Showroom Location:None

Condition:New

Usage:Palm Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Place of Origin:Henan, China

Brand Name:YINGDA

Voltage:220V

Dimension(L*W*H):700*700*900mm

Weight:156 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Marketing Type:Other

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Other, Gear, Gearbox

Oil type:Tea Seed Oil, SESAME OIL, sunflower seed oil, Almond Oil, Coconut Oil, OLIVE OIL

Max Capacity:30 kg/h

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Video technical support, Online support,attrValueId:190000884

Olive oil press / Screw oil press / Walnut oil press

soybeans, perilla seed, shelled hemp, flax seed, flax seed,camellia seed, walnut, black sesame, rapeseed, sesame, sunflower seed.Sunflower seeds, almonds, red / white pepper seeds, peanut, pumpkin seeds, pine nut, coconut meat.

Raw material

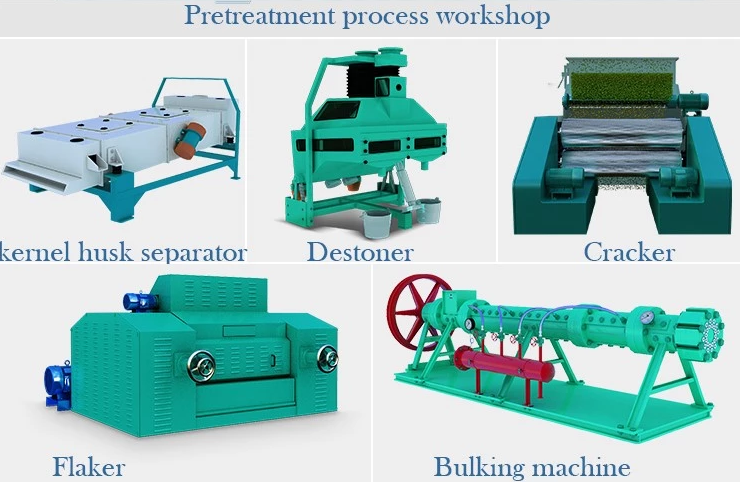

The oil production line is widely used in the production for various vegetable oils from the raw material to the final oil in the market. It is very popular for the production for edible oil and vegetable oils, such as sunflower oil, peanut oil, soybean oil,sesame oil, corn oil, palm oil, olive oil, castor oil, cottonseed oil, etc.

Working priciple

Working priciple

For the whole process of crude oil extraction machine, Please see below.The meal is fed through the inlet opening (1) into every stage of the steaming kettle (2), (3), (4) and is then gradually heatedup and stirred by the stirrer. Blades from one stage to another. After being pushed out from the outlet (5) of the bottom stage,it drops into the feed head (6) and is delivered to the pressing cage (7) to be compressed by various sections of the pressingworms therein. The extracted oil flows through gaps between cage bars into the oil screw conveyor (8) and thence to an oilreservoir, whereas the cake is discharged at the rear of the machine. All this shows that the whole process of oil extraction,beginning from feeding, steaming, heating up to oil and cake discharging, is fully automatic and continuous. Therefore, when oncethe amount, the temperature and the moisture of seeds and the thickness of cake have been set, the operator needs only to observethe feed indicating pointer, steam pressure gauges and ammeter and make adjustment when necessary, thus minimizing the requirementof supervision and greatly saving labor.

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a professional manufacturer of oil covering an area of more than 20,000 square meters, with a standardized heavy industrial plant, is a collection of r & d production, sales as one of the powerful enterprises.

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

1.Q: Which kind of oil materials can be processed?A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc.2. Q: What’s the input capacity of your machinery?A: 5-2000 tons per day. the input capacity is according your plan or requirements to customized.3. Q: The materials of your machinery?A: The stainless steel and carbon steel.4.Q: How should I do if meet some trouble while using?A:we can supply English manual book and also take a video for showing how to resolve the problems or dispatch our worker to your factory.5. Q: Can you install the machine in local place?A: We will send our engineers to local place to help installing the machine and provide technical guidance.6.Q: The production method of your oil machinery?A:divided into cold press and hot press two kind according the temperature,have physical direct press and solvent extraction etc. our machine can be meet your oil production.if any quotation,contact me free.7.Q: How long can we receive the goods?A:delivery about 45 working day after your order,have different shipping time of different machinery,and we will inform you shipping time based on your seaport.