Applicable Industries:Food & Beverage Factory, Farms, Home Use, Retail, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Food, Beverage, Chemical

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Metal

Automatic Grade:Semi-automatic

Driven Type:Electric

Voltage:220V

Place of Origin:Henan

Dimension(L*W*H):220*150*220cm

Weight:460KG

Warranty:1 Year

Key Selling Points:High-accuracy

Machinery Capacity:2000BPH

Filling Material:Liquid

Filling Accuracy:≤0.5

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

Product name:Automatic Weighing Filling Machine

Filling Error:≤0.2%

Material:Stainless Steel

Filling volume:1-20KG

Filling material:liquid,or less paste

Packing speed:100-130 barrels/head/hour

Bottle diameter:No limited

Numbers of nozzle:6 heads( can customized)

Control mode:PLC

Advantage:Factory price

After Warranty Service:Video technical support

Local Service Location:None

After-sales Service Provided:Online support, Video technical support

Certification:CE

YZH Automatic Six Heads Bucket Drums Blue Iron Barrel Packing Chemicals Solvents Water Weighing Filling Machine

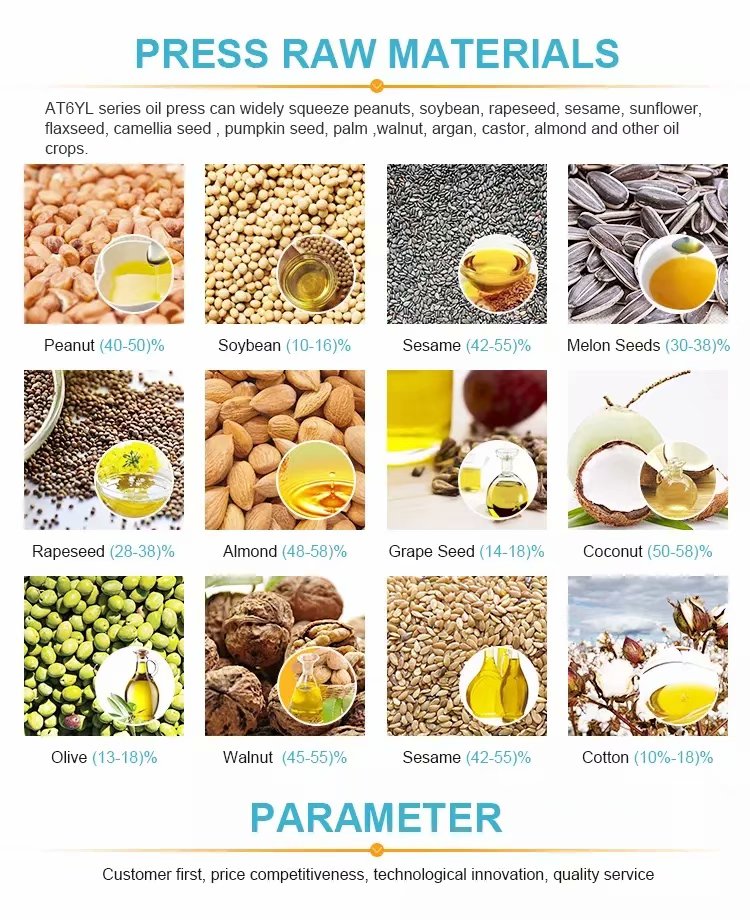

It can be used for various materials such as Peanuts, Rapeseeds, Sesame seeds, Soybeans, Cottonseeds, Tea seeds, Sunflower seeds, Palm kernel etc.

Raw material

1.Hot oil material classes: sesame seeds, flax, peanut, wheat germ, corn germ, etc;2.Cold oil material classes: pine seeds, almonds, olive, walnuts, camellia seed, macadamia nuts, etc3.Spices and traditional Chinese medicine,pepper, mustard seed, purple perilla, etc;4.Good quality oil,pure physical squeeze, high oil, does not destroy the organic components of oil.

Working priciple

Working priciple

Automatic Cold Pressed Oil Extraction Castor Walnut Press Palm Refining Groundnut Peanut Oil Making Oil Expeller Machine is to separate the oil from oil bearing materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil materials. Under the big pressure created in press chamber, the oil can be discharged from gap of press bars and oil trough of press rings. Either big scale and small scale of oil press machine, they have similar theories in screw expeller pressing. Because the screw type oil press machine is mainly used by extrusion theory, so it is also called as oil extruder or oil extrusion process.

Advantage

(1) High oil yield , obvious economic benefit.(2)Residual oil rate in the dry meal is low.(3)Improving the quality of the meal and oil.(4)Low processing cost , high labor productivity.(5)High automatic and labor saving.And more other advantages please contact me now,we will provide profession program for you,and we accept custom according your requirements.

Product Specification

Product Specification

| Raw Material | Capacity(kg/hr) | Output Rate(%) | Cake Residual | |

| Rape seeds | Hot pressing | 150-170 | 30-38 | 7.5-8 |

| Cold pressing | 75-95 | 28-35 | ||

| Peanut | Hot pressing | 150-185 | 35-45 | 7 |

| Cold pressing | 65-95 | 32-40 | ||

| Soybean | Hot pressing | 135-160 | 10-16 | 6.5-7 |

| Cold pressing | 70-105 | 8-14 | ||

| Sesame | Hot pressing | 150-185 | 44-47 | 6.5-7.5 |

| Cotton seeds | Cold pressing | 95-105 | 10-14 | 5.5-8.5 |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

1. One year quality warranty for the machine and spare parts2. Overseas engineers service for installation3. Whole-life after-sales service and free consultation4. Customized requirements available5. Technician guide at the site.6. 24Hr online service

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.