Showroom Location:None

Condition:New

Usage:SESAME OIL

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:30-60kg/hour

Place of Origin:China

Brand Name:HENGYI

Voltage:Local Voltage

Dimension(L*W*H):800x650x1100mm

Weight:750KG

Warranty:1 Year, 12 Months

Key Selling Points:Sustainable

Marketing Type:Hot Product 2019

Machinery Test Report:Not Available

Video outgoing-inspection:Not Available

Warranty of core components:1 Year

Core Components:Motor, Pump

Oil type:SESAME OIL

Max Capacity:50kg/h

extraction of oil from groundnut:extraction of oil from groundnut

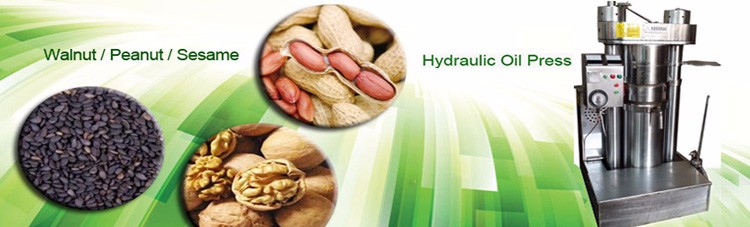

Function:sesame, walnut, lavender…oil press

Pump:hydraulic pump

Advantage:high oil yield

Multi-purpose:Yes

Production capacity:100%

oil standard:pure

color:silvoil press home machineer

delivery:on time

After Warranty Service:Video technical support, Online support

Local Service Location:None

After-sales Service Provided:Online support

Certification:CE ISO CCC

sunflower seed oil press vegetable oil production extraction of oil from groundnut

The machine Could press rapeseed, cottonseed, soybean, peanut, flaxseed, palm, coconut shell, olive fruit, castor bean, sesame, sunflower, rice bran, corn germ, walnut, almond, evening primrose, Pine seeds, animal skin, clay and all oil crops.

Raw material

Screw press is suitable for pressing rapeseed, peanut kernel, soybean, olive, walnut kernel, corn germ, rice bran, tea seed, safflower seed, sea buckthorn seed, neem seed, rubber seed, pepper seed, tomato seed, watermelon Vegetable oils such as seeds, grape seeds, flaxseed, evening primrose, pepper seeds, castor beans, citrus seeds, cocoa beans, coffee beans, perilla, almonds, peach kernels, and rose hips.

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

small business flaxseed sesame oil press groundnut processing oil machine adopt newest technology. Its advantage:1. Easy to operate.2. High oil yield.3. Extensive use.

Product Specification

Product Specification

| Processing capacity | 3.5T–11T Per day. |

| Residue oil of the cake | ≤7.8% |

| Temperature control power | 3.0kw |

| Main electromotor power | 11kw |

| Spiral axes rotate speed | 32-40 |

| Weight | 1000kg-1400kg |

Company Profile

We are a professional manufacturer of oil covering an area of more than 20,000 square meters, with a standardized heavy industrial plant, is a collection of r & d production, sales as one of the powerful enterprises.

Service

Pre-sales Service1.Offering comprehensive technical and business consultation services;2.Proposing th e most suitable scheme and equipment for our clients;3.Designing and fabricating targeted products according to the special requirements of clients;4.Training periodically high qualified service technician.After-sales Service1.Highly inspecting equipment in every working procedure, quality comes first;2.Fast & Safe Delivery;3.Assisting our clients for foundation construction of equipment;4.Dispatching engineers to install and debug equipment;5.Training the first-line operators on site;6.Regularly visit clients to solve production problems;7.Providing life-long maintenance service;8.Providing technical exchanging;

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.