Condition:New

Usage:To make peanut sunflower oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Automatic

Production Capacity:98%-100%

Place of Origin:Henan, China

Brand Name:Doing

Voltage:380V

Dimension(L*W*H):900*850*1550

Weight:780kg

Warranty:1 Year

After-sales Service Provided:Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support, 1-5tpd small scale cooking oil production line

Certification:CE ISO

Capacity:1-5tpd

Raw material:Soybean, sunflower seeds, sesame

Keyword:scale cooking oil production line

Oil content in oil seeds:about 18-50%

Function:getting cooking oil

Manufacturing experience:40 years experience in cold press oil expeller machine

Material of equipment:stainless steel and carbon steel

Advantage:Easy Operation

Press type:Single Screw Shaft

1-5tpd small scale cooking oil production line with filling machine to make peanut sunflower oil

This oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ,etc.

Raw material

Pretreatment Applicable oil: soybean, rice bran, sunflower, rapeseed, cottonseed, walnuts, corn germ, peanuts, copra, castor bean, palm kernel, palm nuts, sesame, olive and the like.

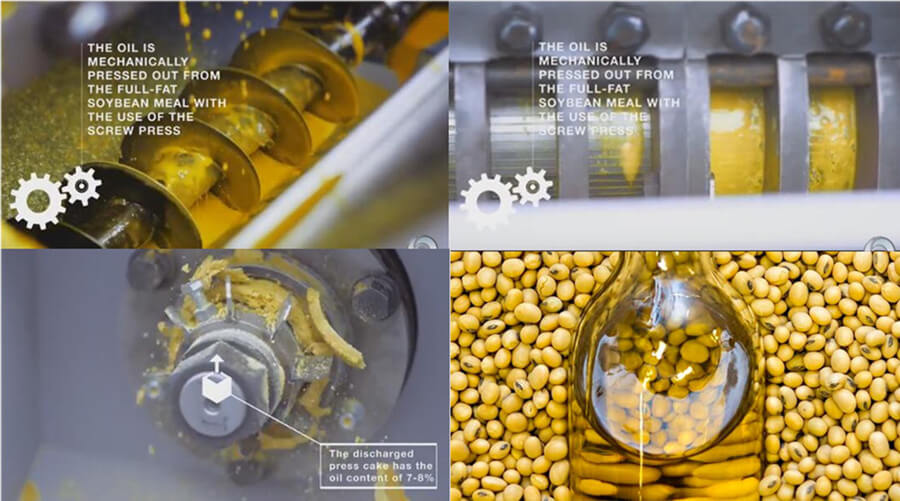

Working priciple

Working priciple

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.Cleaning the SeedsThe harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.Grinding the SeedsThe de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.PressingThe heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.Refining of the OilOil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Advantage

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Product Specification

Product Specification

| Model | 6JY-60 | 6JY-70 | 6JY-80 | 6JY-100 | 6JY-125 | 6JY-150 |

| Squeeze spiral Diameter | 55mm | 63mm | 80mm | 100mm | 125mm | 150mm |

| Squeeze screw speed | 64r/min | 63r/min | 63r/min | 43rmin | 36rmin | 36r/min |

| Power | 2.2kw | 3kw | 5.5kw | 7.5kw | 11kw | 15kw |

| Heating power | 0.9kw | 1.5kw | 3kw | 3.5kw | 4kw | 4kw |

| Capacity | 30-60kg/h | 60-90kg/h | 80-130kg/h | 200-260kg/h | 300-350kg/h | 450-500kg/h |

| weight | 230kg | 280kg | 565kg | 760kg | 920kg | 1200kg |

| size(LWH) | 1200*800*1160 | 1400*950*1250 | 1650*1500*1600 | 2000*1500*1720 | 2100*1500*1750 | 1600*2100*1720 |

| Voltage | 220v | 220v | 380v | 380v | 380v | 380v |

| Model | Capacity(t)/Day | Power(KW) | Material | Loading size(container) | Process range |

| YHJ-03 | 1.8T | 30.95KW | SUS304/316 | 20GP | 1-4 Grade |

| YHJ-05 | 3T | 37.45KW | SUS304/316 | 20GP | 1-4 Grade |

| YHJ-10 | 6T | 46KW | SUS304/316 | 40HQ | 1-4 Grade |

| Oil Seeds | Oil Extraction Rate(%) | Dry Cake Residual Oil Rate(%) |

| Sesame | 42-55 | ≤7 |

| Rape Seed | 28-38 | ≤8 |

| Sunflower | 30-38 | ≤8 |

| Peanut | 40-50 | ≤8 |

| Soybean | 10-16 | ≤7 |

Company Profile

We are a group joint-equity enterprise, specializing in producing edible oil equipment for various kinds of grain, including corn, soybean, sunflower, palm, flaxseed, peanut/groundnut, and etc. Qi’E integrates scientific research, manufacturing, sales as one. So far, Qi’E equipment and service have been exported to more than 30 countries, countries such as Russia, India, Sounth Africa, Indonesia, Nepal, Canada, Argentina, and etc.

Service

Q1.What’s your advantage? Why we choose you?A:More 30 Years experience of design and manufacture grain and oil machinery.We have the most professional techniques and team. More advantage in price.Q2.What’s the Payment?A:T/T would be better with quick transfer and few bank fees. L/C could also be accept, but the procedure is complex and the fee is high. You can also use Western Union and Paypal.Q3.Are you a factory or trading company?A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.Q4: Can you show how the machine works?A: Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better. Q5: How can I know your machine works well?A: Before delivery, we will test and adjust the machine working condition for you, then you can use directly when you get it. Q6: Do you have ISO certificate?A: For every model of machine, it has a ISO certificate.

FAQ

1. Q: How about the after service? A: We have a strong team, special for after service. We can arrange engineers to do service for you. And we insist ‘Quality is Life’. 2.Q: Are you factory or trading company? A: We are a factory in this field nearly 10 years; Welcome you come to China and have a visit.3. Q: Where is your factory located? How can I visit there? A: Our factory is located in Henan Province; Please contact us directly if you would like to come for a visit and we will pick you up . 4. Q: How does your factory do regarding quality control? A: Quality is priority. We always attach great importance to quality controlling from the beginning. We also promise 1 year guaranty, life-time technical support! 5. Q: why choose Our Machinery? A: We are one of leader in this field(in China). Our quality products and service have enabled us to expand our market from china to more than 60 countries.