Applicable Industries:Food & Beverage Factory

Showroom Location:Turkey, Germany, Saudi Arabia, Russia, Argentina, Algeria, Kazakhstan, Tajikistan

Condition:New

Application:Beverage, Beverage

Packaging Type:Bottles

Packaging Material:Plastic, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:by other

Place of Origin:Jiangsu, China

Brand Name:BEYOND

Dimension(L*W*H):2100x1400x2300

Weight: KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

Filling Material:Oil

Filling Accuracy:accuracy

Marketing Type:Hot Product 2019

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, Other, PLC, Gear, Bearing, Gearbox, Engine

After-sales Service Provided:Engineers available to service machinery overseas

Control:PLC

Material:SUS304

Operation status:Stable

Quality:Hight

Processing:Oil

Rotary type oil Filling Machine for Edible oil

Automatic Cold Pressed Oil Extraction Castor Walnut Press Palm Refining Groundnut Peanut Oil Making Oil Expeller Machine is Suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame, sesame seed, tea seed, walnut, olive, corn germ, rice bran, tea seed, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

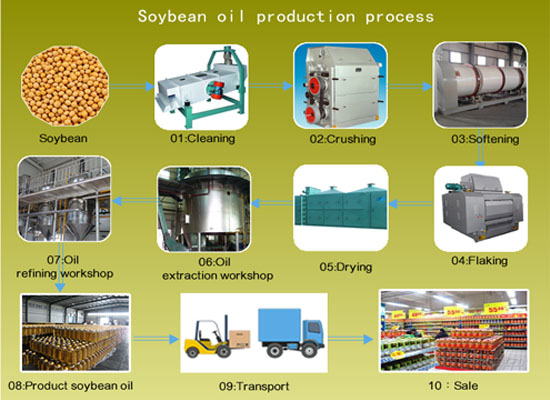

Oil refining workshop application :Soybean oil, sunflower seed oil, Rapeseed Oil, cottonseed oil, peanut oil, palm oil, copra oil, rice bran oil all refined oil.

Working priciple

Working priciple

(1)P-acid degumming operation:Drawing the filtered or settled crude oilinto the neutral pot, control oil temperature 40 ° C, liquidlevel cover theneutral pot volume about 80 %.Add into theneutral pot Pacid with 85% concentration, 0.1-0.2% oil weight.Start up neutral pot, make main shalf stirring at 60-70 r/min, finish de-gumming in 30 min.Adjust the neutral pot oil temp to about 85 °C, add into hot water whose temp higher oil temp 10-15° C, the water use amount each time is 10-15% oil weight.(2)alkali de-acid operationAfter finish degumming process, at once add into lye carrying alkali refining deacid, lye concentration 16 ° Be ′, super alkali is 0.1to0.3% oil weight, after finish adding, continuous stirring 30min, when soap particles accumulated condensing, should reduce stirring speed, 30r/min avoid emulsion. After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot drive part, theoil settled in the pot 6-8 hours, make oilseparate from soap.(3)de-coloring:Pump the oil netralized into decolorizer vessel , samely mixing to rise its temperature to 90 degrees,then mixing for 30 mins,to reduce water to 0.1% ,then put a little clay (decoloring media) 24 % of total oil ,mixing for 30 mins ,to reduce the temperature to 70 degrees, then filte the clay with oil filter,to get the oil decolorized .

Advantage

Materials are all sanitary stainless steel 304 or 316L .Humanized structure design and easy to operate .Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation .

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

We are a professional manufacturer of various machines. Our products has been exported to more than 55 countries in the world. We have good faith in working with you and we are sure our team is one of your best Choices in China.

Service

Before-sale services:(1)Guide customers to choose the best appliable machine type; provide the advanced, energy -saving and practical technological process.(2) We are responsible for the process chart and design.Sale services:(1)Products must be inspected strictly before selling;(2)In accordance with the agreements stipulated in the contract.(3)We will organize delivery.After-sale services:(1)Our company will send professional engineers to guide with device installation, debugging and training operators until customers are fully satisfied. Moreover, we will design and manufacture products, according to the special requirements of customers.(2)The quality guarantee period for machines is one year except the wearing parts.

FAQ

1. Q: How about the after service? A: We have a strong team, special for after service. We can arrange engineers to do service for you. And we insist ‘Quality is Life’. 2.Q: Are you factory or trading company? A: We are a factory in this field nearly 10 years; Welcome you come to China and have a visit.3. Q: Where is your factory located? How can I visit there? A: Our factory is located in Henan Province; Please contact us directly if you would like to come for a visit and we will pick you up . 4. Q: How does your factory do regarding quality control? A: Quality is priority. We always attach great importance to quality controlling from the beginning. We also promise 1 year guaranty, life-time technical support! 5. Q: why choose Our Machinery? A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.