Applicable Industries:manicure

Showroom Location:Russia, Spain

Condition:New

Application:Chemical, gel polish,nail polish,oil,water

Packaging Type:Bottles

Packaging Material:Paper

Automatic Grade:Semi-automatic

Driven Type:Electric

Voltage:110v-220v

Place of Origin:China

Dimension(L*W*H):670*430*560mm

Weight:37 KG

Warranty:2 years

Key Selling Points:High-accuracy

Machinery Capacity:1000BPH

Filling Material:Water, Oil, gel polish, nail polish

Marketing Type:New Product 2020

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, PLC, Engine

Product name:Liquid Pouch Filling Packing Machine

Function:Automatic Filler

Bottle type:PET Plastic Bottle

Filling range:2-50ml 10-150ml 30-300ml 50-500ml 100-1000ml

Material:Stainless Steel

Filling speed:3s/pcs

Suitable for:Water Filling Line

Advantage:time-saving,money-saving

Operation:Semi-automaticn

Packing type:Cartons

After Warranty Service:Video technical support, Spare parts

Local Service Location:Russia, None

After-sales Service Provided:Video technical support, Free spare parts

Certification:CE

The most convenient digital control high precision table top semi automatic liquid nail uv gel nail polish filling machine

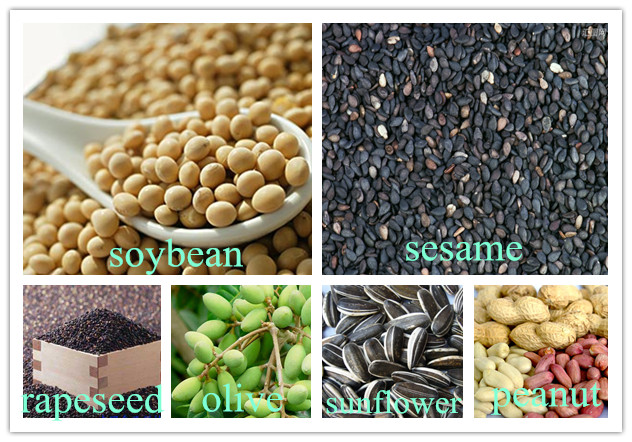

Although 6YL-68 Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Raw material

Pretreatment Applicable oil: soybean, rice bran, sunflower, rapeseed, cottonseed, walnuts, corn germ, peanuts, copra, castor bean, palm kernel, palm nuts, sesame, olive and the like.

Working priciple

Working priciple

Structure of oil refining machine:1.small edible oil refinery machine structure:The machine is consist of hydration deguming&deacidification system, filter de-coloring, transmission system, oil liquid conveyingsystem, transmission and lubrication system, electrical control system and machine frame. 2.hydration deguming&deacidification system of our small edible oil refinery machine:This part is consist of mixer, deguming tank, gum outlet and transfer pipe3.filter de-coloring system of our small edible oil refinery machine:This part is consist of oil inlet, a sealing cover, cover handle, fine filter bucket, oil collecting tank, filter cloth, and oil outlet.4.transmission system of our small edible oil refinery machine:This part is consist of speed control motor, motor controller, governor and power module5.electrical control system of our small edible oil refinery machine:This part is consist of miniature circuit breaker, motor controller, power supply module, contactor, relay, potentiometer and knob.

Advantage

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Product Specification

Product Specification

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a reputed manufacturer and joint-stock enterprise with import & export rights andmainlyproduces oil press machinery and othersl equipment.Moreover, superior after-sales services guarantee highqualitycontinuously. In addition, we have a group of experienced and excellent after-sales service members who provide following up services for worldwide customers.Customers’ need is what we are trying to create. Customer satisfaction is what we are seeking. Over the last couple of decades, Benteng people have created continuously, transcending ourselves and insisting on the conceptof”Development is of overriding importance”. Develop the brand with quality. Promote the brand with service. We, Benteng people,areforging ahead for first-class brand with innovative spirit and do our best to contribute to the national industry.

Service

Before-sale services:(1)Guide customers to choose the best appliable machine type; provide the advanced, energy -saving and practical technological process.(2) We are responsible for the process chart and design.Sale services:(1)Products must be inspected strictly before selling;(2)In accordance with the agreements stipulated in the contract.(3)We will organize delivery.After-sale services:(1)Our company will send professional engineers to guide with device installation, debugging and training operators until customers are fully satisfied. Moreover, we will design and manufacture products, according to the special requirements of customers.(2)The quality guarantee period for machines is one year except the wearing parts.

FAQ

1.Are you a trading company or a manufacturer?We are a manufacturer.2.How to study to operate this machine?You may View the operation video to study how to operate it.3. If the machine is damaged during use, how to maintain it?Please contact us to obtain the spare parts support.4. What is the price?We offer a price range on the website, If you want to know the exact price, please inform us of the port of destination.5. I’m a stranger to large machines, what should I do?we provide paid services such as the installation, debugging and technical training to customers who buy large machines. Of course, You can also come to our factory for free training.6.How to become a local agent?If you want to be an agent to develop the local market, please contact us.