Applicable Industries:Hotels, Manufacturing Plant, Food & Beverage Factory, Food Shop, Food & Beverage Shops

Showroom Location:None

Condition:New

Application:Beverage, Chemical, Commodity, MEDICAL

Packaging Type:CANS, Bottles

Packaging Material:Glass, Metal, Plastic

Automatic Grade:Automatic

Driven Type:Electric

Voltage:220V/380V

Place of Origin:Shanghai, China

Brand Name:HIGEE

Dimension(L*W*H):1500mm X 900mm X 1500mm

Weight:500 KG

Warranty:1 Year

Key Selling Points:Easy to Operate

Machinery Capacity:2500-3000

Filling Material:nasal spray liquid, essential oil, i-drop liquid

Filling Accuracy:±1%

Marketing Type:New Product 2021

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

Name:Automatic Liquid Filling Machine

Function:pet bottle filling capping machine

Filling type:Peristaltic Pump Filling

Filling head:4

Capping head:1

Production capacity:60 bottles per minute for 10ml bottle

Bottle size:10-150ml

Liquid:nasal spray liquid

Product:eye drop liquid

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:None

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:CE

10ml 30ml nasal spray filling line electronic smoke filling capping machine eye drop liquid filling machine

Our Oil Extraction Machine are modern products developed and improved our company newly. Automatic oil press machine is suitable for rapeseed, peanut, soybean, sunflower, rapeseed, sesame seed, tea seed, walnut, olive, corn germ, rice bran, safflower seed, seeds of hippophae rhamnoides and so on.

Raw material

soybeans, perilla seed, shelled hemp, flax seed, flax seed,camellia seed, walnut, black sesame, rapeseed, sesame, sunflower seed.Sunflower seeds, almonds, red / white pepper seeds, peanut, pumpkin seeds, pine nut, coconut meat.

Working priciple

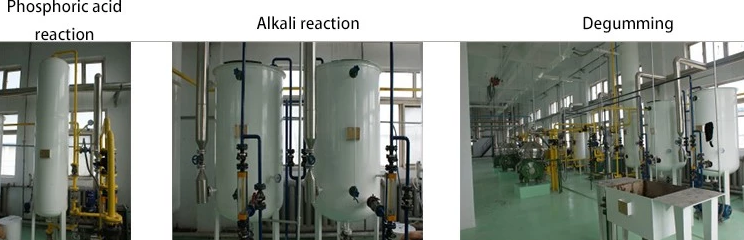

Working priciple

Flow Chart of Small scale edible oil refinery plant coconut oil processing machine production line:Crude Oil→ Filter→ Degumming→ Deacidification→ Decoloring→ Deodorizing→ Dewaxing→ Defeat→ First Grade Oil

Advantage

We meet the demands of virtually every application in the vegetable oil processing industries. With premium quality oil mill machinery, oil extraction machines and professional oil processing systems & oil refining technologies in the field of vegetable oil extraction and refineries, you can depend on our equipment and expertise to help you hulling, crushing, conditioning, flaking, cooking, extruding, expelling, extracting, degumming, neutralizing,dewaxing/fractionation.

Product Specification

Product Specification

| Processing capacity | 3.5T–11T Per day. |

| Residue oil of the cake | ≤7.8% |

| Temperature control power | 3.0kw |

| Main electromotor power | 11kw |

| Spiral axes rotate speed | 32-40 |

| Weight | 1000kg-1400kg |

Company Profile

We are engaged in food grain and oil engineering design, new technology development, machinery and equipment manufacturing, engineering, installation and commissioning of the entire training services in one of the professional engineering company.Company institutions are: engineering technology, marketing services, integrated management of the Ministry of Finance Management Department, machinery manufacturing center and research and development centers and other departments. Including engineering and technical design staff of nearly 20 people, designed to work in all computer operations, forming a set of scientific research, production and development as one of scientific research and development based engineering company.Our project covering more than 20 domestic provinces, municipalities and autonomous regions, and exports of South Africa, Ethiopia, South Asia, Pakistan, Russia and dozens of countries, the company manufacturing may bear 2000t / d pre-crushing and leaching, 600t / d refinery and other large equipment and engineering installation and commissioning.Companies adhere to the “credibility of the first, leading technology” business philosophy, and gradually formed a service-oriented corporate culture. Adhere to high standards, to provide customers with high quality personalized service.

Service

Pre-sale service1. Offer the professional solution and design drawing.2. Accept the customized model machine3. Accpect to visit factory4. Ffree testing5. Offer professional quotation6. Free consult and technical supportAfter-sale service1. Online technology support.2. Free video support.3. Free spare parts during the warranty period.4. Field maintenance and repair service.

FAQ

1. Can you teach me to operate the machine?A : Our machines are full assembled before shipping,and we also offer instructions.You just follow the steps.Besides,you can call me for any questions.2.Can you give warranty of your products?A: Yes, we extend a 100% satisfaction guarantee on all items. We also provide inspection video.Please feel free to feedback immediately if you are not pleased with our quality or service.3.Where are you? Can I visit you?A: Located in Zhengzhou, Henan,the company welcome to you visit our factory at any time.4.How about the delivery time?A: Within 25-45 days after we confirm you requirement.