Driven Type:Pneumatic

Voltage:220V

Place of Origin:China

Brand Name:Xinjiwang

Dimension(L*W*H):1040x360x360mm

Warranty:2 years

Key Selling Points:Easy to Operate

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:5 years

Core Components:Motor, PLC, Engine

Applicable Industries:Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, filling machine

Showroom Location:None

product name:Fully pneumatic horizontal filling machine

Keywords:cream filling machine

MOQ:1PCS

Usage:cosmetic cream, lotion, shampoo, etc

Control:Pneumatic Control System

filling volume:5-100ml

Material:SUS 304 316

Capacity:5-50bottle/per minuter

Advantage:Simple Structure

filling accuracy:±1

Type:Filling Machine

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

Application:Food, Beverage, Commodity, Medical, Chemical, Pharmaceutical

Packaging Type:Cartons, case

Packaging Material:Wood

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Machinery Capacity:4000BPH, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

Weight:30

Certification:ce

Filling Material:Oil, cosmetic cream liquid and paste filling machine

Filling Accuracy:99%

Semi-automatic engine oil lubricant oil filling machine car oil filling machine

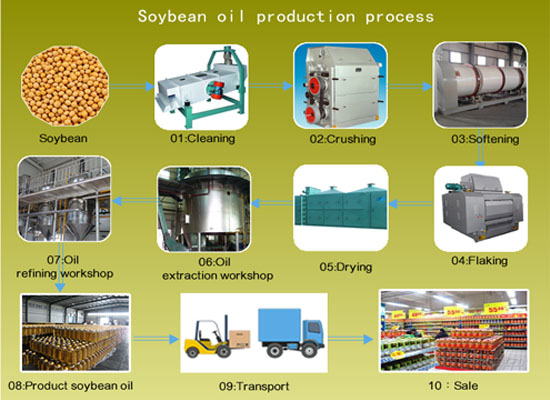

This screw cold&hot press series can process sesame seed, rapeseed, peanut, soybean, cottonseed, almond, Tung-oil seed, sunflower seed, tea seed, walnut, caster seed, Perillaseed , Hazelnut,oil palm, oil olive, avocado, pomegranate seed , pistachio nut, neem seed, coconut, totally about 150 types of seeds , nuts,beans , fruits and oil crops;

Raw material

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Working priciple

Working priciple

The flow chart process of palm oil processing machinePalm fruit bunches–Sterilizing–Threshing–Digesting–Pressing–Clarifying–Filtering–Drying–Crude palm oil.

Advantage

Product Features1. The pressure value is greater, the oil output rate is higher, and more safety.2. Hard chrome electricity instead of decorative chrome.3. The load-bearing panel and load-bearing column are made of special steel instead of ordinary steel to ensure durability and safety.4. Each key parts have professionally inspection. No defective plate is allowed for equipment manufacturing.5. Use high-quality motor to ensure strong heart power. Low failure rate.6. Patent barrel, increase the oil output on the premise of ensuring strength.7. Reduce the height of the bottom plate of the main engine, and improve the dust-proof effect of the fuel tank.

Product Specification

Product Specification

| Sunflower Oil Quality Index (The index of soybean oil, rapeseeds oil, oiltea seed oil are similarly) |

|||

| Item | Quality index | ||

| Crude oil | 1st grade | 2nd grade | |

| Colour and lustre(25.4mm) | _ | Y15 R1.5 | Y25 R4.0 |

| Flavor and taste | Crude sunflower oil smell, no peculiar flavour | The original sunflower flavor, no peculiar flavour | The original sunflower flavor, no peculiar flavour |

| Transparency | _ | Clear and transparent | Clear and transparent |

|

Moisture & Volatile matter / % ≤ |

0.2 | 0.1 | 0.15 |

|

Impurities/% ≤ |

0.2 | 0.05 | 0.05 |

|

Acid value (KOH)/(mg/g)≤ |

4 | 1 | 2.5 |

|

Peroxide value/ (mmol/kg) ≤ |

7.5 | 6 | 7.5 |

|

Solvent residue /(mg/kg) ≤ |

100 | Not be detected | Not be detected |

| Test tempeature (280 °C) | _ | No educt, Lovibond Tintometer:Yellow value not changed,red value increasing<0.4 | Trace of educt, Lovibond Tintometer: Yellow value not changed,red value increasing<0.4 blue value<0.5 |

Company Profile

We are a reputed manufacturer and joint-stock enterprise with import & export rights andmainlyproduces oil press machinery and othersl equipment.Moreover, superior after-sales services guarantee highqualitycontinuously. In addition, we have a group of experienced and excellent after-sales service members who provide following up services for worldwide customers.Customers’ need is what we are trying to create. Customer satisfaction is what we are seeking. Over the last couple of decades, Benteng people have created continuously, transcending ourselves and insisting on the conceptof”Development is of overriding importance”. Develop the brand with quality. Promote the brand with service. We, Benteng people,areforging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Service

We always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.We are willing to supply good service on your business development.

FAQ

a discount.Q8: Do you have machines in stock?Yes, we have some models oil press in stock.Q9: How will my order be packed, can you provide the installation service?Packed in plywood case. We will send English manual. If the customer need, we will send one engineer for assembling and training for workers.