Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location:Egypt, Canada, Turkey, United States, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Russia, Spain, Thailand, Morocco, Kenya, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia

Condition:New

Application:Beverage

Packaging Type:CANS, Bottles, Barrel

Packaging Material:Plastic, Metal, Glass

Automatic Grade:Automatic

Driven Type:Electric

Voltage:According to customer requirements

Place of Origin:Jiangsu, China

Brand Name:King Machine

Dimension(L*W*H):According to customer requirements

Weight:5000 KG

Warranty:2 years

Key Selling Points:High-accuracy

Machinery Capacity:4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

Filling Material:Water, Oil, Juice

Filling Accuracy:±3mm

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

Keywords:soft drink filling machine

Function:Bottle Washing Filling Capping

Filling material:soft drink

Bottle type:PET Plastic Bottle

Material:Stainless Steel 304/316

Capacity:2000-30000bph

Filling volume:200ml-2000ml

Control:PLC+ Touch Screen

Processing Types:Normal Pressure Filling

Product name:Automatic Carbonated Soft Drink Filling Machine

1000-6000-32000bph High Speed Automatic 3 in 1 CSD Carbonated Beverage Soda Sparkling Water Soft Drinks Filling Machine

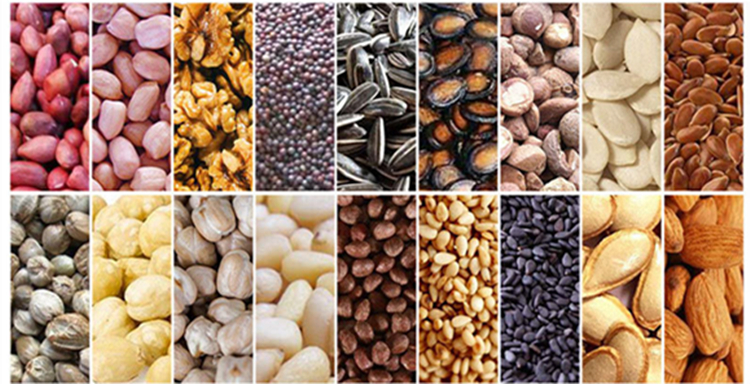

Our Integrated oil press is used widely for processing rapeseeds, cottons, soybeans, peanuts, sesames, sunflowers, tung seeds, olive coconut meat,palm and other granulated oil materials, as well as using for rice bran, corn embryo and powered oil materials and safflower and other wild plant oil materials. It’s regeneration products for medium-small scale plant oil mill in country and private factory,and ideal choice for users to realize well-off life.

Raw material

Processing materials: sunflower seed, peanut, mustard, almond, black sesame, tea seed, cottonseed, etc

Working priciple

Working priciple

depending on the oil, the production process different crude oil, customer demand for products of different, the size of the processing and refining method is different, our company’s refining equipment is divided into three types: batch refining equipment and semi continuous refining equipment and continuous refining equipment.

Advantage

3)High hardness and strength, good abrasion resistance and long using life.4)Vegetable oil seeds, corn ,sunflower ,soybeans, peanuts, cotton seeds, sesame seeds,palm kernel,coconut etc.5)Compact structure, stable function, simple maintenance.6)Efficient oil producing, easy operating, high automatic.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are a Professional and modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation. We have obtained rich experience and practice in palm fruit oil machine, vegetable oil pretreatment, prepress,extraction, sophisticated technology and equipment designs etc, owing wide international market in more than 130 countries and regions.With more than 30 years of experience on oil making machine, we provide a comprehensive range of products We are proud to guarantee that, with our strong technical background and communication capability, our sales/support engineers are able to answer your most complicated technical questions over the phone in English. That would save a lot of time for communication.The following pictures show our company and customers in our workshop.

Service

Pre-sale service1. Offer the professional solution and design drawing.2. Accept the customized model machine3. Accpect to visit factory4. Ffree testing5. Offer professional quotation6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service.

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.5.what kind of payment does your company support? T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.