Showroom Location:None

Condition:New

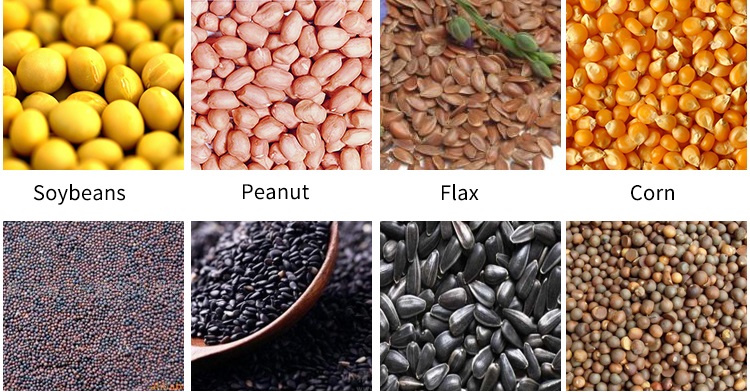

Usage:soybean,corn,peanut,sesame,rapeseed,rice bran,cottonseed,tea seed, rice bran,soybean oil edible oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:9-11 Tons per day

Place of Origin:Henan, China

Brand Name:Kinetic

Voltage:220V/380V/440V

Dimension(L*W*H):2850*1850*3270mm(depend on capacity)

Weight:5000 kg(depend on capacity)

Warranty:1 Year

Key Selling Points:Automatic

Marketing Type:OTHER

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

After-sales Service Provided:Engineers available to service machinery overseas, Video technical support, Online support

Item:rice bran oil making machinery

Capacity:10t/d, 20t/d, 30t/d, 40t/d, 50t/d, 60t/d, 70t/d, 80t/d,100t/d, 150t/d

residual oil rate:≥ 97%, meal residual: ≤ 1%, press cpress cake residual: ≤ 6%

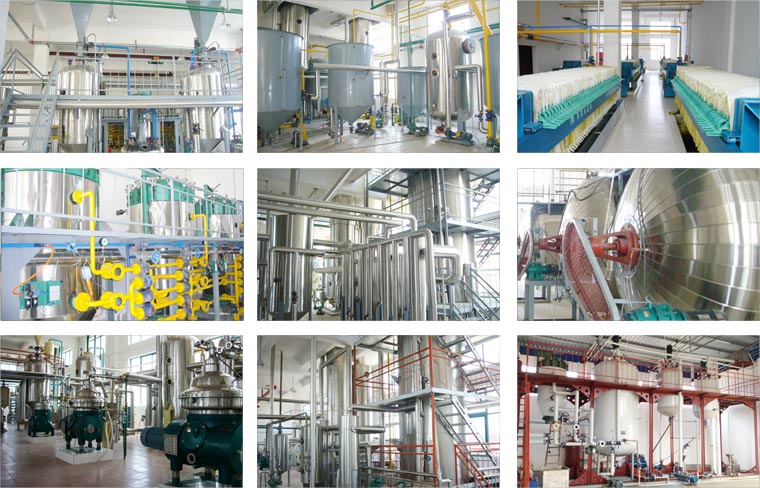

processing steps:pretreatement, extracting, cleaning

Raw material:carbon steel & stainless steel

Color:Clients’ Requirements

Advantage:full automatic, high efficiency, energy saving

Function:oil press

After Warranty Service:Online support

Local Service Location:None

Certification:ISO CE

small cooking oil making machine/extraction sunflower oil solvent extraction plant for rice bran oil

This cooking oil extraction machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ, and so on.

Raw material

Automatic oil machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Working priciple

Working priciple

Palm oil is a tropical woody vegetable oil. It is the largest variety of vegetable oil in the world in terms of production, consumption and international trade. Because of the particularity of oil palm fruit structure, its oil-making technology and equipment are quite different from other oils. The oil-making process of palm oil mainly includes the following parts:sterilization and fermentation, threshing, mashing and cooking, pressing oil, crude oil purification, oil storage, separation of kernels and fibrous substances, separation of kernels and kernels, and storage of kernels.

Advantage

Advantages :1.Easy to operate2.It can effectively and quickly separate the phospholipid colloidal impurities from the crude oil.3.Equipped with damping device, no anchor bolts are needed, with lower noise.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-230 | Vertical | 35-55kg/h | 900×850×1550 |

| 6YY-260 | Vertical | 45-70kg/h | 1050*950*1650 |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We have abundant experience in product research, strong technical force, sophisticated production, and specializing in production of oil press machine, the main products are automatic Hydraulic oil press, and related products: wok, vibrating screen, peanut sheller, sesame feeding machine, oil filter machine, spiral hoist, automatic seed feeding machine. Our hydraulic oil press is suitable for a variety of oil crops(sesame, peanut, walnut, mustard, olive, sunflower and more), all parts of the machine are made up of premium alloy steel and excellent craftsmanship, won an excellent reputation and satisfaction among customers.Welcome customers from worldwide come for a visit to our factory!

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.