Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:80kg/batch

Place of Origin:Henan, China

Brand Name:SHUOMAN

Voltage:220V/110V/380V

Dimension(L*W*H):1500*580*1350mm

Weight:140KG

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

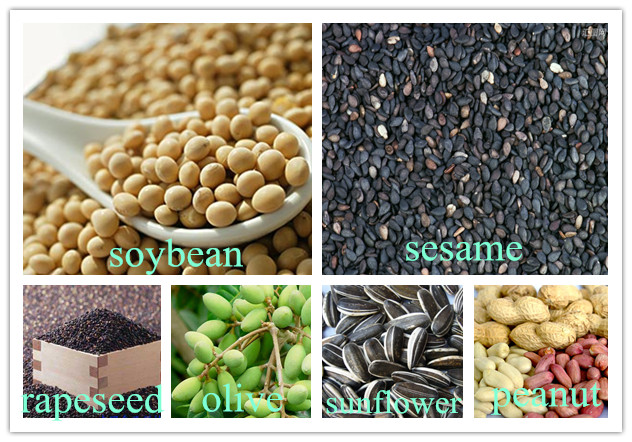

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil

Max Capacity:200 kg/h

Product name:mini crude oil refinery

Capacity:80-200kg/batch

Raw material:Stainless Steel

Tank diameter:50*60cm

Air pump Power:1.1Kw

Self-priming pump:1*0.37Kw

Application:sesame oil, peanut oil, sunflower seed oil, walnut oil, rapeseed oil

Keywords:mobile crude oil refinery

Working life:20 years

Package:Export wooden case

After Warranty Service:Video technical support, Online support, Spare parts

Local Service Location:None

After-sales Service Provided:Free spare parts, Video technical support, Online support

Certification:CE

Professional Automatic Modern And Advanced Mini Mobile Small Scale Crude Oil Refinery

various raw materials, as ground nuts, bean, rape and cotton seeds, sesame, olive, sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

Raw material

It can be used for various materials such as Peanuts, Rapeseeds, Sesame seeds, Soybeans, Cottonseeds, Tea seeds, Sunflower seeds, Palm kernel etc.

Working priciple

Working priciple

Magnitic seperating:In order to remove the metal impurities, so that can prevent damaging the equipment and occuring safety accidents.Cleaning: To remove the imourities in the raw matrial such as soil, stem and leaf, hull and moldy seeds.Husking: In order to improve the oil yielding rate and the quality of crude oil and meal, reduce the wear to the equipment, the hull must be removed.Cooking: This processing can improve prepressing oil yielding rate and the quality of the cake, adjust the moisture, temperature and plasticity of the flake.Prepressing:To squeeze out part of the oil in the raw material, and improve extracting effect.

Advantage

When the oil press is running, the processed material embryo enters the squeezing chamber from the hopper. The helix of the squeezed screw is pushed in and squeezed. The material embryo is carried out in the pressing chamber of the oil press. Under the condition of high pressure, there is a great friction resistance between the material embryo and the squeezing and squeezing chamber. The heat caused by the heat caused the thermal denaturation of the protein in the embryo, destroyed the colloid, increased the plasticity, and also reduced the viscosity of the oil and thus precipitated oil easily. The oil production rate of the oil press is improved.

Product Specification

Product Specification

| Type | 6YL-95DY | |||

| Capacity(t/24 h) | rapeseed | cottonseed | soybean | peanut kernels |

| 3.5-5 | 3.5-5 | 3.3-3.8 | 3.5-5 | |

| Oil Effiencicy(100%) | ≥95 | ≥95 | ≥95 | ≥95 |

| Equipped with power(kw) | Voltage:380V Power:11kw | |||

| Electric hearting part | Voltage:220V Power:2.8kw |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

1.12 months warranty ,including core parts;2.Video support and online technical guidancem forever;3.Offer video support and online technical guidence at any time;4.Supply spare parts all the world;5.The worldwide agents have good policies and greatest support.

FAQ

Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.