouts, installing and adjusting equipment, training staff and working out the best formula for each client.

Service

1. We can manufacture according to your sample, design and technical indexes;2. We’ll provide you the whole program solution according to ur local customs, oil crops, local market demand;3. After sale, we’ll send our professionals to install and debug the machinery till you have learned all by yourself.

FAQ

1.Q :Are you the factory? A:Yes, We are a professional manufacturer for more than 10 years.2.Q: Where is your factory located? A:Our factory is located in Zhengzhou, Henan Province.3.Q:How about the INSTALLATION? A:Engineers are available to service machinery overseas,including installation,commission and training,etc. 4.Q:Can your company accept the customized product? A:Yes,OEM &ODM service is available.We can make the products according to your size,design,color, It will be better if you can send us the product pictures for our reference.5.Q: How does your factory do regarding quality control? A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.Any questions, please don’t hesitate to contact us!