Showroom Location:Viet Nam

Condition:New

Usage:Solid Liquid Separation

Type:Pressing Machine

Automatic Grade:Automatic

Production Capacity:High Efficiency

Place of Origin:Henan, China

Brand Name:Dazhang

Voltage:Customized

Dimension(L*W*H):5690*1840*1630(mm)

Weight:11750 KG

Warranty:1 Year

Key Selling Points:High Productivity

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Bearing

Oil type:Coconut Oil, Palm Oil

Max Capacity:1000 kg/h

Material:Carbon steel

Filter plate material:PP

Plate Shifter:Automatic

After Warranty Service:Field maintenance and repair service

Textile Dyeing Industry Mud Automatic PLC Frame Press Filter Machinery

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Raw material

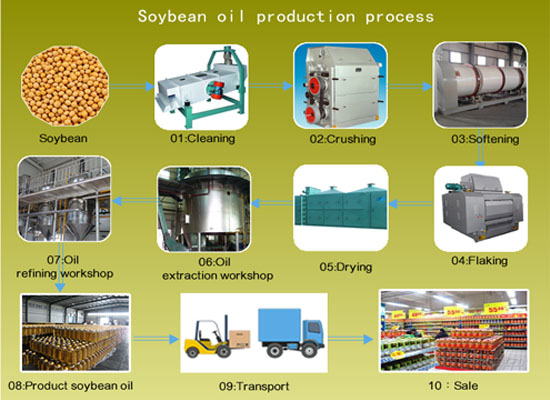

Our oil refining line Application:Our refining machine is suitable for refining various of crude oil, vegetable oil, such as palm kernel oil, sunflower seed oil, tea seed oil, peanut oil, soybean oil, corn oil, groundnut oil, rapeseed oil and so on.

Working priciple

Working priciple

Screw expeller pressing is to separate the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of screw oil expeller, they have similar theories in screw expeller pressing.Because the screw type seed oil expeller is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process.

Advantage

(1)The lubrication should be checked after every 50 hours of operation. The oil cup on the gearbox should not be short of oil. The screw shaft should be adjusted from the adjustment screw hole to the oil in the screw hole. Dry grinding is strictly prohibited.(2)The parts of the oil should be protected from dust and other impurities. The quality of the oil in the gearbox should be checked once a year. If it is found to be deteriorated, all oil should be replaced.(3) When the crushing amount is reduced and the cake or oil is not normal, the screw shaft should be taken out to check the wear of the screw, the strip and the cake ring, and the worn parts should be replaced in time.

Product Specification

Product Specification

| Made in china seeds oil press machines/cottonseed oil expellerSpecification : | ||||

| Model | Capacity (ton/day) | Power (KW) | Packing size( mm) | Gross Weight (KG) |

| AST-80 | 2~3 | 5.5 | 1510x440x695 | 370 |

| AST-95-1 | 3~5 | 7.5 | 1920x620x770 | 700 |

| AST-100 | 3~5 | 7.5 | 1920x650x770 | 710 |

| AST-120 | 4~6 | 11 | 2060x630x790 | 720 |

| AST-120C | 6~8 | 15 | 2100x700x800 | 750 |

| AST-130 | 9~12 | 18.5 | 2300x700x770 | 850 |

| AST-160 | 15~20 | 22 | 2500x700x850 | 980 |

Company Profile

We are a group joint-equity enterprise, specializing in producing edible oil equipment for various kinds of grain, including corn, soybean, sunflower, palm, flaxseed, peanut/groundnut, and etc. Qi’E integrates scientific research, manufacturing, sales as one. So far, Qi’E equipment and service have been exported to more than 30 countries, countries such as Russia, India, Sounth Africa, Indonesia, Nepal, Canada, Argentina, and etc.

Service

Our company always put the interests and quality of its clients first, insists the principle that there is no best but only better service. We will commit to provide quality products and improve on-site service and service after selling. Specific commitments are now as follows:We will organize an experienced engineering team, managed by the Project Manager.Ensure high-quality materials, excellent service provided to the user;During the installation process, we will appoint a technical and installation supervision services at the scene.We do debugging of stand-alone equipment and on-line debugging and commissioning test run to ensure normal operation of the project at full load conditions.Supply the technical of your staff to ensure training of personnel to operate independently for free.To ensure that once installation acceptance; Within one month, to provide customers with qualified acceptance after completion of archive.To ensure timely provision of equipment and accessories;We have developed new products, new technology, will give priority to customers;In the equipment’s warranty period (within 12 months of the date of commissioning qualified):Due to the quality of the equipment itself damage, we will repair or replace parts.Damage due to customer reasons, only charge the material cost for repair or replacement by the buyer. After the customer informed our company, we will put forward a propose within 24 hours, using the fastest way to resolve the issue the required components.

FAQ

A : Manufactured strictly based on national and international standard, and we take a test on every equipment before delivery.5.Q:Can you install the machine in local place?A: Yes, engineers can be dispatched to your local place for installation and commissioning, also provide operation training.6.Q: What’s the payment terms?A:T/T,Trade Assurance,Western Union, MoneyGram,L/C, Cash etc.