Applicable Industries:Hotels, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Construction works , Energy & Mining, Food & Beverage Shops, juice factory, semi automatic filling machine

Showroom Location:None

Condition:New

Application:Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware

Packaging Type:CANS, Bottles, Barrel, Stand-up Pouch, Bags, Pouch, case, container

Packaging Material:Wood

Automatic Grade:Semi-automatic

Driven Type:Pneumatic

Voltage:220V

Place of Origin:Hunan, China

Brand Name:Rulang

Dimension(L*W*H):820*670*1450mm

Weight:90kg

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:400BPH, 500BPH, 100BPH, 200BPH, semi automatic filling machine

Filling Material:Beer, Milk, Water, Oil, Juice

Filling Accuracy:+/-1%

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pump, Engine

Product name:Semi automatic filling machine

Air pressure:0.5-0.7MPa

Filling range:10-5000ml

size:820*670*1450mm

weight:90Kg

Other name:semi auto filling machine

Power:300W

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE

Semi automatic filling machine 2 nozzles semi automatic filling machine 5 liter oil semi automatic filling machine

It can be used for oil extraction from peanut kernel, sunflower seed kernel,cotton seed, soybeans, rapeseed,safflower seed,castor seed and other oil crops.

Raw material

Screw press is suitable for pressing rapeseed, peanut kernel, soybean, olive, walnut kernel, corn germ, rice bran, tea seed, safflower seed, sea buckthorn seed, neem seed, rubber seed, pepper seed, tomato seed, watermelon Vegetable oils such as seeds, grape seeds, flaxseed, evening primrose, pepper seeds, castor beans, citrus seeds, cocoa beans, coffee beans, perilla, almonds, peach kernels, and rose hips.

Working priciple

Working priciple

Main Equipments of edible oil extraction machine:1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.2. Roary extractor: spray and soak the cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).3. DTDC: used to separate the solvent from the wet meal.4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.5. Miscella tank 2nd: the purified miscella will be pumped into it.6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantage

1) Simple structure ,easy in installation and maintation. 2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 3) Running in a high automatization and intellectualization,no pollution 4) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine . 5) Suitable to losts raw materials such as peanut, sunflower seeds, black seeds, olive, coconut, flax seeds, etc.

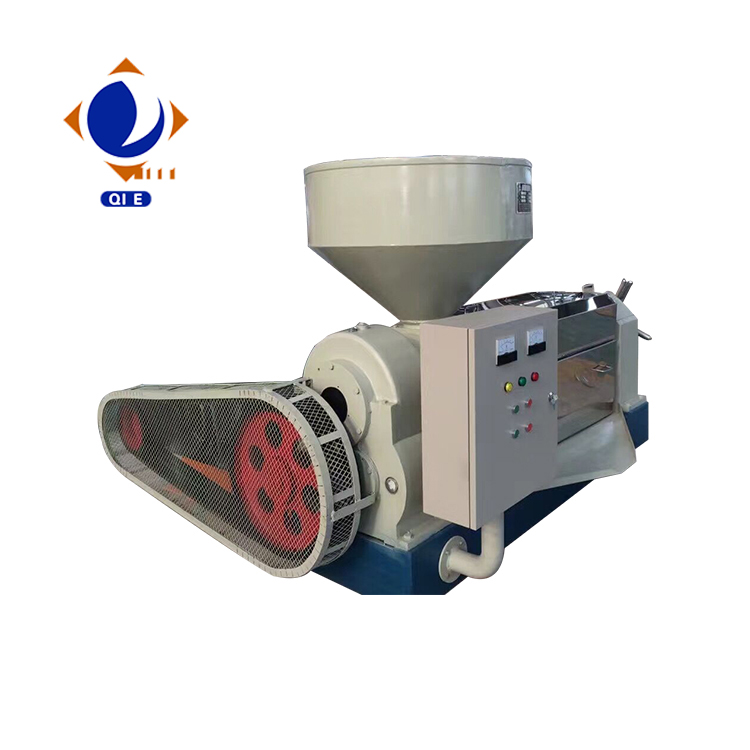

Product Specification

Product Specification

| Oilseeds | Processing Capacity (kg/h) | |

| 95DFY | 110JDFY | |

| rapeseed | 150-220 | 250-300 |

| cottonseed | 150-220 | 250-300 |

| soybean | 140-340 | 230-270 |

| peanut | 150-220 | 250-300 |

| Oil efficiencies(%) | ≥95% | ≥94% |

| Motor for pressing(kw) | 11(380V) | |

| Motor for oil filtering(kw) | 3(380V) |

Company Profile

We are a China manufacturing and project engineering company with a global outlook, specializing in the design, production and supply of quality machines and integrated systems for the Edible Oil Production.

Service

Pre-sale services:Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investment(1) Select equipment model;(2) Design and manufacture products according to clients’ special requirement;(3) Train technical personnel for clients.After-sale services:(1) Assist clients to prepare for first construction scheme;(2) Install and debug the equipment;(3) Examine the equipment regularly;(4)Take initiative to eliminate the troubles rapidly at site;(5)Provide technical exchanging;(6)Provide maintenance for big items

FAQ

Q1: What is the Material?A1: Stainless steel or carbon steel.Q2: When can I get the price?A2: Within 24 hours, if urgent, please directly call us.Q3: Whether the machine price can be more discount?A3: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our Manager to appropriatelygive you a little discount.Q4: How to ask quotation?A4: Please note us what tpye of raw seeds , and how many tons of raw seeds you want to treat per day, then we will send youquotation as soon as we can.Q5:Does the screw oil press need to be heated?A5:Yes, it does. Preheat with dry oil cake for 30 minutes before feeding seeds normally.Q6: How many people are required to operate this screw oil press?A6: 1-2 people can operate.