Showroom Location:None

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

Warranty of core components:1 Year

Core Components:Motor

Brand Name:HDC

Place of Origin:China

Voltage:220v/380v

Power:3.6kw

Dimension(L*W*H):96*47*90cm

Weight:65 KG, 65kg

Warranty:1 Year

Application fields:Vegetable processing plant, Snack food factory, Beverage Factory, Fruit processing plant, Cooking oil factory

Machinery Function:seed roasting machine

Raw material:Corn, Nuts, Soybean, Pumpkin Seeds,peanut

Output product name:Peanut Roaster

Type:Grain Processing Equipment

Name:Peanut Roaster Machine

size:96*47*90cm

Heating method:Gas Electric

Product name:seed beans roasting machine

Application:Food Industry

Function:Roasting

Material:304 Stainless Steel

Peanut Baking Oven/Roast Nuts Machine with Non-stick material high quality

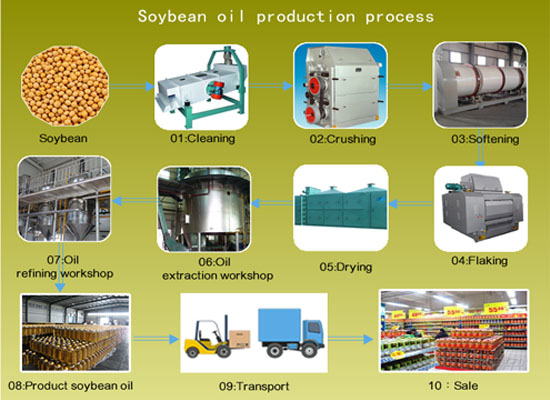

The Oil press is used to get the edible oil from vegetable oil seed and plant. Suitable for extracting different vegetable oil-materials, such as rapeseed, peanut, soybean, sesame seed, cottonseed, coconut, etc. This presser can press up to 5 ton raw material per day.

Raw material

Although 6YL-68 Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Working priciple

Working priciple

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantage

1,Innovative designs to meet various pretreatment and pressing of multiple oil seeds. Oil seed pretreatment and pressing equipments adopt advanced process design, being equipped with different process on basis of oil seed property. 2,Affordable oil processing solution with low cost. Gashili Food & Oil Machinery provides reasonable designed oil pretreatment and pressing machines with durable structure, low production cost and affordable invest on major oil equipment.3,Environmental protection and energy saving oil plant. Combing the consideration of local climate and water quality with oil pretreatment and pressing process, Gashili assures the most reliable and lowest cost oil machine designs for users worldwide. 4,Full set of production line and services. Gashili promises complete set of oil seed pretreatment & pressing machine production line including design, manufacturing and installation as well as on time after sale service.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

Since 1982, our company was found officially registered under Henan Companies Registry. Who is the leader in the oil press equipment field of China. The main products are hydraulic oil press machine, screw oil press machine, the accessory equipment for the oil press machine and other equipments.Our company has a professional design R&D team and sales team, backed by the university and guided by the market to update the products, The products have covered the reigion of China with nearly a million users. Our products had exported to many countries such as United States, India, South Korea, Russia, Somalia, Ethiopia, Sudan, Algeria, Bulgaria and so on, have received very good reputation.

Service

1.12 months warranty ,including core parts;2.Video support and online technical guidancem forever;3.Offer video support and online technical guidence at any time;4.Supply spare parts all the world;5.The worldwide agents have good policies and greatest support.

FAQ

Q1: What is the Warranty for the machines?A1: 1 year for free.Q2: What is the Material?A2: Stainless steel and carbon steel. Q3: When can I get the price?A3: Within 24 hours, if urgent, please directly call us.Q4: Whether the machine price can be more discount?A4: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our Manager to appropriately give you a little discount.Q5: How to ask quotation?A5: Please note us what tpye of raw seeds , and how many tons of raw seeds you want to treat per day, then we will send you quotation as soon as we can.Q6: Can we ask the oil plant for different types of oil?A6: Yes, but we recommend no more than 3 different types.Q7: Why need extraction ?A7: If only pressed, oil residue inside cake is very high at lease 6%. But after extraction, the oil residue will be less than 1%, which greatly increases the oil yield.Q8: Vegetable oil plants require how large of a workspace? A8: The land area typically depends on the capacity of the plant. We can suggest an appropriate space to prepare after given specifications, or, can design the oil plant in-house specifically to the amount of workspace available.Q9: How long will it take to receive my products?A9: As a general rule, it will take one Month for us to produce.