Showroom Location:None

Condition:New

Usage:Peanut Oil

Type:Cold & Hot Pressing Machine

Automatic Grade:Semi-automatic

Production Capacity:20kg/h

Place of Origin:Zhejiang, China

Brand Name:Surri

Voltage:220V/single phase

Dimension(L*W*H):70x40x90cm

Weight:60 KG

Warranty:1 Year

Key Selling Points:Multifunctional

Marketing Type:New Product 2020

Machinery Test Report:Not Available

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor

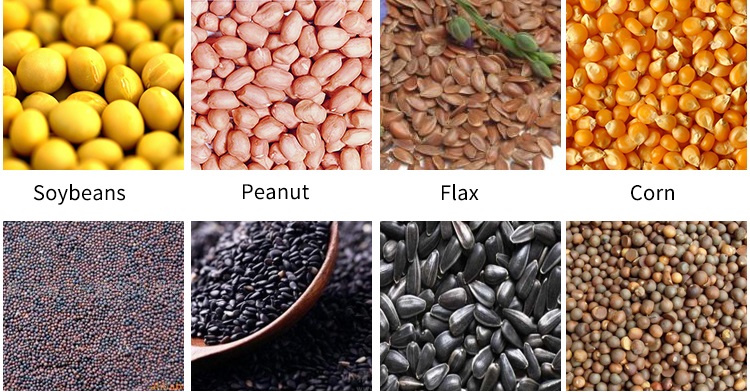

Oil type:Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

Max Capacity:4kg/h

After-sales Service Provided:Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Item:commercial sesame peanut palm sunflower coconut oil extractor machine

capacity:20kg/h

input dia:less than 5mm

moisture:about 4%

motor:electric motor

raw material:sunflower seeds, soybean,rapeseeds,sesame etc

package:wooden case

After Warranty Service:Video technical support, Online support, Spare parts

Local Service Location:None

Certification:CE

20kg/h commercial small sesame peanut palm sunflower coconut oil extractor machine

Suitable type of Seed: soybean,almonds, sesame seeds, peanut, juglans,pine nuts,tea seeds , etc.

Raw material

This screw cold&hot press series can process sesame seed, rapeseed, peanut, soybean, cottonseed, almond, Tung-oil seed, sunflower seed, tea seed, walnut, caster seed, Perillaseed , Hazelnut,oil palm, oil olive, avocado, pomegranate seed , pistachio nut, neem seed, coconut, totally about 150 types of seeds , nuts,beans , fruits and oil crops;

Working priciple

Working priciple

vegetable oil processing plant/oil extracting machine/oil refinery machinepretreatment/pre-press equipment.

Elevator- shelling – elevator – cleaning -elevator – magnetic drum – flaking- elevator -cooking – pre-press- to extraction work

Advantage

1) Simple structure ,easy in installation and maintation. 2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 3) Running in a high automatization and intellectualization,no pollution 4) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine . 5) Suitable to losts raw materials such as peanut, sunflower seeds, black seeds, olive, coconut, flax seeds, etc.

Product Specification

Product Specification

| Model | TZ-60A | TZ-80A | TZ-100A | TZ-125A | TZ-150A |

| Screw diameter | 60mm | 80mm | 100mm | 125mm | 150mm |

| Capacity (kg/h) | 30-60 | 125-150 | 200-250 | 250-350 | 500-600 |

| Motor | 2.2kw | 5.5kw | 7.5kw | 15kw | 22kw |

| weight (kg) | 220 | 700 | 1100 | 1400 | 1700 |

|

Company Profile We are a China manufacturing and project engineering company with a global outlook, specializing in the design, production and supply of quality machines and integrated systems for the Edible Oil Production. Service Pre-sales service1.Quick response2.Detailed quotation3.Professional production and transportation solutionAfter-sales service1.Warranty policy one year from shipment2. We will send you the replacement after received the broken part3. Evaluate the customs risk and choose safest shipping company before shipping.4. Follow status up time by time until the goods arrived. FAQ Q1: Why choose us? A: We are a factory, not just a trading company. It has its own independent research and development team and production workshop,inspection and quality control procedures to ensure that each purchased product meets global quality standards. Custom services are also available Q2: What about your warranty? A: Our warranty is 1 year. Q3: Is there anyinstallation direction after we received the machine? A: Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time. |