Applicable Industries:Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Beverage, Chemical, Commodity, Food, Medical, Beer, Milk, Water, Oil, Juice, cream

Packaging Type:Cartons, CANS, Bottles, Barrel

Packaging Material:Plastic, Paper, Metal

Automatic Grade:Semi-automatic, Semi-Automatic

Driven Type:Pneumatic

Voltage:220V/50HZ 110V/6OHZ, 220v/110v

Place of Origin:Guangdong, China

Brand Name:Chiyuanxin

Dimension(L*W*H):1200*300*300mm

Weight:30kg

Warranty:1 Year

Key Selling Points:High-accuracy, Easy to Operate

Machinery Capacity:8000BPH

Filling Material:Milk, Water, Oil, Juice, liquid

Filling Accuracy:±1%

Marketing Type:Hot Product 2019

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Gearbox, Engine, Air Cylinder

Product name:Automatic one head bottle filling machine for liquid

Filling accuracy:≤±0.5%

Air pressure:0.4-0.6Mpa

Filling speed:15-30 Bottles/min

Material:Stainless steel

Control:Button

After Warranty Service:Video technical support, Online support, Spare parts

Local Service Location:None

After-sales Service Provided:Online support, Video technical support

Certification:CE Certificate

Small manual semi automatic 10 ml -5 litter juce carbonated drink lubricant oil edible oil eliquid filling machine for wine

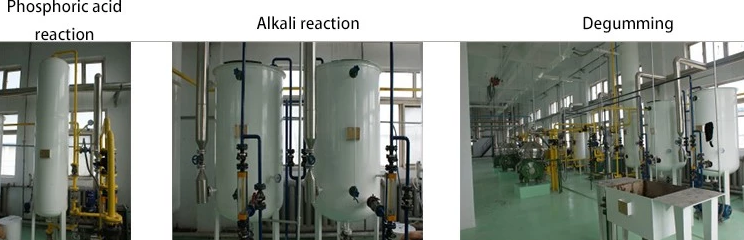

This Screw oil extraction machine for peanut soybean cottonseed making cooking oil processing machine is suitable for rapeseed,mustard, peanut, soybean, sunflower, coconut, flaxseed, sesame seed, cotton seed, tea seed, walnut, corn germ, rice bran and soon.

Raw material

suitable to all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Working priciple

Working priciple

1.Material enters the extruding chamber from the hopper.2.There is quite strong friction among press screw, chamber and the oil materials.3.Root diameter of the pressing screw carries larger from one end to the other.4.Last,helping protein change property, damage colloid, increase plasticity, decrease oil’s elasticity, resulting in high oil.

Advantage

Advantages of cooking oil making machineThe whole extraction workshop is selected on the base of safety,reliable,energy-saving, less fault,easy maintenace,and long using life,adopting world advanced technology and equipment to achieve the beat process effects.Features of cooking oil processing machine:Applicable for various kinds of low oil content raw material,like rice bran, rapeseed, cotton, corn germ etc cakes for max oil yield. After extracting ,the resid oil is lower than 1%.

Product Specification

Product Specification

| Model | Capacity | Power | Electric machinery | Packing size(mm) | Gross andnetweight(kg) |

| 6YL-80oil press machine | 80-150Kg/h | 5.5KW | 380V/50HZ/Triple phase | 1510*440*700 | 350/330 |

| 6YL-95/100oil press machine | 150-200Kg/h | 7.5KW | 380V/50HZ/Triple phase | 1910*550*765 | 450/420 |

| 6YL-120oil press machine | 200-300Kg/h | 11KW | 380V/50HZ/Triple phase | 2100*630*770 | 530/500 |

| 6YL-130oil press machine | 300-400Kg/h | 15KW | 380V/50HZ/Triple phase | 2280*700*780 | 780/750 |

| 6YL-160oil press machine | 400-600Kg/h | 18.5KW | 380V/50HZ/Triple phase | 2050*600*850 | 950/900 |

Company Profile

We have abundant experience in product research, strong technical force, sophisticated production, and specializing in production of oil press machine, the main products are automatic Hydraulic oil press, and related products: wok, vibrating screen, peanut sheller, sesame feeding machine, oil filter machine, spiral hoist, automatic seed feeding machine. Our hydraulic oil press is suitable for a variety of oil crops(sesame, peanut, walnut, mustard, olive, sunflower and more), all parts of the machine are made up of premium alloy steel and excellent craftsmanship, won an excellent reputation and satisfaction among customers.Welcome customers from worldwide come for a visit to our factory!

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

Chrome steel or Stainless steelQ6: How long does it take to produce the machine once I place my order ?