Showroom Location:None

Condition:New

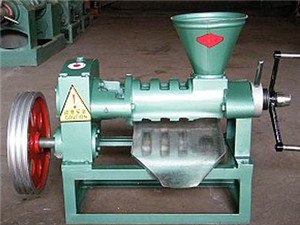

Usage:Oil Press

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Production Capacity:10t-30t/D for Cold Oil Press Machine

Place of Origin:China

Brand Name:Holyphant

Voltage:380V

Dimension(L*W*H):4365*700*2300mm

Weight:9000kg, 9000kg

Warranty:1 Year

Key Selling Points:High Productivity

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Video technical support, Online support, Engineers available to service machinery overseas

Certification:CE, ISO9001

New Big Oil Press:10t-30t/D for Cold Oil Press Machine

Cold Pressing:Suit for Walnut, Grape Seed, Almond Seed, Perilla

oil residue:6-7%

Size:4365*700*2300mm

hot pressing:suitable for soybean, palm kernel, cotton seeds, rapeseeds, etc

Application:Beans, Camellia Seeds, Flaxseed, Hemp Seeds, Perilla Seed

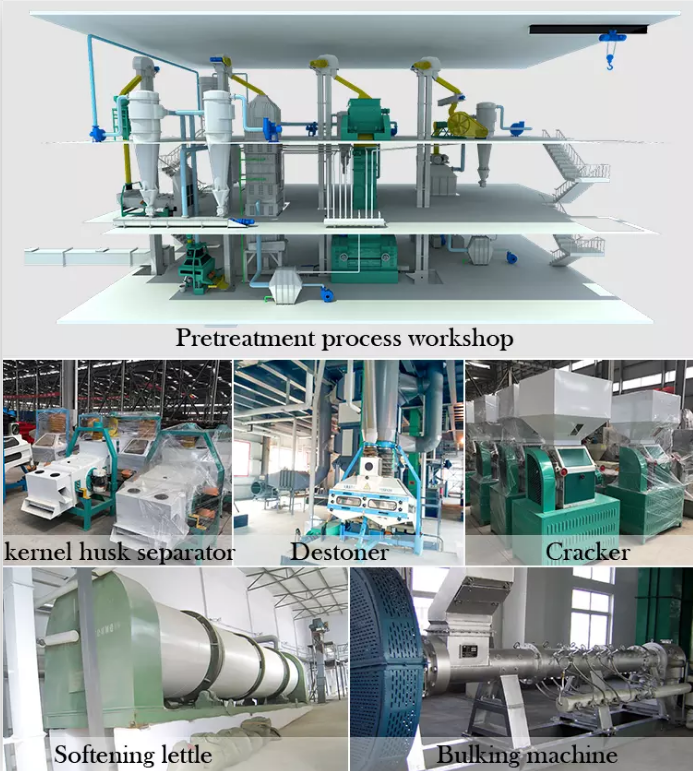

Machine Mainly:Matched with The Whole Oil Press Line

Oil Press Advantage:Low Temperature Pressing Under 60 Degree

oil machines cold press hemp seed oil press machine cold press oil extractor

This machine for coconut oil ,are also be fit for Almost all of the grain seeds can be pressed to make edible oil, such as corn, soybean, peanut, sunflower seed, flax seed ,coconut ,palm , rape seed.sesame, Olive, walnut,cocoa bean.,rice brain ,cotton seed ,castor seed.

Raw material

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Working priciple

Working priciple

1. Oil pressing linePeanut shell removing– peanut kernel cleaning-crushing–cooking–oil pressing–crude filter2.Oil refining lineDegumming–Deacidification–Decoloration–Deodorization–Oil Filter-Final edible peanut oil3.Oil Filling line

Advantage

1)Occupied workshop area is small.2)Special gear box structure make the rotating speed averagely.

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

1.we can free offer complete set 3-500 tons/24 hour cooking oil plant project offer . 2.we can do turn-key project, including design,installation, test and training 3.One-year free spare parts. 4.One-year quality gurantee. 5.Lifetime service.

FAQ

Usually the delivery time is 3-15 working days after prepayment received.Q7: What is the minimum quantity I must order?We don’t technically have minimums, but if you order more than 3 sets once,we can give you