Applicable Industries:Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops, Other

Showroom Location:Canada, France

Condition:New

Application:Beverage, beer

Packaging Type:Barrel

Packaging Material:Metal

Automatic Grade:Semi-automatic

Driven Type:Electric

Voltage:AC110-380V, 220V

Place of Origin:Jiangsu, China

Brand Name:Maidinglong

Dimension(L*W*H):600mm*750mm*1650mm

Weight:120kg

Warranty:1 Year

Key Selling Points:Competitive Price

Machinery Capacity:40Barrel/H (20L), 90Barrel/H (20L)

Filling Material:Beer, Other, Milk, Water, Oil, Juice, Powder

Filling Accuracy:0.05%F.S.

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Pressure vessel, Other, PLC

Product name:filling machine

Capacity:40-90Barrel/hour

Function:Washing Filling Capping

Keywords:Beer Fillng Machine

Barrel volume:10L to 50L

Control:PLC+ Touch Screen

Filling material:Liquid cola /beer/ juice

Product:can of cola juice beer

Barrel type:Keg

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Viet Nam, Philippines, Indonesia, Thailand, Japan, None

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:ce,iso

10L 20L 30L 40L 50L Beverage Beer Barrel Washing Barrel Filling Machine Production Line

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Raw material

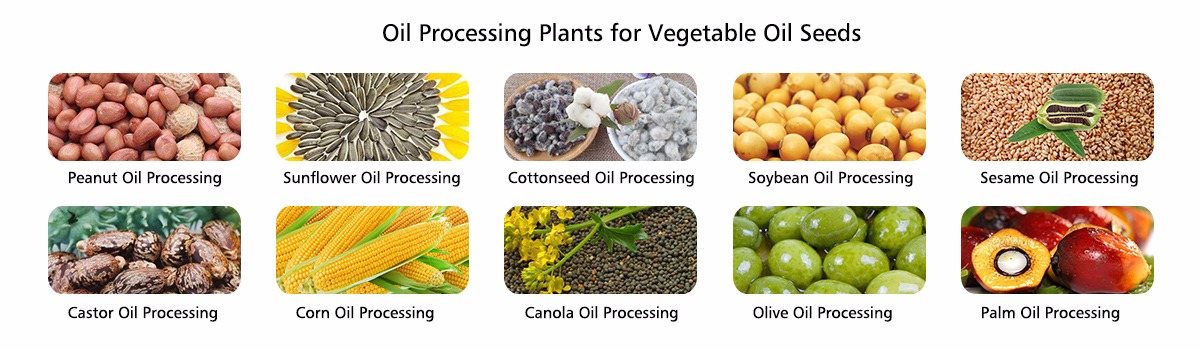

Our oil refining line Application:Our refining machine is suitable for refining various of crude oil, vegetable oil, such as palm kernel oil, sunflower seed oil, tea seed oil, peanut oil, soybean oil, corn oil, groundnut oil, rapeseed oil and so on.

Working priciple

Working priciple

The technology flow of cooking oil solvent extraction machine:The process is like oil extracted – wet meal desolvation – mixed oil vaporation – stripping by steam – solvent recoveryMaterial embryos→Extraction→Wet meal→Evaporation→Cooling→Product meal packing ↓Mixed oil→Filter→Negative pressure evaporation → Crude oil ↓Solvent recovery

Advantage

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Product Specification

Product Specification

| Model | Type | Processing Capacity | Dimensions (mm) |

| 6YY-230 | Vertical | 35-55kg/h | 900×850×1550 |

| 6YY-260 | Vertical | 45-70kg/h | 1050*950*1650 |

| 6YY-360 | Horizontal | 80-120kg/h | 2800×800×1500 |

| 6YY-460A | Vertical | 60-110kg/h | 1000×1300×1950 |

| 6YY-460B | Vertical | 50-100kg/h | 1100×800×2000 |

Company Profile

We are a professional oil and grain processing and refining equipment manufacturer in China, which is specialized in the research, design and manufacture of high quality equipment for making edible oils and other auxiliary products.Our company has engineer with more than 30 years of experience in the oil and grain industry and refining and fractionation industry. They are in charge of designing the machines, arranging the product line layouts, installing and adjusting equipment, training staff and working out the best formula for each client.

Service

1.Pre-sales Service-Professional and comprehensive pre-sales service guides and directs your investment.a>Introduce the situation and product categories of our company;b>According to the local market demands, guide the users to choose the right product category;c>According to the production demand and investment scale, guide the users to choose the right products;d>Accompany on-the-spot investigation on production, introduce the production processes and explain the difficult problems;e>According to the actual situation, work out a flexible investment solution for you;2. On-sale service-Meticulous and scientific on-sale service makes your choice more worry-saving and reliable.a>Review the contact, confirm or amend the uncertainties or the issues that have to be fixed through negotiations by both parties.b>Assign production orders and arrange production as per requirement.c>Provide the plant layout of workshop and foundation drawing of equipment in advance. We will arrange personnel to carry out on-site guidance if necessary.d>Provide technical consultation as well as the advices on the plan of factory establishment.e>Monitor the production schedule of equipment on a real-time basis to ensure punctual delivery.3.After-sales service-Thoughtful and prompt after-sales service provides support and guarantee for your benefits.a>Send the technicians to guide the installation and training workers and try running. (Countries or regions with unstable political situation or in the throes of wartime are not included in our plan).b>Train the users to command the equipment and guide them for safe production.c>Explain the routine maintenance of equipment carefully and remove common faults.d>We are responsible for all the repairs that caused by our quality problems within one year’s warranty. Foreign accessories are generally delivered by DHL in order to provide service for foreign customers promptly.e>The foreign customers who have any questions on after-sales service can directly send email to our designated mailbox. We will answer your questions within 12 hours and solve various problems for the customers in time.f>For some counties whose visas are difficult obtain, customers can also send their technicians to our company to receive free guidance and training.g>Accept the suggestions for improvement put forward by customers in an earnest way. In accordance with changes of the market, provide the products and services to meet the users’ needs and create values for them.h>The customers whose products have passed its warranty date are entitled to enjoy our after-sales service for life.

FAQ

Q1:What the terms of payment you accept?A1:T/T 50% deposit first, balanced 50% should be paid before delivery.Q2:Does you have stock now?A2:Yes we have enough stock to meet your larger orders.Q3:What materials your machine can press?A3: Our hydraulic oil press machine can press kinds of materials, such as soybean, sesame, cottonseed, walnut, camellia、peanut and so on.We can also test especial materials for you.Q4:Can your machine work at a low temperature?A4:Yes. Our machine has the heating system to fit for the low temperature, increase oil rate.Q5:How long is your guarantee?A5:One year guarantee, we supply free exchange for spare parts. After this period, we offer the spear parts with facotry price. You will be welcomed to contact us with any problem might occurred.