Applicable Industries:Hotels, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

Showroom Location:Egypt

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Hot Product 2020

Warranty of core components:1 Year

Core Components:Bearing, Motor

Brand Name:Ultron

Place of Origin:Henan, China

Voltage:110v/220v/380v

Power:60kw

Dimension(L*W*H):10000*1100*2200mm

Weight:900 KG

Warranty:2 years

Application fields:Vegetable processing plant, Cannery, Commercial catering, Cooking oil factory, Meat processing plants, Seasoning plant, Snack food factory, Frozen food Factory

Machinery Function:making potatao chips, french fries

Raw material:Fruit, Wheat, Nuts, Vegetables, Water, Fruit, Vegetables, Potato

Output product name:potatao chips | french fries, potato chips | french fries

Key Selling Points:High Productivity

Name:frozen french fries production line price

Keywords:frozen french fries production line

Key words:small scale frozen french fries production line

Usage:making potatao chips, french fries

Machinery::pretreatment line for 50kg/hr french fries

Machine Material:Food grade 304 stianless steel

Heating source for Blanching and Frying:Gas,Electricity, Diesel

French fries size:Custom made

100kg/h Small Scale Semi-Automatic Frozen French Fries Production Line with Factory Price

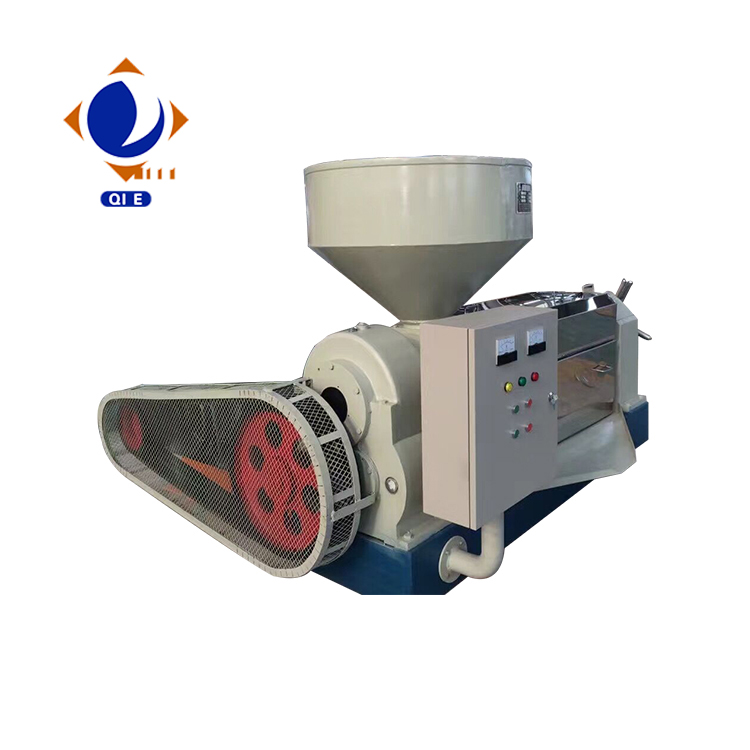

This oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ,etc.

Raw material

This oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, corn germ,etc.

Working priciple

Working priciple

Main Process of cooking oil refinery machine:1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.3. Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Advantage

(4)After the end of each shift, the residual cake in the machine should be removed and the dust and grease on the surface of the machine should be wiped clean.(5) When storing for a long time after the end of the production season, maintenance should be carried out once, and the snails, the squeezed strips, the cake strips should be removed and washed and re-applied, and placed in a dry place.

Product Specification

Product Specification

| Item | 5TPD Peanut oil production line |

| Capacity | 5TPD |

| Power | 44kw |

| Installation size | Oil pressing line+oil refining line+oil filling line15m*2.5m*4.5m(L*W*H) |

Company Profile

Our company is a professional manufacturer of food oil machines. On the basis of advanced equipment and workmanship, we have excellent production technicians and an efficient distribution team, as well as good service staff members, so that we can undertake your orders very efficiently and offer services very effectively. When we have the confidence on the high quality of our products, we offer very competitive prices at the same time. Our business depends on your business and our purpose is “supporting you”. We mainly provide popular products with high quality at home and abroad and create competitive advantages for our customers for their own competition. In addition, you can suggest any design or give any special requirement for our products and we will do our best to settle them for you. We believe our honesty and sincerity will make any cooperation agreeable. We look forward to long-term and prosperous cooperation with customers around the world. If you have any inquiry, please don’t hesitate to contact us and we are on duty during the whole 24 hours. Your satisfaction is exactly what we pursue. Best wishes for your business along with our sincere gratitude for your attention.

Service

Pre-Sales Service* professional sales team.* 24 hours online service.* visit our Factory.After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas.

FAQ

1.Q: How about the after service?A: We have a strong team, special for after service. We can arrange engineers to do service for you. And we insist “Quality is Life”.2.Q: Are you factory or trading company? Where is your factory located?A: We are a factory in machine development; Our factory is located in Zhengzhou Henan Province, welcome you come to China and have a visit.3.Q: Do you have English install step or vedio ?A: Sure, we have.Will send it to you when you need it.4.Q: How does your factory do regarding quality control?A: Quality is priority. We always attach great importance to quality controlling from the beginning.5.Q: why choose Our Machinery?A: We are one of leader in this field(in China). Our quality products and servicehave enabled us to expand our market from china to more than 60 countries.6. Q: How long will you send the machine after I pay?A: Normally, about 5-7 days. Also, if urgent, pls contact with us.7. Q: How can I pay?A: By T/T(wire transfer),Western Union, Money Gram, Alibaba Trade Assurance.Pls feel free to contact us if you want get more information or any question ! !