Showroom Location:Viet Nam, Philippines, Indonesia

Condition:New

Type:Noodle, Grain Processing Equipment

Production Capacity:80000pcs/8h

Place of Origin:Henan, China

Brand Name:TaiXing

Voltage:380V

Power:80kw

Dimension(L*W*H):60*6*5.5m

Weight:according to the capacity

Warranty:1 Year

Marketing Type:New Product 2020

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Other

Key Selling Points:Automatic

Name:instant noodle making machine

Color:White

Product name:instant noodle making machine

Raw material:wheat flour

Application:Snack Food

Capacity:4800pcs/h

Quality:China Top

Material:Stainless Steel 304

Keywords:noodle making machine

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:Viet Nam, Philippines, Indonesia

After-sales Service Provided:Free spare parts

Certification:CE

40000pcs/h industrail fried instant noodle making machine line for factory

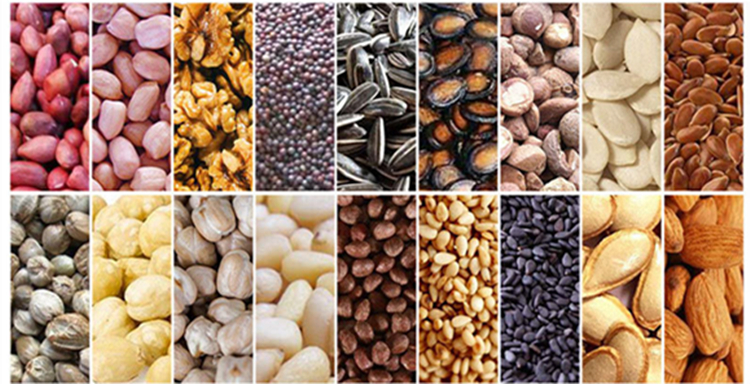

Although 6YL-68 Screw oil press machine is small in size, it boasts superior oil making capacity.It can be used for various materials such as Peanuts, Rape seeds, Sesame seeds, Soybeans, cottonseeds, Tea seeds, Tung Tree seeds, Sunflower seeds, Palm kernel, Coconut meat, Corn germ, Rice bran, Almonds, Black cumin, Cacao beans, Coffee beans, Hazelnuts, Hemp seed, Jatropha, Jojoba, Linseed, Mustard seeds, Black seeds, Palm nuts, Poppy seeds, Pumpkin seeds, Shea nuts, Walnuts,etc.

Raw material

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering, if buyer don’t need refinery, it also can be directly eat and sell, it is the most ideal individual small processing oil plant.

Working priciple

Working priciple

Structure of oil refining machine:1.small edible oil refinery machine structure:The machine is consist of hydration deguming&deacidification system, filter de-coloring, transmission system, oil liquid conveyingsystem, transmission and lubrication system, electrical control system and machine frame. 2.hydration deguming&deacidification system of our small edible oil refinery machine:This part is consist of mixer, deguming tank, gum outlet and transfer pipe3.filter de-coloring system of our small edible oil refinery machine:This part is consist of oil inlet, a sealing cover, cover handle, fine filter bucket, oil collecting tank, filter cloth, and oil outlet.4.transmission system of our small edible oil refinery machine:This part is consist of speed control motor, motor controller, governor and power module5.electrical control system of our small edible oil refinery machine:This part is consist of miniature circuit breaker, motor controller, power supply module, contactor, relay, potentiometer and knob.

Advantage

1) Simple structure ,easy in installation and maintation. 2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 3) Running in a high automatization and intellectualization,no pollution 4) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine . 5) Suitable to losts raw materials such as peanut, sunflower seeds, black seeds, olive, coconut, flax seeds, etc.

Product Specification

Product Specification

| Made in china seeds oil press machines/cottonseed oil expellerSpecification : | ||||

| Model | Capacity ( t/day) | Power(KW) | Outside Size(mm) | Weight(kg) |

| AST-80A | 2.5~3 | 5.5 | 1760*1050*1850 | 600 |

| AST-95CA | 3~5 | 7.5 | 2050*1050*1850 | 940 |

| AST-100A | 3~5 | 7.5 | 2050*1050*1850 | 940 |

| AST-120A | 4~7 | 11 | 2220*1050*1850 | 1200 |

| AST-120CA | 6~8 | 15 | 2340*1050*1850 | 1300 |

| AST-130A | 9~12 | 18.5 | 2450*1100*1950 | 1500 |

| AST-165A | 15~20 | 22 | 2600*1200*1950 | 1680 |

Company Profile

We are a professional manufacturer of various machines. Our products has been exported to more than 55 countries in the world. We have good faith in working with you and we are sure our team is one of your best Choices in China.

Service

1.Fast DeliveryWe are factory direct sale; we produce and export machine directly2.Competitive priceDirect raw material+cheaper labor= our competitive price3.On-time shipmentCredit&Quality is first! Machine is ready for our own sea/air shipping.4.Quality inspectionOwn advanced manufacturing equipments andcomputercontrolled making machine, so our factory implementassembly line entirely.5.QCStrict quality control system to guarantee 100% high quality.6.SincerityCooperation=whole life friendship. Not only the machine, but our Credit!

FAQ

Q: Why work with your company ?A: We have 40 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.Q: How can I judge your machine quality ?A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.Q: If i don’t know how to operate this machine ? How can i do ?A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.Q: What’s wear-in for new machine?A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.1. 1st hour, adjust oil cake thickness as 3 mm.2. 2nd hour, adjust oil cake thickness as 2.5 mm.3. 3rd hour, adjust oil cake thickness as 2 mm.Q:What are cold press and hot press?A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.Q:What service do you provide?A: (1) 1 year free warranty, whole lifetime maintenance.(2) Supplying wearing parts all year around.(3) Supplying technical solutions at any time.(4) Helping design and plan the oil plants construction.(5) Providing installation video.(6) Developing agents with good policies around world.